Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

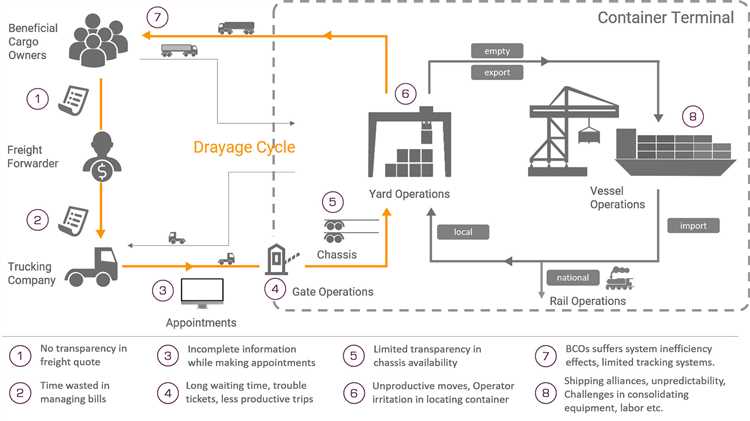

In the fast-paced world of container terminal operations, efficiency is crucial for economic success. Terminal operators face numerous challenges in balancing the demands of efficient handling and unloading of containers with the need for safety and contingency planning. To achieve optimal performance, strategies and solutions are needed to minimize delays and interference in the terminal workflow, while ensuring the efficient utilization of resources and equipment.

The integration of advanced technology and automation into terminal management systems has revolutionized container handling processes, offering significant savings in time and costs. By utilizing sophisticated software and monitoring systems, operators are able to forecast demand, optimize yard and equipment utilization, and improve the overall efficiency of the terminal. This not only results in increased operational performance, but also enhances the dependability and capability of the terminal to meet the demands of the supply chain.

One of the main challenges in terminal optimization is the reconciliation of economic constraints and safety requirements. While the primary goal is to achieve cost reduction and economic savings, it is essential to ensure the safety of personnel and equipment. A balanced approach is necessary to minimize risks and maintain a high level of safety, while maximizing the efficiency of operations. With the right strategies and planning, terminal operators can find the optimal balance between economic optimization and safety assurance.

Efficient yard and equipment management are key factors in terminal optimization. By implementing clustering techniques and efficient handling processes, operators can reduce idle time and improve the overall utilization of yard space and equipment. This not only allows for a more streamlined flow of containers, but also minimizes congestion and delays in the terminal. With proper monitoring and maintenance, operators can ensure the availability and reliability of equipment, further enhancing the economic efficiency of the terminal.

In conclusion, terminal optimization requires a comprehensive approach that combines strategic planning, advanced technology, and efficient management practices. By balancing economic optimization with safety considerations, terminal operators can achieve significant improvements in performance and cost savings. With the constant evolution of logistics and the increasing demands of the supply chain, terminal operators must continue to adapt and innovate to stay ahead in the competitive port industry.

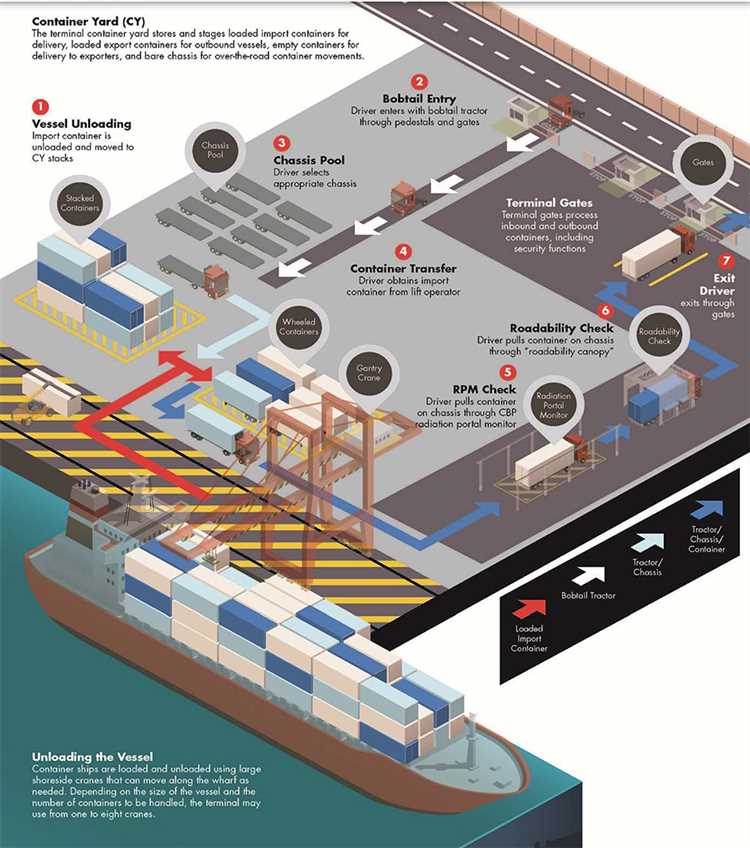

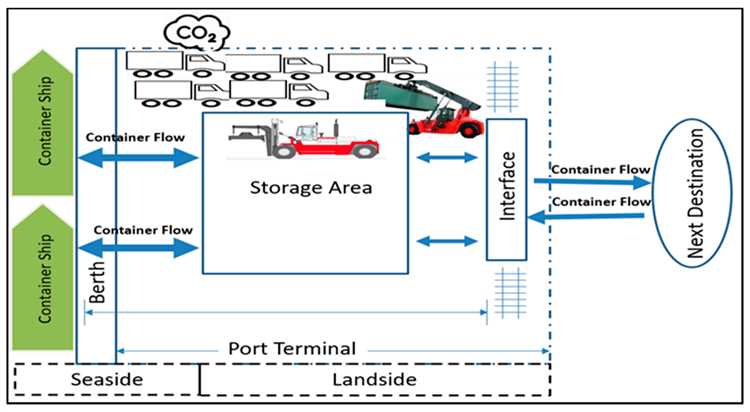

A container terminal is a critical component of the intermodal logistics system. It serves as a hub where goods are stored, sorted, and transferred between different modes of transportation, such as ships, trucks, and trains. It is a complex infrastructure that requires efficient management to ensure the smooth flow of goods.

Terminal Economic Optimization

Terminal economic optimization involves maximizing the profitability and efficiency of container terminals. It is achieved through the application of various strategies and technologies, such as advanced software systems and integration of operations. The ultimate goal is to balance the demand and supply of container handling services, while reducing costs and improving overall performance.

Efforts are made to optimize terminal processes and minimize interference or delays. This includes monitoring and analyzing the performance of the terminal’s equipment and resources. By identifying bottlenecks and areas for improvement, terminal operators can implement solutions that enhance efficiency and reduce unloading and storage time for cargo.

Challenges and Feasibility

However, optimizing terminal economics is not without its challenges. The large-scale and complex nature of container terminals, along with the unpredictability of shipping demand, make it difficult to achieve optimal results consistently. Terminal operators must reconcile conflicting interests and find a balance between maximizing capacity and ensuring safety and dependability.

The feasibility of optimization strategies also depends on the existing terminal infrastructure and available resources. Upgrading and expanding terminals can be costly and time-consuming, requiring careful planning, investment, and coordination with various stakeholders.

Container Terminal Optimization Solutions

To address these challenges, various solutions have been developed to improve the economic performance of container terminals. These solutions involve simulation models that allow terminal operators to test different scenarios and evaluate the impact of changes before implementation.

One approach is to optimize the scheduling of vessel arrivals and departures, taking into account factors such as container capacity, equipment availability, and shipping demand. By balancing the workload and reducing waiting times, terminal efficiency can be improved, leading to increased profitability.

Another strategy is to optimize the allocation of terminal resources, such as cranes and trucks, through clustering and storage optimization techniques. By grouping containers based on their destination or shipping line, resources can be utilized more efficiently, reducing handling costs and improving turnaround times.

In conclusion, container terminal economic optimization is a complex and ongoing effort. It requires careful analysis, planning, and implementation of various strategies and technologies. By continuously striving for efficiency and flexibility, terminal operators can maximize their profitability and contribute to the overall success of the logistics industry.

The importance of terminal economic optimization cannot be overstated in today’s fast-paced shipping industry. As container terminals become increasingly busy and complex, finding solutions to optimize their economic performance is essential for ports and shipping companies. Economic optimization involves various strategies and techniques, aimed at improving efficiency, reducing delays, and balancing supply and demand.

One key aspect of terminal economic optimization is optimizing equipment and resources. By carefully scheduling and clustering vessel arrivals and departures, terminal operators can maximize the use of their equipment and minimize idle time. Additionally, effective cargo storage and yard management strategies can ensure that containers are readily accessible, reducing the time required for retrieval and delivery.

Flexibility is another crucial element in terminal economic optimization. By having contingency plans in place and utilizing advanced software solutions, terminals can quickly adapt to changing demands and unforeseen events, such as vessel delays or equipment breakdowns. This flexibility allows for efficient resource allocation and optimal utilization of infrastructure.

Monitoring and forecasting are also integral to terminal economic optimization. By continuously monitoring performance metrics and analyzing historical data, terminals can identify patterns and trends to better forecast future demand. This enables them to plan their operations and allocate resources effectively, ensuring that they can meet customer needs while minimizing costs and reducing the risk of bottlenecks.

Automation plays a significant role in terminal economic optimization. By automating certain processes, such as container handling and maintenance, terminals can improve efficiency and reduce the effort required from human operators. Automation also enhances safety, as it minimizes the risk of human error and increases the accuracy and speed of operations.

In conclusion, terminal economic optimization is of utmost importance in today’s shipping industry. By striving for efficient and effective operations, ports and terminal operators can improve their performance, reduce costs, and meet the increasingly demanding needs of the shipping market. From equipment optimization to forecasting and automation, terminal economic optimization encompasses a wide range of strategies and techniques that contribute to the overall success of a container terminal.

The efficient operation of a container terminal is crucial for the smooth flow of goods in the global supply chain. However, this process is not without its challenges. One key challenge is the need to optimize terminal performance in order to maximize profit and minimize costs. This involves finding the optimal routing and allocation of resources, such as the terminal’s fleet of handling equipment, in order to minimize delays and interference.

Another challenge is the need to ensure the safety of all operations within the terminal. Container handling can be a complex and potentially hazardous process, so it is important to implement and enforce strict safety protocols. This includes regular monitoring and analysis of terminal operations to identify potential safety risks and take appropriate measures to mitigate them.

Furthermore, container terminals are subject to various constraints and feasibility considerations. These include factors such as the availability of land and infrastructure, as well as regulatory and environmental requirements. Terminal operators must carefully analyze these constraints and develop feasible solutions that meet all necessary criteria.

Terminal economic optimization is also a significant challenge in container terminal operations. This involves finding ways to improve overall efficiency and reduce costs, such as through automation and system optimization. By streamlining processes and minimizing unnecessary handling, terminal operators can achieve greater operational efficiency and generate savings.

In addition, forecasting and inventory management are important aspects of terminal economic optimization. Accurate forecasting of container volumes can help terminal operators plan for optimal resource allocation and minimize unnecessary costs. Effective inventory management can also help reduce handling and storage costs, leading to improved profit margins.

In conclusion, container terminal operations face various challenges, ranging from the efficient planning and routing of resources to the implementation of safety measures. Terminal economic optimization is a key goal in addressing these challenges, with a focus on improving efficiency, reducing costs, and maximizing profit. By implementing the right strategies and solutions, terminals can overcome these challenges and achieve optimal performance and service dependability in the shipping industry.

Efficient yard management strategies are crucial for optimizing the economic performance of container terminals. The handling and storage of cargo in the yard can greatly impact the efficiency and cost-effectiveness of operations. One effective strategy is clustering, which involves grouping containers with similar destination or delivery time frames together. This helps to streamline the routing and integration of containers, reducing delays and improving overall efficiency.

Another key aspect is the optimization of yard infrastructure and processes. Terminal operators need to ensure that their yard layout and equipment are designed and maintained in a way that maximizes efficiency and safety. Regular analysis and reconciliation of container inventory is essential in order to identify any discrepancies and minimize losses. The use of advanced software solutions can also greatly enhance yard management by providing real-time data and forecasting tools for capacity planning and fleet management.

Efficient yard management also requires effective intermodal logistics and coordination with other supply chain partners. Seamless integration between different modes of transportation, such as trucking, rail, and sea, can help to minimize handling and transportation costs. Terminal operators should make efforts to align their operations with the demand patterns of the market, ensuring that they are able to provide a reliable and timely service to their customers.

By implementing these yard management strategies, container terminals can improve their performance, reliability, and cost-efficiency. They can achieve significant savings in terms of time, inventory, and resources, while also enhancing the overall customer experience. However, it is important to recognize that yard management optimization is an ongoing process, as terminals must constantly adapt to changing market conditions and emerging challenges.

Automation and technology play a crucial role in improving the efficiency and performance of terminal operations. Through the use of advanced software systems, terminals can optimize their processes and minimize delays. They can also forecast and schedule necessary maintenance tasks to ensure the reliability of equipment and minimize downtime.

Automated systems can also help in balancing the utilization of terminal resources, such as vessels and containers, to maximize efficiency. Through simulation and integration, terminals can avoid interference and optimize the scheduling of unloading and transportation tasks. With the capability to cluster different operations and consider logistical constraints, terminals can improve service and reduce the time it takes to process shipments.

The integration of automation and technology in terminal operations also brings safety benefits. Software solutions can analyze data and identify potential obstacles or risks in the terminal environment. By implementing predictive maintenance and contingency plans, terminals can ensure the safety of both workers and equipment.

From a financial perspective, automation and technology can significantly contribute to terminal economic optimization. By improving productivity and reducing delays, terminals can increase their profit margins. They can also enhance their forecasting capabilities, allowing them to plan for future demand and make informed business decisions.

In conclusion, automation and technology are crucial components in achieving terminal economic optimization. Through efficient utilization of resources, improved scheduling, and enhanced safety, terminals can optimize their operations and maximize their profitability. By embracing the latest technological advancements, terminals can stay ahead of the competition and provide excellent service to their customers in the shipping industry.

The optimization of berth allocation plays a crucial role in the economic optimization of a container terminal. Efficient allocation of berths enables better utilization of resources, leading to cost savings and improved productivity. Terminal operators must carefully plan and allocate berths to ensure that containers are stored, maintained, and unloaded in an optimal manner.

By optimizing berth allocation, terminals can improve their yard layout, inventory management, and container handling processes. This optimization is achieved through the integration of software systems, simulation technology, and reliable data to balance container demand and terminal capacity. This aids in the efficient planning of container unloading schedules, fleet operations, and transportation resources.

Terminal economic optimization involves finding strategies to maximize profit and overall efficiency. This is achieved by reconciling the conflicting goals of minimizing costs and maximizing revenue. The optimization process considers factors such as terminal performance, network efficiency, and the feasibility of implementing various strategies.

Terminal operators can optimize their economic performance by improving process efficiency, reducing costs through resource optimization, and ensuring the safety and dependability of operations. By implementing optimal strategies, terminals can achieve higher levels of productivity, cost savings, and customer satisfaction.

The use of advanced technology and software systems enables operators to optimize their terminal operations. These tools aid in analyzing and simulating different scenarios, identifying bottlenecks, and identifying areas for improvement. Through the optimization of various aspects, including yard planning, cargo handling, and supply chain integration, terminals can enhance their efficiency and profitability.

In conclusion, the optimization of berth allocation and terminal economic optimization are critical for the success of container terminals. By integrating technology, optimizing processes, and strategically planning operations, terminals can achieve higher levels of efficiency, cost savings, and overall performance.

In order to achieve optimal Terminal Economic Optimization, it is essential to maximize berth productivity at a container terminal. Berth productivity refers to the efficient utilization of terminal resources to ensure the smooth flow of containerized cargo through the terminal. However, there are several obstacles to achieving maximum berth productivity, including constraints such as limited capacity, inefficient planning and scheduling processes, and unreliable transportation.

One effective solution to overcome these obstacles is through the implementation of advanced technology and automation systems. By utilizing these technologies, terminals can improve their planning and forecasting capabilities, optimize their resource allocation, and enhance their operational efficiency. This ensures that all processes, from container arrival and storage to retrieval and onward transportation, are carried out in a coordinated and timely manner.

In addition, flexibility and contingency planning play a crucial role in maximizing berth productivity. Container terminals need to have the capability to adapt to sudden changes in demand, unexpected disruptions, or the need for additional capacity. By having a well-designed infrastructure and an optimized network, terminals can easily adjust their operations and resources to meet changing demands and ensure a smooth flow of cargo.

Furthermore, safety and security concerns should be a top priority in terminal operations optimization. Implementing robust safety measures, monitoring systems, and inventory management solutions not only ensure the protection of assets and cargo but also contribute to overall efficiency and reliability. By preventing accidents and optimizing inventory levels, terminals can reduce costs and minimize downtime.

To summarize, maximizing berth productivity is a critical aspect of Terminal Economic Optimization. By implementing efficient planning and scheduling processes, utilizing advanced technologies, enhancing infrastructure and resources, and prioritizing safety and security, container terminals can overcome obstacles, improve their operational efficiency, and achieve maximum productivity and optimization.

Efficient cargo handling is crucial for terminal economic optimization. Balancing logistics and savings is essential for ensuring the smooth and cost-effective handling of cargo. By improving container clustering, routing, and scheduling, terminals can enhance their productivity and capacity while reducing costs.

Maintenance and forecast monitoring are key factors in effective cargo handling. Predicting the demand and properly maintaining the equipment and infrastructure can help terminal operators optimize their resources. Through careful analysis of constraints and simulation, terminals can identify obstacles and find solutions for their efficient cargo handling processes.

Implementing advanced technology and automation can greatly improve terminal economic optimization. Integration of optimal systems and intermodal transportation can lead to cost reduction and enhanced safety. By employing innovative management and process techniques, terminals can streamline their operations and provide better service to their customers.

Terminal managers should also focus on the reconciliation of their cargo handling schedules with the overall terminal schedule. This ensures a smooth flow of cargo and avoids unnecessary delays. By constantly monitoring and analyzing the performance of their operations, terminals can identify areas for improvement and implement strategies to optimize their economic output.

In conclusion, effective cargo handling techniques play a vital role in terminal economic optimization. By utilizing technology, implementing efficient management processes, and continuously analyzing and improving their operations, terminals can achieve higher productivity, reduce costs, and provide better service to their customers.

Effective scheduling and optimization are key strategies for improving terminal economic optimization and streamlining terminal logistics. By utilizing advanced software and predictive analytics, terminals can better forecast and monitor delays, resulting in improved reliability and dependability. This capability allows for better planning and balancing of resources, reducing costs and improving overall efficiency.

In order to achieve economic optimization, terminals must also address obstacles such as unpredictability in cargo volume and inventory levels. By implementing solutions that allow for flexibility and contingency planning, terminals can effectively handle fluctuations in demand and ensure that resources are properly aligned.

Integration with intermodal transportation and the port infrastructure is also critical for terminal economic optimization. By effectively coordinating with other modes of transportation, terminals can reduce transportation costs and improve profit margins. This integration requires the use of innovative equipment and technologies that allow for seamless handling and reconciliation of cargo.

The safety and handling of cargo within the terminal is another important consideration for economic optimization. By implementing safety protocols and ensuring efficient and secure handling processes, terminals can minimize delays and ensure the reliability of cargo movement.

In conclusion, optimizing terminal economics requires a comprehensive approach that includes effective scheduling, optimization strategies, flexibility, and integration with other modes of transportation. By addressing the challenges and obstacles that terminals face, implementing innovative solutions, and prioritizing safety and reliability, terminals can achieve economic optimization and improve overall efficiency.

In the context of container terminal optimization, one crucial aspect that cannot be overlooked is environmental sustainability. Terminal operations have a significant impact on the environment, and finding solutions to make them more sustainable is essential for long-term success.

Efficiency is the key to achieving environmental sustainability in terminal operations. By optimizing processes and utilizing resources in the most efficient way, terminals can minimize their environmental footprint. This optimization includes efficient planning and utilization of yard space, vessel berthing, and container handling, among other aspects.

Challenges such as delays, limited infrastructure, and varying demand levels can hinder the optimal economic performance of a container terminal. However, by implementing strategies focused on balancing the demand and forecast, terminals can achieve better utilization and integration of their resources. This enables them to operate more efficiently, leading to improved profitability and reduced environmental impact.

Terminal operators need to prioritize safety in their operations, as it directly affects the overall performance and sustainability of the terminal. Maintaining a safe working environment not only ensures the well-being of the workers but also prevents accidents that can result in costly delays and damage to containers, vessels, and other assets.

Monitoring and reconciling inventory and container movements is another crucial aspect of terminal operations. By implementing efficient tracking systems and processes, terminals can minimize the risk of container losses or misplacement, reducing unnecessary resource allocation and improving overall dependability and reliability.

Moreover, environmental sustainability in terminal operations requires constant monitoring and feasibility analysis of new technologies and solutions. Terminals must stay updated on advancements in container logistics and shipping to identify opportunities for improvement and implement sustainable practices. Flexibility in adopting new innovations and integrating them into the terminal’s existing infrastructure is essential for long-term sustainability.

In conclusion, achieving environmental sustainability in terminal operations is a complex process that requires a comprehensive examination of various factors. By prioritizing efficiency, safety, and innovation, terminals can optimize their economic performance while minimizing their environmental impact. This process involves strategic planning, constant monitoring, and a commitment to balancing economic optimization and environmental stewardship.

The future of container terminal optimization lies in the development of innovative solutions and the efficient management of resources. With the increasing demand for container transportation, it is essential for terminals to improve their operations to meet the growing needs of the industry. This can be achieved through the effective optimization of processes, infrastructure, and technology.

One of the key trends in terminal optimization is the use of advanced technologies. Through the implementation of sophisticated systems, such as simulation and analysis tools, terminals can identify areas for improvement and develop strategies to optimize operations. This can lead to significant savings in terms of time, cost, and resources.

Another important trend is the optimization of storage and handling capacity. By adopting efficient equipment and ensuring proper maintenance, terminals can increase their capacity to handle containers and improve overall efficiency. This can result in reduced handling time, improved reconciliation of schedules, and increased profitability for the terminal.

In addition to technology and capacity optimization, container terminal operators are also focusing on safety and environmental sustainability. Through the implementation of safety protocols and the use of eco-friendly equipment, terminals can ensure the well-being of their workers and minimize the negative impact on the environment.

Furthermore, terminals are exploring innovative solutions such as clustering and network optimization to improve the overall performance and profitability of the container terminal. By effectively managing the interference between different processes and optimizing the utilization of resources, terminals can achieve a better balance between supply and demand, leading to improved economic optimization.

In summary, the future of container terminal optimization lies in the adoption of advanced technology, efficient management of capacity, safety, and environmental sustainability. By continuously improving systems and processes, terminals can enhance their profitability, meet the increasing demands of the industry, and contribute to the overall efficiency of the logistics network.

The future trends in container terminal optimization include the use of advanced technology such as automation, artificial intelligence, and big data analytics. These technologies will improve efficiency, productivity, and reduce costs in container terminals.

Automation will greatly impact container terminal optimization by reducing manual labor, improving operational efficiency, and reducing human errors. It will also increase the overall throughput of container terminals.

Artificial intelligence plays a crucial role in container terminal optimization by analyzing large amounts of data and making predictions and recommendations for optimal decision-making. AI can optimize container movements, improve scheduling, and enhance overall terminal performance.

Big data analytics will benefit container terminal optimization by providing insights into various aspects of terminal operations such as container flow, yard utilization, and vessel scheduling. It will help identify bottlenecks, optimize resource allocation, and improve overall operational efficiency.

Some challenges in implementing container terminal optimization include high implementation costs, resistance to change from existing manual processes, and the need for skilled personnel to manage and operate the advanced technologies. However, the benefits of optimization outweigh these challenges in the long run.

Container terminal optimization will have a significant impact on the global supply chain by improving the efficiency and speed of cargo handling, reducing transit times, and lowering overall logistics costs. It will enable smoother and more efficient movement of goods from production to consumption.