Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

A reach stacker (RST) is a versatile and powerful piece of equipment used in the transportation and handling of containers. With its battery-powered engine and wheel-based design, the reach stacker is capable of efficiently lifting and transporting containers within a port or distribution yard.

The key feature of a reach stacker is its lifting mechanism, which utilizes hydraulics to hoist containers off the ground and stack them on top of each other. This allows for easy loading and unloading of containers from ships and other modes of transport, making it an essential tool in the logistics and transport industry.

One of the unique capabilities of a reach stacker is its ability to counterbalance the weight of the containers it is lifting. This enables the reach stacker to handle heavy loads without tipping over, ensuring safe and efficient operations. With its articulated chassis and telescopic spreader, it can easily maneuver in tight spaces and position containers precisely.

The reach stacker’s control center, located in the operator’s cab, provides the operator with full control over the machine. The operator can use the controls to perform various operations such as driving, stacking, and rotating the containers. The reach stacker is also equipped with spreader bars, slings, and rigging equipment for handling bulk and oversized cargo, such as logs and heavy machinery.

With its efficient handling capabilities and versatile design, the reach stacker plays a crucial role in the transportation and stowage of containers on both bulk vessels and roll-on/roll-off (Ro-Ro) ships. It is commonly used in large ports and distribution centers to efficiently move containers from one location to another, improving overall intralogistics and supply chain management.

In conclusion, the reach stacker is the ultimate container handler loader, providing a reliable and efficient solution for the transportation, handling, and loading of containers. Its powerful lifting mechanism, advanced control system, and versatile design make it an essential piece of equipment in the logistics and transport industry.

A reach stacker is a specialized piece of equipment used in terminals and distribution centers for handling and stacking containers. It is designed to reach containers that are stacked in multiple rows and lift them using a hydraulic gantry system. This allows for efficient loading and unloading of containers from trucks, trailers, and other vehicles.

The reach stacker is equipped with a hook or spreader attachment that can be adjusted to accommodate different container sizes. It is a mobile handling machine that is typically powered by a diesel or electric engine. The reach stacker has multiple wheels for stability and maneuverability, allowing it to stack containers in tight spaces and navigate around obstacles.

One of the key advantages of a reach stacker is its ability to handle both containerized and breakbulk cargo. It can lift and stack containers of various sizes and weights, as well as other types of bulk and packaged materials. This versatility makes it a valuable asset in ports, warehouses, and other logistics operations.

The reach stacker is operated by a skilled operator who controls the machine from a cab located at the center of the vehicle. The operator uses the boom and hook/spreader to lift and move containers, ensuring their safe placement and stability during transportation. The reach stacker can also be equipped with automation features for improved efficiency and safety.

In addition to its use in loading and unloading containers, the reach stacker is also used for transshipment, inventory management, and warehousing. It can transport containers from the storage yard to the loading bay, stack them in designated areas, and retrieve them when needed. This helps optimize the flow of goods and streamline intralogistics operations.

Overall, the reach stacker plays a crucial role in the shipping and logistics industry. It is a powerful and versatile piece of equipment that enables efficient handling and transportation of containers, improving the efficiency of supply chains and ensuring timely delivery of goods.

A container handler loader, also known as a reach stacker, is a specialized automation vehicle used for the efficient handling of containers. It is designed to transport, stack, and load containers onto ships, trucks, or trains for transportation. The main purpose of a container handler loader is to streamline the containerization process, making it more efficient and reducing the time and effort required for loading and unloading containers.

This equipment is equipped with a conveyor system and a telescopic boom that allows it to reach and lift containers in a controlled manner. It is powered by an electric battery, ensuring a greener and more environmentally-friendly operation. With its articulated chassis and counterbalance mechanism, container handler loaders are capable of navigating tight spaces and maintaining stability while handling heavy loads.

Container handler loaders play a vital role in the shipping and transportation industry, as they are essential for the smooth operation of ports, depots, and transshipment stations. They are used to load and unload containers from vessels, transport them within the yard, and stack them in an organized manner to optimize space. Additionally, they are used for inventory management, ensuring accurate tracking and storage of containers.

These machines are equipped with various attachments such as clamps or forks, allowing them to handle different types of cargo, including bulk, pallets, and machinery. The hydraulics and stabilizers of the equipment provide precise control and stability during handling operations.

The container handler loader is an integral part of the intralogistics and warehousing industry, as it ensures efficient and streamlined container handling, reducing the time, effort, and cost associated with transportation and packaging. It is a mobile and versatile piece of equipment that plays a crucial role in the intermodal transportation of goods, facilitating the movement of containers between different modes of transportation such as trucks, trains, and ships.

A container handler loader, also known as a reach stacker, is a versatile and powerful machine designed specifically for efficient and safe handling of containers in a terminal or port. It offers several key features that make it the ultimate container handler loader in the shipping industry.

The container handler loader is equipped with advanced automation and control systems that enable precise and efficient handling of containers. The operator can easily control the machine using intuitive controls, ensuring smooth and accurate material handling operations.

The reach stacker is capable of stacking containers and ensuring their stability during transportation. It features telescopic spreaders, hoists, and clamps that can securely lift and stack containers, even in challenging weather conditions.

Many container handler loaders are electrically powered and use rechargeable batteries, making them eco-friendly and cost-effective to operate. The electric powertrain also provides quiet operation and reduced emissions, making them ideal for terminal operations in urban areas.

The reach stacker enables efficient stowage and containerization of cargo, allowing for easy organization and retrieval of containers in the terminal. It also offers features for tracking and managing inventory, optimizing the overall logistical efficiency.

The reach stacker can handle various types of containers, including breakbulk, bulk, and intermodal containers. It can also handle other equipment, such as rigging and spreader bars, making it a versatile machine for different cargo handling tasks.

The reach stacker is equipped with advanced stability and driving features, including retractable stabilizers and center of gravity optimization. This ensures safe and stable driving, even on uneven terrain or during tight maneuvers in the terminal.

The container handler loader features efficient loading and unloading capabilities, allowing for quick and seamless transfer of containers between ships, trucks, and wagons. It also has a conveyor system for bulk cargo handling, further enhancing its versatility.

In conclusion, the container handler loader, or reach stacker, offers a wide range of key features that make it the ultimate solution for efficient and safe container handling in terminals and ports. Its automation, stacking capabilities, electric power, storage optimization, versatility, and safety features make it an essential machine in the shipping and warehousing industry.

A reach stacker is a versatile container handler loader used in the shipping industry to efficiently handle containers. It combines the functions of a crane, transport vehicle, and forklift to facilitate containerization and distribution.

The reach stacker operates by using its hydraulic system to lift and move containers. It is equipped with straddle legs or container handling forks that allow it to pick up and stack containers in a wide range of racking systems. The reach stacker has articulated steering, which gives it the flexibility to maneuver in tight spaces. It also has a platform with tires that provide stability while loading and unloading containers.

When a container is being picked up, the reach stacker positions itself and uses its lifting mechanism to secure the container. It then transports the container to the desired location, whether it is a storage yard, a warehouse, or a terminal. In some cases, the reach stacker may also be involved in transshipment operations, where containers are transferred between different modes of transportation, such as ships, trains, or trucks.

The reach stacker is operated by a skilled driver who uses specialized controls to manipulate the machine. These controls allow the driver to precisely stack containers and ensure their stability. The reach stacker can also be equipped with additional attachments, such as a log handler or a cargo attachment, to handle specific types of loads.

In summary, a reach stacker is a powerful and efficient machine used in the shipping and logistics industry. It plays a crucial role in container handling, warehousing, and distribution operations. With its hydraulic system, versatile capabilities, and skilled operators, the reach stacker ensures smooth and efficient material transport and handling throughout the supply chain.

Reach stackers are versatile and efficient container handling loaders that are commonly used in logistics and transportation operations. They come in different types, each designed to cater to specific needs and requirements.

One type of reach stacker is the electric reach stacker, which operates on an electric motor. This type of reach stacker is environmentally friendly and offers lower operating costs compared to its counterparts. It is ideal for operations that prioritize sustainability and energy management.

An articulated reach stacker is another type that features an articulated chassis design, allowing for maximum maneuverability in tight spaces and busy ports or warehouses. The operator can easily navigate the stacker around obstacles and efficiently handle containerized shipments, optimizing space utilization.

A mobile reach stacker, on the other hand, is designed for ease of transportation and deployment. It can be quickly transported to different locations, enabling efficient handling of containers during transshipment operations.

The heavy-duty reach stacker is specifically built for handling larger and heavier containers. Equipped with strong hydraulics and a robust chassis, it has the lifting capacity and stability required for the handling of heavy freight.

Reach stackers also come with different types of mechanisms for efficient container handling. The retractable wheel mechanism allows for easy repositioning of the stacker, while the hoisting and stabilization mechanisms ensure secure loading and unloading of containers.

For specialized needs, there are reach stackers equipped with additional equipment such as forklift attachments or rigging equipment. These attachments enable the reach stacker to handle a wider range of materials and facilitate intermodal operations.

In summary, reach stackers offer a range of options for container handling and logistics operations. From electric reach stackers to heavy-duty and mobile ones, these machines provide efficient and automated solutions for loading, unloading, and stacking containers.

A single-container reach stacker is a specialized crane used in the intermodal industry for efficient container handling and loading. It is commonly used in yards, depots, and terminals to facilitate the movement of containers in intralogistics and transportation operations. Equipped with a powerful hoisting system, this mobile equipment is capable of lifting heavy cargo containers with precision and ease.

The reach stacker is designed to handle containerized shipments, making it an essential tool for containerization and distribution centers. With its retractable chassis and stabilizers, it can easily stack containers and load them onto various types of transport vehicles, including ships. The versatile hook and rigging system allow for smooth rotation and placement of containers, optimizing loading and unloading operations.

Powered by advanced hydraulics and a battery-operated motor, the reach stacker offers efficient and eco-friendly performance. Its robust chassis, sturdy tires, and counterbalance design ensure stability and safety during operation. With the operator seated in a spacious and ergonomic cab, the reach stacker provides excellent visibility and control, enhancing overall efficiency.

Whether used in a warehouse or a terminal, single-container reach stackers play a vital role in the management of containerized shipping. They enable smooth and timely dispatch of containers, minimizing bottlenecks and delays. The precise handling and loading capabilities of this equipment make it an indispensable tool for stevedores and logistics companies involved in intermodal transportation.

In summary, the single-container reach stacker is an essential piece of equipment in the shipping industry. Its efficient loading and handling capabilities, along with its versatile features, make it a valuable asset for managing containerized cargo. Whether in a distribution center or a terminal, this crane ensures smooth operations and optimal use of space. With its advanced hydraulics, sturdy construction, and ergonomic design, the reach stacker is a reliable choice for container handling and loading needs.

The multi-container reach stacker is a highly efficient and versatile piece of equipment designed for the handling, loading, and unloading of containers. It is equipped with strong tires for stable and smooth movement across various terrains in ports, depots, and warehouses.

With its 360-degree rotation capability, the reach stacker allows for easy maneuvering and precise placement of containers. The hook and hoist mechanism enable the operator to lift and lower containers and freight with ease, ensuring efficient loading and unloading operations.

The reach stacker is specially designed to handle breakbulk cargo, providing safe and secure stowage of items with the help of its sturdy forks and hydraulics. It can handle multiple containers simultaneously, making it an essential machinery in the logistics and warehousing industry.

The reach stacker is widely used in ports and container terminals to efficiently stack containers on ships and stack them in storage yards. Its telescoping boom and retractable spreader allow for the efficient handling of containerized cargo, ensuring quick and accurate placement.

Thanks to its advanced control system, the reach stacker offers precise driving and maneuvering capabilities, making it suitable for narrow spaces and busy port environments. It can also perform straddle and intermodal operations, seamlessly transferring containers between different modes of transportation such as trucks and trailers.

With its powerful hoisting and lifting mechanism, the reach stacker can handle heavy containers with ease. Its counterbalance design ensures stability and safety during operations, while the platform provides a secure working area for the operator.

The reach stacker plays a crucial role in shipping and logistics management, as it enables fast and efficient handling of containers, improving inventory management and reducing turnaround times. It is operated by trained personnel who ensure the safe and efficient movement of containers, ensuring smooth operations in ports and container terminals.

Overall, the multi-container reach stacker is a reliable and efficient piece of equipment that revolutionizes the handling and loading of containers. Its versatility, maneuverability, and powerful hydraulic system make it an essential tool for the logistics industry, ensuring smooth and efficient operations in port and warehouse settings.

Using a reach stacker, a heavy container handler loader, comes with numerous benefits in containerization and logistics operations. This powerful machine offers efficient stacking and storage capabilities, making it an indispensable tool in the transportation and warehousing industry.

In conclusion, the reach stacker is a versatile and essential machine for efficient container handling and transportation. Its role in containerization, warehousing, and logistics operations cannot be understated, as it offers significant benefits in terms of efficiency, productivity, cost savings, safety, and overall logistics optimization.

The use of reach stackers as container handler loaders has greatly increased the efficiency of operations in ports and container yards. These vehicles are equipped with forks and a hoist mechanism that allows for the easy lifting, carrying, and stacking of containers. By utilizing the reach functionality, these machines can access even the innermost containers in a stack, reducing the time and effort required for container picking and stowage.

With the ability to rotate 180 degrees, reach stackers can easily load and unload containers from trailers, trucks, and wagons. The versatile operation of these machines allows for efficient loading and unloading of containers onto ships, ensuring smooth vessel operations. The hydraulic transmission system ensures precise control and smooth maneuverability, improving the overall handling of containers.

In addition to their container handling capabilities, reach stackers also contribute to efficient warehousing operations. The mobile nature of these machines enables operators to quickly transport containers from the yard to the storage location, streamlining the process of container stuffing and retrieval. This eliminates the need for additional equipment, such as pallet trucks or conveyors, for material handling within the warehouse.

Another advantage of reach stackers is their battery-powered operation, reducing the emissions and noise levels associated with traditional diesel-powered machines. This allows for improved environmental sustainability and a more pleasant working environment for operators and personnel. Furthermore, the retractable spreader and stabilizing wheel provide added stability and safety during the stacking and handling of containers.

Overall, the use of reach stackers as container handler loaders has revolutionized the process of container handling and transportation. The increased efficiency and versatility of these machines have greatly improved the speed and accuracy of operations in ports, container yards, and warehouses, making them the ultimate choice for container handling and loading.

The container handler loader, also known as the reach stacker (RST), is a highly versatile piece of equipment that plays a crucial role in the logistics industry. With its advanced hydraulics and precise control mechanisms, the RST is designed to handle various tasks related to container handling, unloading, and loading operations.

One of the key features of the container handler loader is its ability to handle different types of containers, such as those used in shipping, packaging, and storage. The RST is equipped with a hydraulic spreader, which allows it to securely grab and lift containers, ensuring safe transportation and stowage. Its sturdy chassis and stabilization mechanism guarantee stability during the lifting and stacking process.

The reach stacker’s versatility extends beyond container handling. It can also be used for other operations, such as breakbulk cargo handling, dispatch, and transshipment. The RST is equipped with various attachments, including clamps and spreader beams, which enable it to handle a wide range of cargo, including pallets, machinery, and even oversized shipments.

Additionally, the reach stacker is highly mobile and flexible, making it ideal for use in terminals and depots. Its counterbalance design and telescopic boom allow it to easily maneuver in tight spaces and reach containers at different heights. Furthermore, the RST is equipped with battery-powered hydraulics, minimizing noise, emission, and maintenance requirements.

In conclusion, the versatility of the reach stacker, or container handler loader, makes it an indispensable piece of equipment in the field of logistics and containerization. Its ability to handle various types of cargo, efficient control mechanisms, and mobile capabilities make it an essential tool for efficient and effective cargo management and stevedoring operations.

The introduction of the Reach Stacker (RST) has significantly improved safety in container handling and loading operations at terminals, CFS warehouses, and other logistics facilities. This electric-powered equipment combines the functionality of a crane, forklift, and trailer, providing a versatile solution for efficient container handling.

The RST operator sits in a centrally positioned cabin, equipped with controls that enable precise maneuvering and stacking of containers. This enhances safety by reducing the risk of accidents caused by human error or inadequate visibility. With its 360-degree rotation capability, the RST eliminates blind spots, allowing operators to maintain clear views of their surroundings.

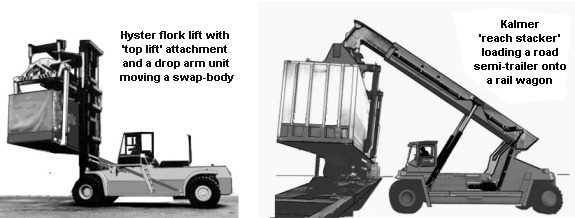

Equipped with spreader arms and forks, the RST can pick up containers from ground level, transferring them to different platforms, such as trailers or rail wagons. The hydraulic-powered mechanism ensures the secure and stable positioning of containers during transportation and stacking.

The RST’s counterbalance design, sturdy chassis, and spread tires provide stability when driving on uneven surfaces. This feature is crucial for operations in ports and other container handling facilities where the ground may not always be level. Furthermore, the RST’s advanced controls and stabilization system enable smoother stacking and unloading of containers, minimizing the risk of accidents and damage to goods.

In addition to its safety features, the RST improves operational efficiency by reducing the need for additional equipment, such as cranes or forklifts. Its versatility allows for efficient handling of various container sizes and types, including breakbulk and overweight containers.

Overall, the introduction of the Reach Stacker has revolutionized container handling and loading operations, providing safer and more efficient solutions for the shipping and logistics industry.

When choosing a reach stacker, there are several important factors that need to be taken into consideration. One of the key considerations is the type of equipment needed for the specific handling requirements. Reach stackers are specifically designed for containerized freight and material handling, making them a popular choice for intralogistics operations.

Operating capabilities are another crucial factor to consider. A reach stacker should have the ability to efficiently lift and stack containers, as well as handle other cargo such as pallets and articulated wagons. It should also have a reliable transmission system and stabilizers to ensure safe and smooth operations.

The size and weight of the reach stacker are also important considerations. Heavy-duty reach stackers are capable of handling larger containers and heavier loads, while smaller models are more suitable for smaller containers and lighter loads. The type of tires used on the reach stacker is also important, as they should be able to withstand the weight and provide optimal traction for various terrain conditions.

The controls and safety features of the reach stacker should also be taken into account. The operator should have easy access to all necessary controls and be able to operate the machine efficiently. Safety features such as retractable spreaders, gantry controls, and rigging systems are crucial for safe container handling operations.

In addition, the reach stacker should have the necessary capabilities for efficient warehouse and storage management. It should be able to handle the stacking and stowage of containers in a timely and organized manner, as well as assist with the picking and packaging of cargo for shipment. The reach stacker should also have the ability to interface with other machinery and systems in the warehouse, such as cranes and forklifts.

In conclusion, choosing the right reach stacker is essential for efficient container handling and logistics operations. Factors such as equipment capabilities, operating capabilities, size and weight, controls and safety features, and warehouse management capabilities should all be taken into consideration when making a decision.

In the field of port and stevedoring operations, the maximum lift capacity is a crucial factor when it comes to container handling and loading. A container handler loader, also known as a reach stacker, is a heavy-duty equipment used in shipping and freight distribution. It is designed to handle and lift containerized goods efficiently and safely.

The reach stacker is equipped with hydraulic controls that allow for precise picking, stacking, and racking of containers. Its maximum lift capacity determines the amount of weight it can handle, making it an essential piece of equipment in the containerization process. The reach stacker’s ability to lift heavy loads is especially critical when it comes to loading and unloading containers from ships.

The container handler loader utilizes electric hydraulics for smooth hoist and rotation movements. Its mobile and retractable spreader enables efficient stowage of containers in the port or warehouse. With its counterbalance and stabilization features, the reach stacker ensures the safe and secure transport and storage of containers.

Automated controls and advanced technology make the container handler loader an indispensable tool in intralogistics and transportation. It streamlines the dispatch, packaging, and handling of containerized shipments. Its maximum lift capacity allows for efficient stacking and storage, optimizing warehouse space and maximizing productivity.

In conclusion, the container handler loader, with its maximum lift capacity, plays a vital role in the efficient and safe handling of containerized goods in shipping and freight operations. It is a key component in the containerization process, enabling the smooth operation of ports, stevedores, and warehousing facilities worldwide.

The Reach Stacker (RST), also known as a container handler loader, is a mobile equipment used in various distribution centers and warehouses for the efficient handling and stacking of containers. Equipped with large tires, a reach mechanism, and a hook or clamp attachment, the RST is capable of hauling and lifting intermodal containers with ease.

In a port or terminal setting, the RST plays a crucial role in loading and unloading containerized cargo onto trucks, wagons, or storage areas. Its heavy-duty construction and controls allow for precise driving and positioning, while the stabilizer and stabilization mechanism ensure safe handling and maneuverability even in challenging conditions.

One of the key features of the RST is its maximum stacking height capability. With its articulated chassis and retractable boom, the RST can reach impressive heights, allowing for efficient utilization of vertical space in warehouses or depots. This vertical stacking capability is essential for optimizing inventory storage and maximizing space efficiency in a warehouse or distribution center.

Additionally, the RST is equipped with a rotating hoist and rigging system, enabling it to handle containers with ease. The container handler’s hoisting and rigging mechanism, combined with its strong transmission and counterbalance, ensure safe and efficient container handling operations, reducing the risk of damage to the cargo or equipment.

In summary, the RST, or container handler loader, is a versatile and efficient machinery for handling, stacking, and packaging containerized cargo. With its maximum stacking height, articulated chassis, and advanced controls, it is an essential tool for the logistics and warehousing industry, aiding in the smooth flow of goods throughout the supply chain.

Maximum stacking height refers to the maximum number of items or containers that can be safely stacked on top of each other without the risk of collapse or damage.

Maximum stacking height is important to prevent accidents and ensure the safety of both workers and the stacked items. Exceeding the maximum stacking height can lead to collapses, falling objects, or damage to the items being stacked.

Maximum stacking height is determined by several factors, including the weight and stability of the items being stacked, the strength of the containers or shelves used, and any regulations or guidelines set by local authorities or industry standards.

Exceeding the maximum stacking height can pose risks such as collapse of the stack, instability and falling objects, which can result in injuries to workers, damage to property, and loss of inventory. It can also increase the risk of accidents during handling and transportation.

To increase maximum stacking height, you can use sturdier containers or shelves that can support heavier loads, implement proper stacking techniques such as interlocking or using supports and dividers, and ensure that the items being stacked are evenly distributed and balanced.