Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

The Rail Mounted Gantry (RMG) and forklift truck have transformed container handling and revolutionized logistics and supply chain operations. These innovative systems have greatly improved efficiency and speed in the transportation and distribution of goods.

With the rise of containerization, the need for efficient handling and transportation of large quantities of goods became paramount. The RMG and forklift truck have become indispensable in the movement and relocation of heavy containers, whether it be loading or unloading from a ship, train, or tanker.

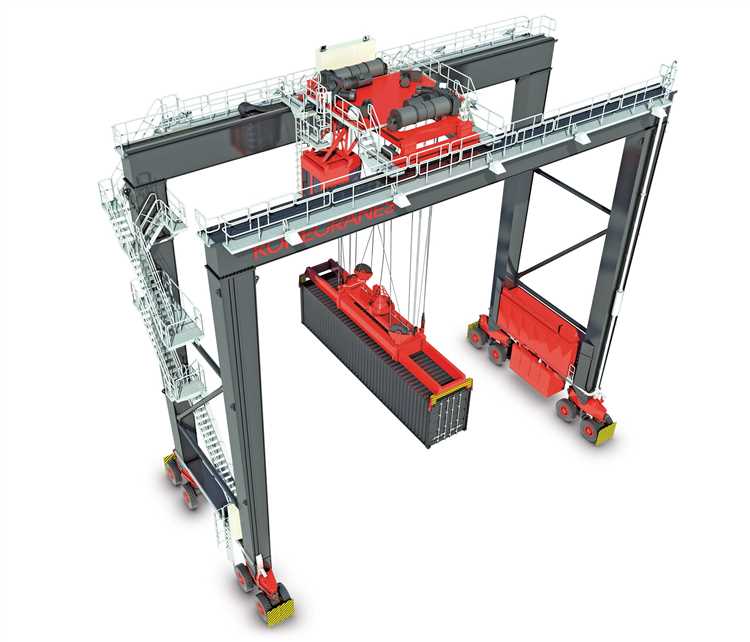

The RMG, a rail-based system, enables the efficient movement and transfer of containers from ship to truck or train, utilizing an intermodal process. Its sophisticated technology and ability to stack and store containers has greatly streamlined operations and reduced handling time. Similarly, the forklift truck has become a key component in material handling equipment, facilitating the loading, unloading, and transportation of containers within warehouses, depots, and yards.

Both the RMG and forklift truck play a crucial role in the efficient movement of containers from point of origin to destination, ensuring timely delivery and replenishment of goods. Their ability to lift, stack, and store containers makes them indispensable in the shipping industry, where the need for efficient logistics and handling is paramount.

When it comes to handling heavy freight in warehousing and dispatch operations, the Rail Mounted Gantry (RMG) and forklift truck play vital roles. These vehicles are specifically designed to efficiently move and transport large quantities of stock and shipments.

The forklift truck, also known as a fork truck or forklift, is a versatile piece of equipment used in various industries. It is primarily used for loading and unloading pallets, replenishment, transfer, and transshipment of materials. Forklift trucks are crucial in distribution and delivery, often seen in trucking and trailer operations, as they can easily lift heavy loads and drive around warehouses, ports, shipyards, and terminals.

On the other hand, the Rail Mounted Gantry (RMG) is a specialized vehicle used in intermodal freight transportation. It is commonly found in rail and port operations, where it plays a crucial role in transferring containers between rail and truck. The RMG operates on rails, using a conveyor system to convey containers from the rail to the storage area or vessel. It maximizes efficiency and minimizes handling time, making it a preferred choice for many railroad depots and ports.

Both the RMG and forklift truck are essential in the handling, scheduling, and inventory management of goods. They ensure the safe and timely relocation, storage, and delivery of freight, whether it’s by rail, truck, or ship. Additionally, these vehicles come in various sizes and capacities, allowing them to handle different types of loads and accommodate the unique requirements of each operation.

In the field of warehousing and transportation, efficient container handling plays a vital role in ensuring smooth operations and timely delivery of goods. One of the key players in this process is the forklift truck, a versatile and powerful piece of material handling equipment.

The forklift truck is mounted with a long, movable arm called a crane, which allows it to reach, lift, and stack containers with precision. This ability to manipulate heavy loads makes it an essential tool in the inventory management and transportation of goods.

When it comes to container handling, forklift trucks are commonly used in ports, intermodal depots, and warehouses. They are used to unload and load containers from trucks, trains, and ships, ensuring a seamless flow of goods and efficient stowage.

With their ability to drive both on the roadway and on tracks, forklift trucks can easily maneuver within the terminal, enabling efficient movement of containers between storage areas and transport vehicles. This flexibility allows for swift and accurate sorting, palletizing, retrieval, and replenishment of containers.

In addition to their mobility, forklift trucks also play a crucial role in ensuring the safety of operations. They are equipped with advanced features such as anti-tip technology and load monitoring systems, which help prevent accidents and damage to containers.

Overall, the forklift truck is a vital tool in modern container handling operations. Its efficient and precise handling capabilities enable the smooth movement and delivery of goods, contributing to the success of the shipping industry as a whole.

Rail Mounted Gantry (RMG) systems and forklift trucks offer several advantages in container handling operations:

Forklift trucks offer numerous advantages when it comes to container handling operations. These versatile vehicles are specifically designed to efficiently transfer goods within a port or terminal, making them an essential part of the material handling equipment used in these facilities.

One of the main advantages of using forklift trucks is their ability to easily lift and move containers. With a hydraulic lifting system and a set of sturdy forks, forklift trucks can effortlessly lift heavy containers and transport them to the desired location. This allows for efficient loading and unloading of containers from various transportation modes, including ships, trains, and trucks.

Another advantage of forklift trucks is their versatility in handling different types of containers. Whether it’s bulk containers, stackable containers, or intermodal containers, forklift trucks can safely handle them all. The adjustable forks and the ability to tilt the mast make it easier to adapt to different container sizes and shapes.

In addition to their adaptability, forklift trucks are also highly maneuverable. Their compact design and precise steering system allow them to navigate through narrow aisles and tight spaces in ports and terminals. This makes them ideal for retrieving and transporting containers from storage areas, stockpiles, and depots.

Furthermore, forklift trucks greatly contribute to the efficient flow of goods and materials within a port or terminal. With their quick loading and unloading capabilities, they can help minimize waiting times for vessels, trucks, and trains. This ensures smooth transit and logistic operations, leading to improved productivity and reduced costs.

Overall, the use of forklift trucks in container handling operations brings multiple benefits. Their efficiency in lifting, transferring, and stacking containers, along with their maneuverability and adaptability, make them essential equipment for ports, terminals, and other logistics facilities. Thanks to forklift trucks, the process of loading, unloading, and delivering containers becomes faster, more organized, and more efficient.

The Rail Mounted Gantry (RMG) and forklift truck are two types of vehicles commonly used in container handling operations. They both serve important roles in the movement and sorting of containers in a terminal or warehouse setting.

The RMG, as its name suggests, is a gantry-mounted system that is typically used in rail or roadway terminals. It is a versatile and powerful machine that can drive along tracks and lift and stack containers with the help of a hoist and carrier system. The RMG offers efficient stacking and sorting capabilities, allowing for fast and organized container movement.

On the other hand, the forklift truck is a movable material handling equipment that is commonly used in warehouses and depots. It has a lifting mechanism that can reach and lift containers, pallets, and other cargo. Forklift trucks are often used for loading and unloading trailers and transporting containers within a yard or warehouse.

When it comes to container handling, the RMG and forklift truck serve different purposes. The RMG is typically used in larger terminals where there is a high volume of containers to be handled. It excels in stacking and sorting containers in a systematic manner, making it ideal for efficient yard management. The forklift truck, on the other hand, is more suitable for smaller-scale operations, such as warehousing and distribution. It is flexible and can navigate tight spaces, making it ideal for loading and unloading containers from trailers and delivering containers to their final destinations.

In terms of efficiency, both the RMG and forklift truck have their advantages. The RMG’s gantry-mounted system allows for efficient stacking and retrieval of containers, minimizing the time it takes to load and unload containers from trucks or ships. It also offers a higher stacking capacity, which enables terminals to store more containers in a limited space. The forklift truck, on the other hand, offers more flexibility in terms of maneuverability and can access containers in tighter spaces. This makes it a preferred choice for operations that require frequent relocation and quick container retrieval.

In conclusion, both the RMG and forklift truck play important roles in container handling operations. The RMG excels in stacking and sorting containers in larger terminals, while the forklift truck is more suitable for smaller-scale operations. Understanding the advantages and applications of each vehicle is essential for efficient container handling and logistics management.

A Rail Mounted Gantry (RMG) system is a type of material handling equipment used in container handling operations at ports and terminals. As the name suggests, the RMG is a gantry crane that is mounted on tracks, providing flexible movement along a designated route. This mobile and movable machinery is designed to efficiently handle the transportation, conveying, and storing of containers.

Operating on a rail track, the RMG utilizes a combination of lift and movement mechanisms to handle containers with ease. Equipped with a powerful fork lift, the RMG can efficiently unload containers from ships and transport them to the terminal or warehouse for storage. The container is securely lifted by the fork and can be easily relocated to the desired location within the depot or along the designated route.

On the other hand, a forklift truck is a versatile vehicle used for loading, unloading, and transporting a variety of materials, including containers. The forklift truck is equipped with forks that can lift and carry heavy loads, making it an essential tool for efficient container handling. With its maneuverability, the forklift truck can navigate through narrow spaces and reach containers stored at various heights in a warehouse or storage facility.

Together, the RMG system and forklift truck revolutionize container handling operations, providing efficient and effective transportation, warehousing, and supply chain management. These material handling tools play a crucial role in the smooth and timely movement of containers, ensuring that goods are delivered to their destination on time.

Whether it’s at a busy port, a bustling warehouse, or aboard a ship, the integration of RMG systems and forklift trucks enables seamless operations and enhances the efficiency of container handling. The combination of these powerful tools improves the overall productivity and reduces the time required for loading, unloading, and transporting containers, ultimately benefiting the shippers, ports, and other stakeholders involved in the logistics industry.

A forklift truck, also known as a lift truck, is a crucial component in the logistics and transportation management system. It plays a significant role in the movement, handling, and transport of containers and other goods in various settings such as warehouses, depots, harbors, and shipyards.

Equipped with a fork-like apparatus, a forklift truck is designed to retrieve, stack, lift, and transport containers efficiently. The main function of a forklift truck is to convey the containers from one location to another, whether it’s from the trailer or railway to the ship or vice versa.

Using hydraulic systems, a forklift truck can hoist and lift containers with ease. It can unload or load containers from ships, stack them in the harbor or stockpile areas, and transport them to the designated areas for further handling or delivery. The forklift truck’s mobility and versatility make it an indispensable tool in the transportation and logistics industry.

Depending on the size and capacity, there are different types of forklift trucks available, including electric, diesel, or gas-powered. Each type has its benefits and specific applications. For example, electric forklifts are suitable for indoor use due to their low noise levels and zero-emission capabilities, while diesel or gas-powered forklifts are better suited for outdoor or heavy-duty operations.

In conclusion, forklift trucks are essential in the smooth operation of container transportation. They provide a reliable and efficient means of transporting, lifting, and stacking containers, allowing for seamless handling and transfer of goods in hubs, shipyards, and logistics facilities.

The Rail Mounted Gantry (RMG) systems play a crucial role in port operations, revolutionizing container handling and improving efficiency. These systems are specifically designed for the efficient movement, stacking, and storage of cargo containers.

One of the main functions of RMG systems is to unload containers from ships and transfer them to the port terminal. Using cranes and mobile forklift trucks, the containers are moved from the shipyard to the quay, where they are sorted and stacked according to their destination.

The RMG systems are mounted on a railway track, allowing them to drive along the entire length of the port terminal. This enables them to efficiently move containers to their designated storage areas or to other modes of transport, such as trucks or trains, for further distribution.

In addition to the movement of containers, RMG systems also play a vital role in inventory management. They provide a means of stockpile and carriage, ensuring that containers are properly stored and easily accessible when needed. This helps optimize the space within the port terminal and allows for efficient packing and replenishment of containers.

Overall, the Rail Mounted Gantry systems have revolutionized the way container handling is done in ports. Their efficient and precise material handling capabilities have significantly improved the logistics and transport processes, making it easier to transfer goods from ships to trucks or trains and vice versa. They have become an essential component in the transportation management system, ensuring the smooth flow of cargo in and out of ports worldwide.

Forklift trucks are another essential piece of material handling equipment in port operations. They are used for a variety of tasks, such as loading and unloading pallets, stock stacking, and transferring goods to and from trucks.

The primary function of forklift trucks in port operations is to efficiently handle palletized goods. They are equipped with forks that can be inserted under pallets for easy lifting and movement. This allows for quick and efficient loading and unloading of goods from trucks and other modes of transport.

In addition to pallet handling, forklift trucks are also used for sorting and organizing goods within the port terminal. They can move goods to designated storage areas, ensuring that inventory is properly managed and easily accessible when needed.

Forklift trucks are especially crucial for the transport and handling of heavy goods in ports, such as containers or tankers. Their ability to reach high stack heights and their strong lifting capacities make them ideal for these tasks.

In summary, forklift trucks play a vital role in port operations, facilitating the efficient movement and handling of goods. They are an essential tool in the logistics and cargo handling processes, helping to improve efficiency and productivity in ports worldwide.

Forklift trucks play a crucial role in the efficient and timely handling of cargo in port operations. These mobile vehicles are designed to haul, reach, and dispatch containers to and from various areas of the port, including the quay and warehousing facilities.

One of the primary functions of forklift trucks is the loading and unloading of containers from vessels. They can efficiently maneuver between the rows of containers on the yard, using their fork attachments to lift and stack containers safely and securely. This allows for easy transportation of goods from the vessel to the container yard and vice versa.

In addition to loading and unloading, forklift trucks are also used for sorting, packing, and storing containers in the port. They play a vital role in the inventory and material handling aspect of port operations, ensuring that goods are properly organized and ready for transportation.

Forklift trucks are equipped with powerful engines and hydraulic systems, allowing them to lift heavy loads and maneuver in tight spaces. They are an essential piece of equipment in the intermodal transportation system, facilitating the movement of containers from the port to other modes of transportation, such as trains or trailers.

Overall, forklift trucks are a key component in the efficient and safe handling of cargo in port operations. Their ability to load, unload, stack, and transport containers makes them invaluable in the movement and storage of goods throughout the port terminal.

Container handling in logistics operations presents various challenges, especially when it comes to the efficient movement and handling of cargo in harbors and terminals. One of the key challenges is the need for reliable and versatile equipment to perform the tasks involved in containerization, including loading, unloading, palletizing, and retrieval.

In this context, forklift trucks have proven to be crucial assets in container handling operations. These vehicles, also known as forklifts or lift trucks, are specially designed to lift and transport containers or other heavy loads. They are equipped with forks that can be inserted under the container, allowing for easy carriage and movement.

One of the main challenges in forklift truck operations is the need for precise maneuvering and positioning. When working in tight spaces, such as terminals or warehouse areas, forklift truck operators must navigate through aisles, stack containers, and accurately unload or load them onto trailers or railroad cars. The ability to convey containers safely and efficiently is essential to avoid accidents and optimize the flow of goods.

Furthermore, forklift trucks must be capable of handling various container sizes and weights. Containers come in different dimensions and can carry a range of cargoes, including bulk or packaged goods. Therefore, forklifts need to be adaptable to accommodate these variations and ensure the safe transportation of containers without causing any damage.

Another challenge related to forklift truck operations is the need for maintenance and repair. These vehicles undergo intensive use and are subject to wear and tear, which can result in mechanical failures. Regular maintenance is necessary to keep the forklifts in optimal condition and avoid downtime in container handling operations.

In conclusion, forklift trucks play a crucial role in addressing the challenges faced in container handling. They provide the necessary equipment to efficiently move, lift, and transport containers, ensuring the smooth flow of goods in logistics operations. By overcoming these challenges, forklift trucks contribute to the overall success of container handling operations, improving efficiency, and reducing costs.

Rail Mounted Gantry (RMG) and forklift trucks have revolutionized container handling operations in the logistics industry. These systems have addressed numerous challenges in the efficient retrieval, storage, and distribution of containers in ports, harbors, and warehouses.

RMG systems are specially designed cranes that are mounted on rails, allowing them to travel along designated tracks. These cranes are capable of lifting and moving containers, making them essential in container handling operations.

One of the challenges that RMG systems address is the efficient retrieval of containers from ships, docks, and warehouses. These systems can carefully lift and transport containers from one location to another, ensuring smooth and timely logistics operations.

Additionally, RMG systems have also improved the stacking and storing of containers in storage yards and depots. With their precise lifting capabilities, these systems can stack containers neatly, optimizing space and enabling efficient inventory management.

Forklift trucks, also known as forklifts, are versatile and mobile material handling equipment commonly used in various industries. In container handling operations, forklift trucks play a crucial role in moving containers within warehouses and storage yards.

These trucks are equipped with fork-like attachments that can easily lift and transport containers. They are essential in sorting and organizing containers based on their destination, ensuring efficient distribution and transit of goods.

Forklift trucks are also used in the unloading and loading of containers from trucks and ships. Their maneuverability allows for easy access to containers, facilitating swift and smooth operations in ports and shipyards.

Furthermore, forklift trucks can be utilized in intermodal transportation, as they can easily transfer containers between trucks, trains, and warehouses. This flexibility in operation makes them an invaluable tool in the distribution and logistics industry.

In conclusion, Rail Mounted Gantry (RMG) systems and forklift trucks address various challenges encountered in container handling operations. These equipment and machines streamline the retrieval, storage, and distribution of containers, ensuring efficient and timely logistics across ports, warehouses, and transport hubs.

Forklift trucks play a crucial role in the logistic operation of container handling, addressing various challenges associated with the movement, loading, unloading, and storage of cargo. These versatile vehicles are specifically designed to efficiently handle and transport heavy materials, palletized goods, and containers.

One of the major challenges that forklifts trucks address is the replenishment and stockpiling of containers. With their mobility and lifting capabilities, forklift trucks can easily stack and retrieve containers from various locations in the warehouse or port terminal. This makes it easier to maintain an organized stock and ensure efficient containerization for transportation and shipping.

In addition to container handling, forklift trucks are also utilized for palletizing and storing goods. By using forklifts equipped with specialized attachments such as conveyor belts or hoists, it becomes easier to unload and load goods onto trucks or trains. This streamlines the entire process of transferring and relocating cargo, improving the overall efficiency of the logistics and distribution operations.

Furthermore, forklift trucks are essential in the retrieval and transfer of containers from one location to another. Whether it is from a ship to a truck, or from the warehouse to a carriage, forklift trucks enable the smooth movement of containers, eliminating delays and minimizing the possibility of damage to the cargo.

In conclusion, forklift trucks are indispensable in the world of logistics and warehousing. They provide efficient and reliable solutions to the challenges associated with container handling, stock management, and transport. With their ability to lift and transport heavy loads, forklift trucks play a vital role in ensuring the smooth delivery and distribution of goods, improving overall operational efficiency.

When it comes to efficient haulage and movement of containers in a port or warehouse, the use of Rail Mounted Gantry (RMG) systems and forklift trucks has proven to be a game-changer. These material handling equipment have revolutionized container handling operations, making them faster, safer, and more cost-effective.

One successful case study involves the use of RMG systems in an intermodal terminal. These systems, mounted on a track, are capable of storing and stacking containers with ease. By efficiently moving containers from the port to the warehouse, RMG systems have significantly reduced the time taken to load and unload ships, improving the overall operations of the terminal.

In another case study, forklift trucks have played a crucial role in the smooth handling of cargo in a busy port. These mobile equipment allow for the efficient movement of containers, pallets, and packages from one location to another. By using forklift trucks, the port has been able to effectively manage its inventory and ensure timely delivery of goods to shippers and customers.

Both RMG systems and forklift trucks have also proven to be essential in warehouse operations. RMG systems provide a reliable and space-saving solution for storing and stacking containers, while forklift trucks are used for the internal movement of materials within the warehousing facility. These equipment have enabled warehouses to enhance their supply chain management, streamline their inventory, and improve the overall efficiency of their operations.

Overall, the success stories of RMG systems and forklift trucks in container handling demonstrate the significant impact these equipment have had on the transportation and logistics industry. Whether in a port, intermodal terminal, or warehouse, these material handling equipment have revolutionized the way containers are stored, moved, and delivered, making the entire journey from shipload to carriage more efficient and cost-effective.

With the constant advancements in technology and continuous improvements in these systems and equipment, the future of container handling looks promising for both the shipping industry and the efficient movement of goods worldwide.

Forklift trucks have revolutionized container handling in various industries, proving to be highly efficient and reliable. Let’s take a look at some success stories where forklift trucks have played a significant role:

At a busy port terminal, forklift trucks are indispensable when it comes to loading and unloading containers from ships. The trucks skillfully navigate the roadways within the terminal, carefully stack and transport containers to their designated areas. With their precise route planning, the forklift trucks efficiently handle the containerization process, saving time and ensuring smooth operations at the port.

In a large warehouse facility, forklift trucks are widely used for inventory management and storing goods. These trucks have the ability to swiftly drive through narrow aisles, reaching high shelves to pick up and move heavy pallets. The forklift trucks effectively convey the goods to their designated locations, optimizing the storage space and ensuring easy access for replenishment and shipment.

A logistics company relies on forklift trucks for the transportation of goods from the warehouse to the delivery vehicles. The trucks efficiently load and unload the cargo, using their lifting and hoisting equipment. With their strong gantry systems, forklift trucks can handle a wide range of loads, including containers, pallets, and even luxury yachts. They ensure the smooth flow of goods from the warehouse to the carrier, enhancing the overall transportation process.

In a manufacturing plant, forklift trucks play a crucial role in the handling of raw materials and finished products. These trucks are used in conjunction with conveyor systems to convey the stock from one area to another. With their precision in loading and unloading, forklift trucks help streamline the production process, ensuring that materials are readily available for assembly and timely delivery to customers.

Overall, these case studies demonstrate how forklift trucks have revolutionized container handling across various industries, from port terminals, warehousing, logistics, and manufacturing. Their versatility, efficiency, and reliability make them an essential equipment in the transportation and handling of goods.

Rail Mounted Gantry (RMG) and forklift truck technologies are revolutionizing container handling in the transportation and logistics industry. These two innovative technologies provide efficient and seamless processes for loading, unloading, and transporting containers.

The integration of RMG and forklift truck technologies allows for smooth and efficient handling of containers in various operations, including warehouse and harbor operations. The RMG is a movable gantry crane that runs on tracks, enabling it to retrieve and convey containers in a controlled and precise manner. On the other hand, forklift trucks are versatile and mobile vehicles equipped with a fork that can lift and transfer containers.

By combining these two technologies, container handling becomes even more efficient. The RMG can retrieve containers from ships and store them in a designated area or directly load them onto trailer or truck for further transportation. The forklift truck can then transport these containers to the desired location, whether it is a warehouse, depo, or roadway.

The integration of RMG and forklift truck technologies streamlines the container handling process, reducing the time and effort required for loading and unloading. This translates to faster transportation and delivery, improving the overall efficiency of logistics operations. The ability to handle containers seamlessly between different modes of transportation, such as ships, trucks, and trains, allows for smoother intermodal transportation.

Furthermore, this integration enables efficient containerization, ensuring that goods are securely stored and transported. Containers can be easily stacked and stored, maximizing space utilization and reducing the risk of damage during transportation. The integration of RMG and forklift truck technologies also improves the accuracy of container retrieval and storage, minimizing errors and delays in the distribution schedule.

In conclusion, the integration of Rail Mounted Gantry (RMG) and forklift truck technologies is paving the way for the future of container handling. These technologies offer efficient, mobile, and versatile solutions for the transportation and logistics industry, revolutionizing the way goods are loaded, transported, and delivered. With the integration of RMG and forklift truck technologies, container handling becomes faster, more reliable, and more efficient.

The future of container handling is moving towards integration of Rail Mounted Gantry (RMG) and forklift truck technologies.

Rail Mounted Gantry (RMG) technology refers to the use of large, gantry-style cranes that run on rails to lift and move containers at ports and container terminals.

Integrating RMG and forklift truck technologies can improve efficiency, increase throughput, and reduce operational costs in container handling operations.

By combining the lifting capacity of RMG cranes with the maneuverability and flexibility of forklift trucks, container handling operations can be streamlined and containers can be moved more quickly and efficiently.

Potential challenges in integrating RMG and forklift truck technologies include adapting existing infrastructure, coordinating movements between different types of equipment, and training operators on new systems.