Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

Rubber-Tired Gantry Cranes, also known as RTGs, are essential equipment in the shipping industry. These cranes are designed to efficiently and effectively handle containerized freight at ports and terminals. With their innovative design and rubberized tires, RTGs can easily navigate the port facility, maneuvering around obstacles and guiding containers to their destinations.

RTGs are equipped with heavy-duty wheels that allow them to travel over various surfaces, such as concrete, asphalt, and railway tracks. This flexibility makes them ideal for port operations, as they can easily switch between different modes of transportation. Additionally, RTGs are liftable, meaning they can be elevated to reach containers stacked several rows high, making them indispensable in efficient container handling.

One of the key advantages of RTGs is their ability to be operated electrically. This not only reduces emissions and environmental impact but also improves safety for workers on the ground. RTGs are also automated, which means they can be programmed to perform precise movements, making them highly efficient in container handling operations.

When it comes to moving containers, RTGs are a cost-effective solution. They can lift and transport containers from ships to port facilities, as well as from port to truck or rail, eliminating the need for additional equipment such as forklifts or conveyors. This streamlines the entire shipment process and reduces handling time and costs.

Overall, Rubber-Tired Gantry Cranes are an essential piece of equipment in the shipping and logistics industry. Their ability to handle containerized freight efficiently, maneuver around various surfaces, and automate operations makes them a vital asset in any port or terminal facility. With their innovative design and flexible capabilities, RTGs continue to revolutionize the way goods are handled and transported, ensuring the smooth flow of global trade.

A rubber-tired gantry crane, also known as an RTG crane, is a heavy-duty crane used in terminalization and cargo handling operations. It is designed to mobilize and lift heavy loads, making it an essential piece of equipment in the shipping and logistics industry.

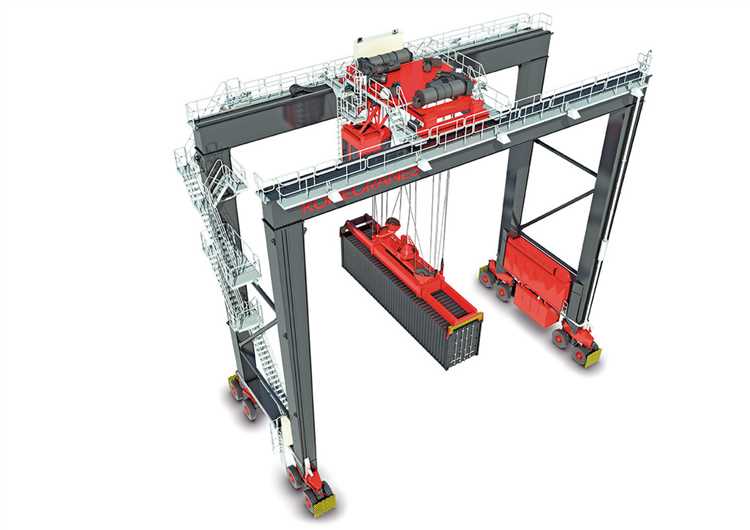

The main components of a rubber-tired gantry crane include a chassis, a portal crane, and a motorized platform with wheels. The chassis serves as the base of the crane and provides stability and support. The portal crane, mounted on top of the chassis, is responsible for lifting and maneuvering the heavy loads. The motorized platform with wheels allows the crane to move and drive on various surfaces, such as roads, railroads, and trailer platforms.

One of the key features of a rubber-tired gantry crane is its efficient maneuverability. The crane is equipped with steering and guidance systems that allow it to rotate, steer, and drive in different directions. This innovative design enables the crane to work effectively in tight spaces and navigate around obstacles, making it ideal for use in congested industrial facilities and shipping terminals.

The lifting capacity of a rubber-tired gantry crane is impressive, with some models capable of lifting loads up to several hundred tons. The crane utilizes a hoist and a system of ropes and chains to secure and lift the cargo. This reliable lifting mechanism ensures safe and efficient handling of heavy loads.

In addition to its lifting capabilities, a rubber-tired gantry crane also offers convenient storage and maintenance features. The telescopic axle and the motorized platform allow for easy positioning and storage of the crane when not in use. The crane’s design also includes a spacious operator cabin for comfortable and ergonomic control. Regular maintenance of the crane is facilitated by easy access to key components and a well-designed maintenance platform.

In conclusion, a rubber-tired gantry crane is a versatile and efficient machine used in various industries, including warehousing, shipping, and logistics. Its heavy-duty construction, innovative steering and guiding systems, and reliable lifting capabilities make it an indispensable tool for handling and maneuvering heavy loads in industrial facilities and shipping terminals.

A rubber-tired gantry crane is a versatile and movable machine that is commonly used in ports and terminals for loading and unloading shipments. It is a type of crane that relies on rubber tires instead of tracks, making it more flexible and cost-effective. The crane is equipped with a rigid gantry structure that carries the main hoist and lifting system.

When a ship or truck arrives at the terminal, the rubber-tired gantry crane travels along the dock to where the shipment is located. The crane is designed to be highly productive and efficient in handling heavy loads, such as containers and pallets. Its rubber-tired wheels enable it to maneuver easily on various surfaces, including the dock floor, railway tracks, and even automated terminals.

One of the key features of a rubber-tired gantry crane is its ability to rotate. This allows the crane to change its direction and align with the shipment, ensuring safe and precise maneuverability. The crane’s steering and braking systems ensure stability and safety during operation.

Using its liftable and stable rubber-tired wheels, the crane can easily pick up and transport containers and other intermodal units. Its electric and hydraulic systems provide the necessary power to lift and move heavy loads efficiently. This makes the rubber-tired gantry crane an essential tool in the logistics and shipping industry, enabling quick and efficient stowage and retrieval of cargo.

Overall, the rubber-tired gantry crane is a highly efficient and cost-effective machine for handling shipments in terminals and ports. Its flexibility, maneuverability, and rotational abilities make it a crucial asset in the logistics supply chain. Whether it is unloading ships, moving heavy loads, or navigating through automated terminals, the rubber-tired gantry crane is an indispensable tool in the shipping industry.

Rubber-tired gantry cranes (RTGs) offer numerous advantages for efficient and cost-effective handling of containers and other heavy loads in various industries.

Rubber-Tired Gantry (RTG) cranes are widely used in various applications due to their versatility and efficiency. These cranes are equipped with rubber tyres, which enable them to travel and maneuver easily on different surfaces.

One of the key applications of RTG cranes is in container terminals. These cranes are used for hoisting and moving containers from one location to another within the terminal. The rotating and hoisting abilities of the crane, combined with the rigid and steerable chassis, make it an effective tool for container handling.

Another application of RTG cranes is in intermodal yards, where containers need to be transferred between different modes of transportation, such as trucks, railways, and ships. These cranes can stack and unstack containers, allowing for efficient container transfer.

In addition, RTG cranes are used in logistics and warehousing facilities. They can be used for truckload shipments, where containers are loaded and unloaded from trucks. The rubber-tired gantry crane’s ability to travel and maneuver on different surfaces makes it suitable for these operations.

The maintenance of RTG cranes is also a crucial application. These cranes require regular maintenance to ensure optimal performance and longevity. Routine inspections, lubrication, and repair are carried out to keep the cranes in good working condition.

In summary, rubber-tired gantry cranes have a wide range of applications, from container terminals to intermodal yards and logistics facilities. Their innovative design, which includes rubber tyres and a steerable chassis, allows for efficient and effective movement and transfer of containers. These cranes play a vital role in the transportation and terminalization of containerized goods, making them an essential tool in various industries.

A rubber-tired gantry crane, also known as an RTG crane, is a heavy-duty machine used in industrial terminals and shipyards for the efficient handling of containers. This type of crane consists of several key components that work together to facilitate the loading, unloading, and transportation of containers.

The rubber-tired gantry crane is an essential tool in the logistics and shipping industry. With its reliable and efficient design, it enables the smooth and safe transportation of containers in a fast-paced and constantly changing environment. Whether in an industrial terminal or shipyard, this crane plays a crucial role in the containerization and movement of goods.

When it comes to safety, rubber-tired gantry cranes (RTGs) are equipped with several features to ensure a secure working environment. One key safety feature is the crane’s stability, which is maintained through the use of outriggers and a strong wheel platform. These components provide a solid foundation for the crane, allowing it to safely maneuver and lift heavy loads without the risk of tipping over.

Another important safety feature is the use of remote control technology. This allows operators to control the crane from a safe distance, reducing the risk of accidents or injuries. The remote control system also provides the operator with a clear view of the working area, ensuring safe and efficient operation.

The rubber-tired gantry crane is also equipped with safety devices such as brakes and limit switches. The brakes are designed to stop the crane’s movement quickly and effectively in case of emergency, while the limit switches prevent the crane from overstepping its predefined boundaries. These features minimize the risk of collisions and accidents during operation.

In addition, RTGs are designed with specialized equipment for safe container handling. This includes conveyor systems for efficient unloading and loading of containers, as well as containerized lifts for secure transport. These features ensure the safe and efficient movement of containers in shipyards, harbors, and other intermodal facilities.

The rubber-tired gantry cranes also prioritize safety during the transportation and stacking of cargo. Their versatile and cost-effective design allows for efficient stacking of containers in storage yards and loading onto trucks or railroad cars. The cranes use rubberized tires to prevent floor hazard, while their strong wheels and efficient steering systems ensure smooth maneuvering and precise positioning of containers.

In conclusion, the safety features of rubber-tired gantry cranes make them an efficient and secure choice for material handling and shipment. Whether it’s in a shipyard, harbor, or intermodal facility, the safety mechanisms integrated into these cranes provide a reliable and safe solution for the storage, loading, and transport of containers, ensuring the smooth flow of goods in the global shipping industry.

When choosing a rubber-tired gantry crane for your cargo handling needs, there are several factors that you should consider to ensure the optimal performance and efficiency of the crane.

One of the main factors to consider is the type of cargo that will be handled by the crane. Different rubber-tired gantry cranes are designed to handle specific types of cargo, such as containers, pallets, or bulk freight. It is important to choose a crane that is specifically designed for the type of cargo you will be handling to ensure safe and efficient operation.

The area in which the crane will be operating is another important factor to consider. The size and layout of the space will determine the maneuverability and lifting capacity required for the crane. Additionally, if the area is prone to changing weather conditions or uneven terrain, it is essential to choose a crane that can handle these challenges with stability and control.

The guiding system of the rubber-tired gantry crane determines how it navigates and positions itself within the operating area. There are different guiding systems available, such as rail-guided or electric-powered systems, each with its own advantages and suitability for specific applications. Choosing the right guiding system will ensure accurate and efficient movement of the crane.

Consider whether you require a fully automated rubber-tired gantry crane or if manual control is sufficient for your operations. Automation can greatly improve efficiency and reduce the need for human intervention, especially in terminalization and storage facilities. However, it may require a more complex control system and additional maintenance.

The maintenance requirements of the rubber-tired gantry crane should also be taken into account. Consider factors such as the accessibility of different parts for maintenance, the lifespan of the tyres, and the availability of spare parts. Additionally, check if the crane has liftable parts, such as a liftable axle or platform, which can provide flexibility in certain operations.

In summary, when choosing a rubber-tired gantry crane, consider the type of cargo, area of operation, guiding system, automation and control, and maintenance requirements. Taking these factors into account will help you select a crane that is versatile, efficient, and perfectly suited to your specific needs in cargo handling and freight operations.

Rubber-tired gantry cranes, also known as RTGs, are widely used in various industries and terminals for efficient handling and transportation of containers. To ensure their reliable operation and safety, regular maintenance and inspection of these cranes is crucial.

One important aspect of maintenance is checking the condition of the tires. RTGs are equipped with rubberized tires that provide excellent traction and enable smooth maneuvering on various surfaces. Regular inspections of the tires, including checking the tire pressure, tire wear, and any signs of damage or punctures, are essential to ensure safe and effective crane operation.

Another important component to consider is the hydraulic system. RTGs rely on hydraulic power for various functions such as lifting and lowering containers, moving the gantry along the yard, and extending the outreach. Regular inspection of the hydraulic system, including checking for any leaks, ensuring proper lubrication, and inspecting hydraulic hoses and fittings, is essential to prevent any potential failures and maintain optimal crane performance.

Furthermore, the electrical systems and controls of RTGs should be regularly inspected to ensure their proper functioning. This includes checking for any loose connections, inspecting the control panels and switches, and testing the emergency stop system. Regular maintenance and testing of the electrical systems are necessary to prevent any malfunctions that could pose hazards to operators and the equipment itself.

In addition to these specific components, regular maintenance tasks such as checking and tightening bolts and clamps, inspecting the gantry structure for any signs of corrosion or fatigue, and greasing the moving parts should be performed. These maintenance activities help prolong the lifespan of the crane and ensure its continuous and safe operation.

Overall, the maintenance and inspection of rubber-tired gantry cranes are essential for their reliable and safe operation. By regularly checking and maintaining the tires, hydraulic system, electrical systems, and other components, operators can ensure the optimal performance of the cranes and minimize the risk of accidents or failures. Following a comprehensive maintenance schedule and conducting regular inspections are key to preserving the longevity and efficiency of these versatile and innovative machines.

Rubber-tired gantry (RTG) cranes are versatile and essential tools in various industries, including shipping, logistics, and warehousing. However, like any equipment, they can encounter issues that require troubleshooting to ensure smooth operations.

One common issue with RTG cranes is the changing nature of the gantry itself. As these cranes are motorized and operated by a driver, they need to be able to navigate various terrains and surfaces. This can sometimes lead to challenges in maneuvering and stability, especially when encountering uneven floors or obstacles.

Another common issue is related to the rubberized tyres of the gantry. These tyres are designed to provide traction and flexibility for the crane, enabling it to handle heavy loads and transport cargo efficiently. However, they can wear down over time due to constant use, requiring replacement or repair to maintain optimum performance.

The handling of containers is a critical aspect of gantry crane operation, and issues can arise in this area as well. Due to the rigid nature of the containers, there may be challenges in stacking and organizing them in a safe and efficient manner. Ensuring proper rotation and placement of the containers can help to mitigate these issues.

Furthermore, automation and remote control systems are increasingly being integrated into RTG cranes. While these technological advancements enhance efficiency and precision, they can also present challenges in terms of system calibration and troubleshooting. It is vital to have a robust maintenance and support system in place to address any technical issues promptly.

In summary, common issues with rubber-tired gantry cranes include challenges in navigating various terrains, wear and tear of the gantry’s rubberized tyres, difficulties in container handling, and technical issues related to automation and remote control systems. By addressing these issues promptly and effectively through troubleshooting and regular maintenance, RTG cranes can continue to be reliable and cost-effective tools for handling and transporting cargo in industries such as shipping, logistics, and warehousing.

When it comes to the cost of rubber-tired gantry cranes (RTGs), there are several factors that can influence the overall price. One of the main factors is the size and capacity of the crane. Larger and heavier-duty RTGs typically have a higher cost due to the more robust construction and components required.

Another factor that can affect the cost is the level of automation and advanced features. Some RTGs are equipped with remote control systems and automated steering, which can increase the price. These features offer improved maneuverability and efficiency, making them ideal for busy logistics and shipyard terminals.

The type of drive system can also impact the cost of an RTG. There are two main options: electric and diesel. Electric RTGs are popular due to their environmental friendliness and lower operating costs, but they may have a higher initial investment. Diesel-powered RTGs are more common in areas where electricity supply is limited or where the cost of electricity is high.

The design of the rubber tires used on the gantry crane is another aspect that can affect the cost. Pneumatic tires are more versatile and can be used on various surfaces, including rough terrain and paved roads. Rubberized tires are specifically designed for terminality and quay surfaces and provide better traction, but they may increase the cost of the crane.

Overall, while the initial investment in an RTG can be significant, it is often a cost-effective solution for many transportation and logistics companies. The versatility and maneuverability of RTGs make them an excellent choice for loading and unloading containers from trucks, trailers, and forklifts. They can be easily maneuvered in tight spaces and offer efficient stacking and transferring of heavy loads. Whether used in a port, shipyard, or a stockyard, RTGs provide a reliable and efficient solution for handling containers and improving the overall logistic operations.

As the demand for efficient and effective material handling equipment continues to grow, the rubber-tired gantry crane (RTG) has emerged as a popular choice for many industries. Leading manufacturers have developed innovative designs and technologies to meet the diverse needs of port terminals, construction sites, and stockyards.

The RTG, also known as a gantry crane or yard crane, is equipped with rubber tires that allow for easy maneuvering and navigation across various terrains. Instead of using ropes, the RTG utilizes a powerful hoisting system that is capable of lifting heavy containers and other materials with ease.

Some of the top manufacturers of rubber-tired gantry cranes include companies like Konecranes, Liebherr, and ZPMC. These industry leaders offer a range of models, each with different features and capabilities to suit specific applications.

One of the key components of a rubber-tired gantry crane is the steering axle. This axle allows the crane to mobilize and change direction smoothly. In addition, the RTG is equipped with clamps or forks that can be used for stacking and handling containers, as well as other materials such as pallets or heavy machinery.

Another important feature of these cranes is the rubberized wheel pads and brakes, which ensure stability and safety during operation. The rubberized pads provide traction and reduce the risk of slippage, especially when working on slippery surfaces like quays or harbor areas. The brakes, on the other hand, allow for precise stopping and positioning of the crane.

In terms of power source, RTGs can be either electric or pneumatic. Electric RTGs are more commonly used in port terminals and offer better efficiency and lower operating costs. Pneumatic RTGs, on the other hand, are often preferred for heavy-duty construction or transportation applications.

Overall, the rubber-tired gantry crane is a cost-effective and flexible solution for various material handling tasks. Its ability to navigate through narrow spaces and its power to lift heavy loads make it a valuable asset in industries that rely on efficient and safe transportation and stacking of goods.

Tire technology is constantly advancing, and this extends to the engineering of rubber-tired gantry cranes (RTGs). The future of RTG technology lies in the continued development of tires and wheels that can work more efficiently on various surfaces, such as terminal yards and shipping docks. These innovative tires will be designed to withstand heavy loads and maximize traction, allowing the RTGs to operate effectively in any environment.

One potential future trend is the terminalization of RTGs. This involves creating a dedicated area within a shipping terminal where the RTGs can unload and load containers directly from ships. By eliminating the need for truckload operations, this terminalization process can streamline the supply chain and reduce costs.

Another trend in RTG technology is the development of motorized RTGs. These machines use a motorized wheel to straddle the container or trailer, allowing for more flexible and efficient operation. Motorized RTGs offer improved maneuverability and can rotate on their axis, making them versatile in tight spaces.

Furthermore, the use of pneumatic tires and hydraulic systems is expected to increase in RTG technology. Pneumatic tires provide better load distribution and shock absorption, while hydraulic systems enable smoother and more precise movements. These advancements will contribute to the overall efficiency and effectiveness of RTGs.

The future of RTG technology also includes the use of conveyor systems to load and unload containers. Instead of relying on manual labor or cranes, conveyor systems allow for more automated and faster container handling. This can save time and improve productivity in busy shipping terminals.

Lastly, advancements in guiding systems are being made to improve the reach and rotation of RTGs. These systems use rope or chain mechanisms to securely guide the RTGs along a set path, ensuring precise movement and minimizing the risk of accidents. With improved guiding systems, RTGs can efficiently navigate the terminal and handle containers with ease.

In conclusion, the future of rubber-tired gantry crane technology is focused on developing more cost-effective and efficient machines. With advancements in tire and wheel technology, terminalization processes, motorization, pneumatic and hydraulic systems, and guiding systems, RTGs will become even more versatile and capable of handling the demanding operations of shipping terminals and intermodal logistics.

Future trends in rubber-tired gantry crane technology include the incorporation of advanced automation and artificial intelligence systems, increased energy efficiency through the use of electric or hybrid power sources, improved safety features, and the development of more durable and lightweight materials for construction.

Advanced automation and artificial intelligence systems will enable rubber-tired gantry cranes to operate more efficiently and autonomously. These systems can optimize crane movements, reduce human error, and enable remote control and monitoring of operations.

Using electric or hybrid power sources in rubber-tired gantry cranes can lead to increased energy efficiency and reduced emissions. These power sources can also help reduce operating costs and reliance on fossil fuels.

Safety features in rubber-tired gantry cranes will continue to improve through the incorporation of advanced sensors, cameras, and collision detection systems. These features will help prevent accidents, improve operator visibility, and enable real-time monitoring of crane operations.

Developing more durable and lightweight materials for rubber-tired gantry cranes can lead to increased lifting capacities, improved fuel efficiency, and reduced maintenance costs. These materials can also increase the lifespan of cranes and reduce their environmental impact.

The future trends in rubber-tired gantry crane technology will have a significant impact on port operations. By increasing automation, improving safety, and reducing energy consumption, these technologies will help ports become more efficient, reduce delays, and handle larger volumes of cargo.