Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

In today’s fast-paced business environment, effective yard management and yard flow strategies are essential for maximizing efficiency. Dispatching and organizing yard operations efficiently is crucial for optimizing yard utilization and capacity. Yard maintenance plays a key role in ensuring the smooth flow of yard traffic and reducing disruptions. To achieve these goals, companies can leverage yard software and yard technology to automate yard processes and enhance yard performance.

A well-designed yard layout and dock management system are vital for streamlining the handling and storage of goods, particularly in a freight yard. Just-in-time scheduling and expedited yard system routing can help organizations expedite yard processing and supply chain activities. Yard security systems and yard inspections are essential for maintaining the security and integrity of yard assets.

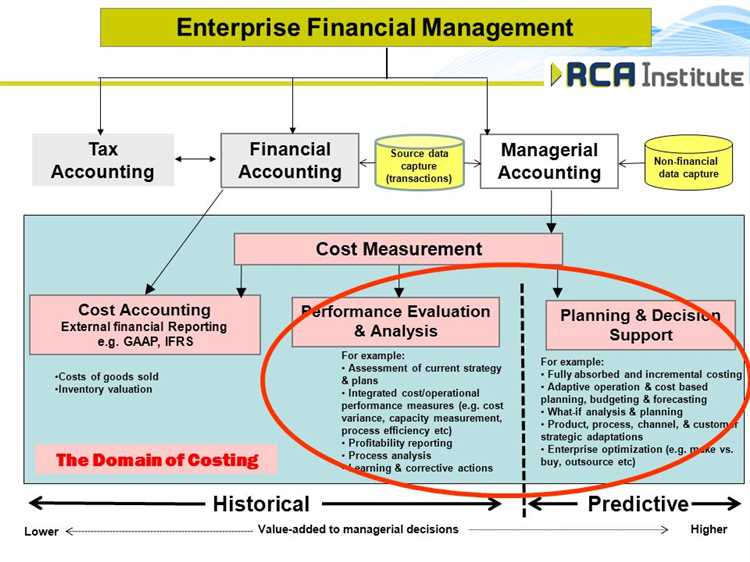

Yard management software provides real-time visibility and control over yard resources, allowing companies to optimize yard performance and make informed decisions. Dock control and yard spread optimization ensure that yard capacity is efficiently utilized, reducing congestion and delays. Efficient yard processing and maintenance enable faster turnaround times and enhance overall operational efficiency.

By implementing effective yard management and yard flow strategies, companies can reduce costs, minimize idle time, maximize productivity, and improve customer service. Streamlining yard operations through automation, optimization, and effective scheduling can help organizations gain a competitive edge in today’s dynamic business landscape.

Efficient yard management and yard flow strategies offer a multitude of benefits for organizations involved in yard handling and trailer movement. By optimizing the process of unloading and managing yard inbound and outbound activities, companies can maximize their operations’ efficiency and throughput.

One key benefit of efficient yard management and yard flow is improved yard space utilization. By effectively allocating yard spread and properly managing yard inventory, companies can make the most of their available yard space and minimize bottlenecks. This helps optimize routing and processing of containers and trailers, ensuring smoother operations and reducing delays.

Another advantage of efficient yard management is enhanced yard visibility. By utilizing yard software and conducting regular yard inspections, companies can gain better visibility into their yard operations, allowing them to make informed decisions and improve overall yard control. This visibility also enables accurate yard planning and scheduling, further streamlining operations and reducing costs.

Efficient yard management and yard flow strategies also contribute to improved dock management. By expediting yard truck movement and coordinating dock control activities, companies can minimize waiting times and maximize the utilization of dock resources. This leads to faster turnaround times, increased productivity, and improved customer satisfaction.

Furthermore, efficient yard management helps optimize yard processing and order management. By implementing effective yard control measures and employing advanced yard software, organizations can streamline their order processing, reduce errors, and improve overall supply chain efficiency. This, in turn, enables faster dispatching, timely deliveries, and better inventory management.

Overall, investing in efficient yard management and yard flow strategies brings numerous benefits to organizations, including increased yard efficiency, optimized operations, improved throughput, and enhanced customer satisfaction. By focusing on yard planning, shunting, maintenance, and storage, companies can drive productivity and achieve greater efficiency in their yard handling and storage activities.

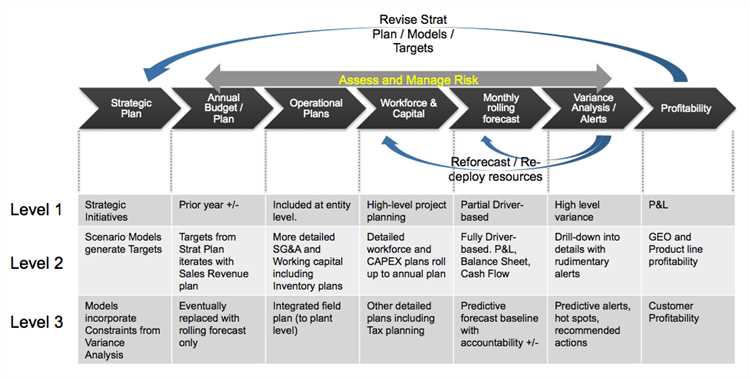

Yard flow is an essential aspect of efficient yard management and can greatly impact overall yard performance. To effectively manage yard flow, organizations often rely on yard management software or yard tracking systems. These software systems enable real-time visibility into yard inventory and help streamline yard processing and operations.

With proper yard flow management, organizations can optimize their yard handling and minimize yard spread. By strategically planning yard design and implementing efficient yard spread, organizations can ensure that containers and inventory are stored in a way that maximizes accessibility and minimizes unnecessary movement.

Yard flow management also plays a crucial role in dock control and order management. By effectively tracking and coordinating yard movement, organizations can ensure that containers are received and dispatched in a timely manner, optimizing the overall supply chain and enabling just-in-time delivery.

Yard flow metrics are important tools in managing and improving yard performance. By regularly analyzing yard metrics, such as yard utilization and turn times, organizations can identify areas for improvement and implement strategies to enhance yard efficiency.

In conclusion, understanding and effectively managing yard flow is crucial for maximizing efficiency in yard management and optimizing overall operational performance. By utilizing yard tracking systems, implementing effective yard flow strategies, and regularly analyzing yard metrics, organizations can streamline yard operations, improve inventory control, and enhance the overall efficiency of their supply chain.

Yard management plays a crucial role in organizing yard operations and maximizing efficiency in the transportation chain. One key component of yard management is yard flow, which involves the movement and handling of yard containers and trailers within the yard.

Efficient yard flow requires proper planning and processing, as well as real-time visibility of yard activities. Yard optimization software, equipped with GPS tracking and yard automation capabilities, can expedite yard handling and improve just-in-time efficiency.

Yard flow encompasses various aspects of yard management, including yard inbound and outbound operations. It involves the coordination of yard trucks, yard resources, and yard loads, ensuring smooth and safe movement throughout the yard.

Effective yard flow also requires dock control and safety measures to prevent accidents and ensure proper handling of pallets. Yard tracking and yard dispatching systems can enhance yard productivity by enabling real-time monitoring and routing optimization.

In conclusion, yard flow is a critical component of yard management that focuses on the efficient movement and handling of containers, trailers, and loads within the yard. By implementing the necessary software, automation, and safety measures, organizations can optimize their yard operations and maximize efficiency in the transportation chain.

In order to maximize efficiency and productivity in the yard, it is essential to implement effective yard management strategies. One key aspect of this is optimizing equipment utilization. By using a yard tracking system, automation, and software, yard operations can be streamlined and optimized.

Efficiency in the yard starts with organizing the yard flow. By understanding the yard capacity, yard equipment can be utilized to its maximum potential. Yard optimization involves monitoring yard metrics and implementing inventory control. With a well-planned yard flow, freight yards can ensure compliance and easily communicate with other departments.

Implementing a yard automation system can greatly improve yard productivity. This can include dock control and monitoring inventory movements in real time. By using yard software systems, yardfuls of goods can be efficiently dispatched and transported to the appropriate warehouses.

Optimizing equipment utilization also involves streamlining yard procedures. By strategically planning the movement and handling of pallets and other supplies, time and resources can be saved. Yard jockeys and yarders play a crucial role in the efficient utilization of equipment in the yard.

In conclusion, optimizing equipment utilization in the yard is key to maximizing efficiency and productivity. By implementing yard automation, utilizing yard software systems, and organizing the yard flow, yards can improve their operations and achieve higher levels of efficiency. This leads to better inventory control, faster receiving and dispatching, and ultimately, improved supply chain management.

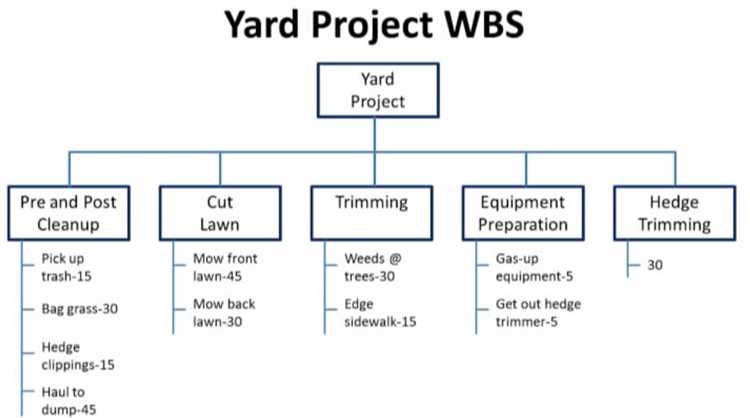

Efficient yard management and yard flow strategies are essential for maximizing productivity and efficiency in the supply chain. An effective yard layout design plays a crucial role in optimizing yard performance and utilizing yard resources effectively. By strategically planning the layout of the yard, including storage areas, receiving and shunting areas, and material handling zones, companies can minimize yard traffic and streamline the flow of goods in and out of the yard.

Implementing advanced yard technology, such as a yard tracking system and GPS, can further enhance yard logistics and improve yard productivity. These technologies enable real-time tracking of containers and yard handling equipment, allowing for better planning and scheduling of yard activities. Additionally, integrating yard software systems can automate yard operations, improving yard control and organizing the flow of containers and goods throughout the distribution process.

In addition to layout design and technology, effective dock management and yard handling equipment maintenance and inspection are also vital for optimizing yard flow and maximizing efficiency. A well-organized dock control system ensures smooth transitions between trucks and the yard, minimizing delays and bottlenecks. Regular maintenance and inspection of yard handling equipment help prevent breakdowns and ensure efficient material handling.

Overall, by implementing effective yard layout design, utilizing advanced technology, and maintaining proper dock control and yard handling equipment, companies can achieve a well-organized yard flow that maximizes productivity and efficiency in the supply chain.

The key to maximizing efficiency in yard management and yard flow strategies is the effective utilization of technology. Implementing a yard tracking system allows for yard handling processes to be monitored and managed in real time. This software integrates with other systems such as maintenance, dispatching, and planning to provide a comprehensive view of yard operations. By tracking yard container movements, loading and unloading activities can be expedited, optimizing the flow of goods through the yard.

Yard optimization is also enhanced through the use of technology. Yard staging can be planned and organized based on real-time data and yard performance metrics. Throughput can be maximized by strategically positioning trailers and equipment. A yard control system monitors and manages yard compliance, ensuring that safety procedures and regulations are followed. Additionally, a yard security system can be implemented to protect valuable assets and prevent theft.

The utilization of GPS technology allows for accurate tracking and inspection of yard operations. Yard trucks equipped with GPS can efficiently navigate the yard, minimizing delays and optimizing route planning. Equipment inspections can be conducted in a timely manner, preventing breakdowns and reducing downtime. By utilizing technology, the entire yard flow process can be streamlined, resulting in increased efficiency and cost savings.

In today’s just-in-time supply chain, utilizing technology for yard management is crucial. By implementing a yard tracking system and utilizing GPS technology, yard performance can be improved, leading to shorter lead times and higher customer satisfaction. Efficient yard management is a yardstick for measuring the overall efficiency of a supply chain, and investing in technology is a key component of achieving optimal yard flow and maximizing efficiency.

Effective yard management and yard flow strategies are crucial for maximizing efficiency in warehouse operations. Yard capacity planning plays a vital role in optimizing yard performance and overall supply chain management. By implementing effective yard flow strategies, communication between different departments such as dock management, logistics, and inventory control can be improved, leading to better coordination and streamlined operations.

Yard traffic and handling are critical factors that need to be managed efficiently to ensure smooth supply chain operations. By implementing yard software systems and utilizing GPS and tracking technologies, it becomes easier to monitor yard container movements, loading and unloading processes, and optimize yard routing. Yard technology also enables real-time visibility of yard load and provides data for analysis to identify bottlenecks and implement necessary improvements.

Another important aspect to consider in yard capacity planning is yard layout. Designing an efficient yard layout helps in maximizing yard space utilization and enhancing throughput. Automation and the use of yard handling equipment further contribute to improving yard flow and minimizing handling time. By synchronizing yard handling with order management, warehouse operations can be streamlined, leading to faster processing and reduced time for both inbound and outbound tasks.

Yard metrics and yardage can serve as a yardstick to assess the efficiency of yard management and facilitate continuous improvement. By analyzing yard performance data and using yard software systems, it becomes possible to identify areas for optimization and implement proactive measures. Additionally, yard safety should also be a priority in yard capacity planning, ensuring the implementation of safety protocols and guidelines to prevent accidents and protect personnel and assets.

In conclusion, implementing yard capacity planning and effective yard flow strategies is essential for maximizing efficiency in warehouse operations. By utilizing yard software systems, incorporating automation and yard handling equipment, optimizing yard layout, and focusing on communication and coordination, businesses can enhance yard performance, reduce bottlenecks, and improve overall supply chain management.

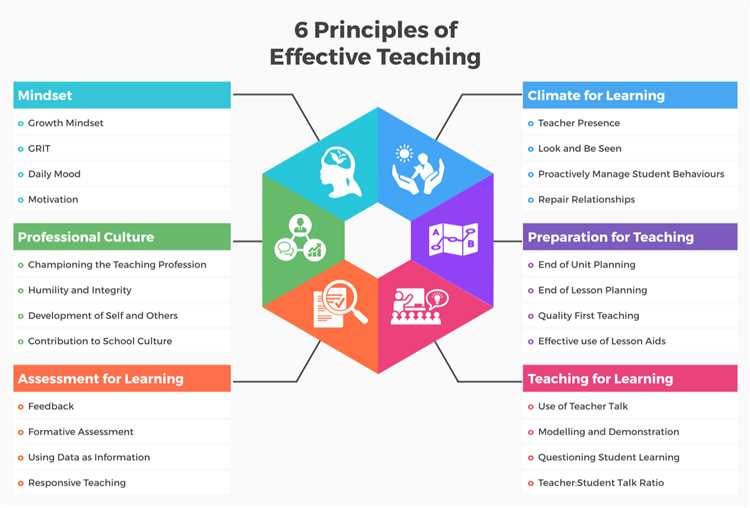

In the fast-paced world of transportation and logistics, effective communication and coordination are crucial for maximizing efficiency and optimizing yard flow. By establishing clear lines of communication between different departments and facilities, companies can ensure that transportation and logistics operations run smoothly. This includes coordinating activities such as shunting, yard organization, and yard inspection.

Utilizing advanced yard management software and yard tracking systems, companies can gain greater visibility and control over yard performance. These tools help in monitoring yard productivity, inventory control, and equipment availability. By automating yard processes, companies can expedite the picking, unloading, loading, and storage of yard containers and pallets. This not only improves efficiency but also enhances security and reduces the risk of errors.

With efficient yard flow strategies in place, companies can better manage the supply chain and expedite the movement of goods. By optimizing yard logistics and coordinating with transportation and distribution operations, companies can reduce bottlenecks and delays. This leads to faster turnaround times, improved customer satisfaction, and increased profits.

To further enhance yard flow and efficiency, companies should regularly inspect and maintain their yard equipment. This helps in identifying any issues and ensuring that the equipment is in good working condition. By keeping a close eye on yard inventory and making necessary adjustments, companies can prevent overstocking or shortages and ensure that the right amount of supplies is available at all times.

In conclusion, effective yard management and coordination with transportation and logistics are essential for maximizing efficiency and optimizing yard flow. By utilizing advanced software and tracking systems, companies can gain greater visibility and control over yard operations. By implementing efficient yard flow strategies, companies can expedite the movement of goods, improve customer satisfaction, and increase profits.

Safety is of utmost importance in yard operations to ensure the well-being of workers and the protection of yard assets. The yardmaster plays a crucial role in overseeing yard operations and monitoring the flow of inventory in and out of the yard. By implementing efficient yard handling procedures and yard tracking systems, safety risks can be minimized.

Effective yard design and layout are essential for optimizing yard flow and maximizing efficiency. A well-organized yard with clear yardarm markings and designated areas for inbound and outbound yard traffic helps streamline dispatching and reduces the risk of accidents. Utilizing yard equipment, such as yard trucks, that are properly maintained and equipped with safety features, further enhances the safety of yard operations.

Having real-time visibility into yard performance and yard utilization through a yard tracking system allows for better planning and decision-making. By monitoring yard activities and tracking the movement of yard assets, managers can identify bottlenecks and inefficiencies in the yard flow, leading to improved productivity and yard performance.

Communication and coordination among all stakeholders involved in yard operations, including drivers, dispatchers, and warehouse personnel, are crucial for ensuring safety. Regular communication channels should be established, and protocols for reporting and addressing safety concerns should be implemented. Safety training and awareness programs should also be conducted to educate employees on safe yard handling practices and emergency procedures.

To promote safety and efficiency in yard operations, it is important to regularly review and update yard procedures and incorporate feedback from employees. Evaluating the effectiveness of yard systems and making necessary modifications to optimize safety and productivity is an ongoing process. By prioritizing safety in yard operations and implementing effective yard flow strategies, organizations can create a safe and productive working environment.

Efficiency in yard management is crucial for optimizing material handling and ensuring smooth operations. One key aspect of achieving efficiency is through effective yard flow strategies. Yard flow refers to the movement of various items and equipment within the yard, including containers, pallets, tow tractors, forklifts, and other yard handling equipment.

To enhance yard flow, yard design and organization play a significant role. An optimized rail yard layout allows for efficient processing, unloading, staging, and dispatching of containers and other materials. Proper yard inventory and monitoring systems enable real-time visibility of yard resources, ensuring effective yard utilization.

Maintaining yard security is also essential for uninterrupted operations. Implementing yard procedures and maintaining appropriate security measures ensures the safety of yardful content, equipment, and personnel. With effective storage and automation, yardmasters can efficiently allocate yard space and coordinate transportation activities.

To improve yard flow and overall efficiency, continuous monitoring and evaluation of yard operations are necessary. Regular maintenance of yard handling equipment and implementing technological advancements, such as yard management systems (TMS), contribute to optimizing yard flow and reducing operational downtime.

Distribution companies have implemented various yard management strategies to maximize efficiency and improve overall yard flow. One successful strategy is the use of GPS technology and yard tracking systems to monitor and manage yard operations. These systems provide real-time information on the location and status of yard resources, allowing for better coordination and planning.

Another case study focused on yard inspection and safety procedures. By implementing regular yard inspections and enforcing strict safety protocols, the company was able to reduce accidents and improve yard safety. This not only protected employees and equipment but also improved overall yard performance.

Yard organization and handling equipment optimization were also key strategies in optimizing yard flow. By implementing efficient yard organization methods and utilizing the right yard handling equipment, companies were able to improve throughput and reduce delays in yard operations. This resulted in faster order management and improved on-time delivery.

One case study focused on optimizing yard inbound and outbound processes. By streamlining yard procedures and implementing efficient dock management systems, companies were able to reduce waiting times for trucks and improve yard capacity. This resulted in faster unloading and loading of freight, increasing overall yard productivity and throughput.

In terms of security and protection, companies implemented yard security systems and employed trained yardmen or yardmasters to ensure the safety and integrity of the yard warehouse. These measures not only protected assets but also helped in preventing loss or theft of goods and materials.

Furthermore, the implementation of yard technology such as forklift automation and just-in-time transportation systems significantly improved yard flow and productivity. This allowed for smoother and more efficient movement of goods, reducing bottlenecks and improving overall yard performance. Additionally, companies optimized their yard chain processes by aligning yard activities with warehouse and logistics operations, resulting in better synchronization and coordination.

In conclusion, successful companies have implemented a combination of strategies such as optimizing yard organization, implementing efficient yard procedures, utilizing yard technology, and focusing on yard safety and security. These case studies demonstrate the importance of effective yard management strategies in maximizing efficiency and improving overall yard flow in distribution operations.

Yard management refers to the process of organizing and tracking the movement of trailers, trucks, and other assets within a yard or distribution center. This includes activities such as checking in and out trucks, assigning dock doors, and optimizing the flow of trailers and containers.

Effective yard management is essential for maximizing operational efficiency in a warehouse or distribution center. It helps to reduce congestion, streamline processes, minimize delays, and improve overall productivity. Additionally, it enables real-time visibility and better inventory control.

Some successful yard management strategies include implementing a yard management system (YMS) to automate and streamline processes, utilizing real-time location tracking technologies such as RFID or GPS, adopting standardized yard management procedures, and optimizing yard layout and signage for better trailer movement.

Sure! One example is a large retail distribution center that implemented a YMS and utilized real-time location tracking technologies. This allowed them to optimize yard operations, reduce wait times, and increase the number of trucks being loaded and unloaded each day. As a result, they were able to improve their shipping and receiving efficiency by 20% and reduce labor costs by 15%.

Implementing successful yard management strategies can have several benefits, including improved operational efficiency, reduced costs, increased productivity, better customer service, enhanced inventory accuracy, reduced congestion, and improved safety and security in the yard. It also provides real-time visibility and data for better decision-making.