Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

When it comes to incorporating a systematic approach for yard management, inventory optimization plays a crucial role in ensuring maximum efficiency and productivity. By implementing a well-defined procedure, facility owners can enhance their organization framework and streamline their inventory tracking, storage management, and assortment management.

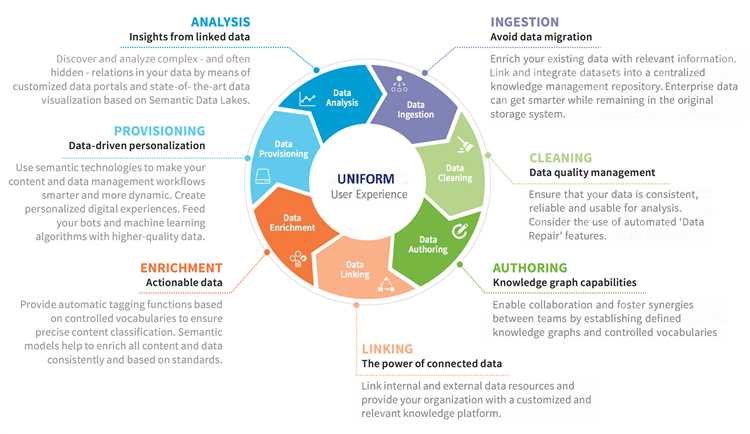

To start consolidating and categorizing your yard, it’s essential to have a comprehensive list of all the items or assets you have in stock. By creating a structured inventory control system, you can easily manage and track the flow of goods within your facility. This approach helps in handling and assimilating incoming and outgoing stock, while also providing better visibility for distribution control and safety.

Logistics optimization is a crucial aspect when it comes to handling and managing your yard efficiently. By implementing logistics automation systems and the latest technology in delivery tracking, warehousing processes can be streamlined. This includes gathering and inclusion of stock, as well as optimizing the receiving process and dispatch to ensure consistency control and efficient inventory control.

Efficient assortment management and proper resource allocation system are essential for a well-organized yard. An effective transportation system, coupled with logistics automation, can help improve the overall efficiency and productivity. By implementing a robust inventory control system and utilizing the right array of tools and technologies, facility owners can ensure maximum efficiency and effectiveness in their yard operations.

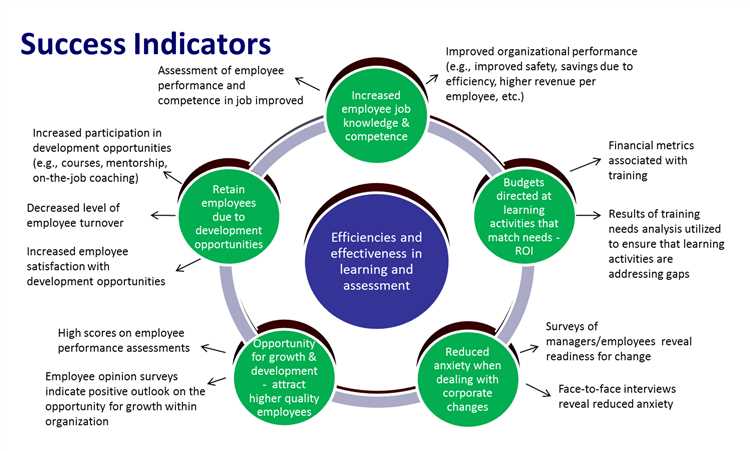

When it comes to maximizing the efficiency of your yard, proper assessment and categorization are essential steps. Supply chain planning, logistics optimization, and inventory system optimization are just a few tactics that can be utilized.

Firstly, it is crucial to conduct a comprehensive assessment of your yard to determine its current state and potential areas for improvement. This assessment involves scrutinizing various aspects such as yard safety management, handling optimization, and yard control. By identifying any weaknesses or inefficiencies, you can begin to formulate a plan to address them.

Once the assessment is complete, the next step is yard categorization. This involves the classification and amalgamation of different yard components, including stock, pallet management, load management, and assortment management. By categorizing the yard’s resources and assets, you can optimize their usage, reduce clutter, and facilitate easier tracking and coordination.

One key aspect of yard categorization is the implementation of a robust inventory system optimization. With an efficient inventory system in place, you can accurately monitor stock levels, track movement, and ensure timely replenishment. Proper inventory controlling is crucial for smooth operations and minimizing delays in order fulfillment.

In addition to inventory management, the organization framework of the yard should be optimized. This includes routing, sequencing, and formation of the yard. By strategically arranging the yard layout and implementing effective organization practices, you can streamline the flow of goods, improve coordination, and minimize congestion.

Furthermore, the implementation of a reliable dispatch system and fleet management is essential. These systems enable efficient distribution control and ensure timely delivery of goods. By optimizing the dispatch system and fleet, you can minimize delays, improve customer satisfaction, and reduce transportation costs.

Overall, assessing your yard and categorizing its various components is a vital step towards maximizing efficiency. By implementing supply chain planning, logistics optimization, and inventory system optimization, you can enhance yard control, streamline operations, and improve overall productivity in your yard.

In the context of efficient yard management, understanding the layout and categorizing your yard can significantly streamline the logistical processes and enhance operational efficiency. This approach involves implementing pallet management strategies, logistics tracking, and inventory control methods.

Yard categorizing begins with assorting and categorizing different items or goods based on their attributes and characteristics. This process allows for effective allocation and storage management, as well as the formation of a system to facilitate the logistics process efficiently.

By categorizing products, it becomes easier to manage and control the storage system, ensuring that items are organized and stored in a logical order. This organization can be further enhanced by implementing a sequencing order strategy, which optimizes the shipping process by arranging items in a specific sequence according to their delivery requirements.

Another option for categorizing the yard is by grouping similar products or items together, allowing for easier access and retrieval during order fulfillment or delivery. This technique can be especially useful in the warehousing process, where goods need to be easily located and assembled for shipping.

Yard categorizing also facilitates the unload process, as products can be sorted and merged according to their specific categories, reducing the time required for unloading and increasing overall efficiency. Additionally, integrating logistics automation can further enhance the categorizing process, as it enables operations to be carried out more systematically and reduces the margin for errors.

Overall, categorizing your yard and implementing efficient yard management strategies can significantly enhance the logistical operations and optimize the delivery and load processes. By rationalizing and streamlining the logistics process, organizations can improve their operational efficiency, reduce costs, and ensure timely and accurate deliveries.

Before embarking on the process of consolidating and categorizing your yard for maximum efficiency, it is crucial to evaluate the functionality of the current elements in your yard. This evaluation involves assessing the assimilation and consistency of your yard’s processes, logistics distribution, and inventory tracking systems.

One important aspect to consider is the distribution control and tracking protocol in place. This ensures that the packing, sequencing, and placement of items in your yard are optimized for efficient logistics planning. It also allows for inventory optimization and tracking, ensuring that the right items are available when needed.

Structuring your yard in a logical and organized manner is another key factor in maximizing efficiency. By implementing an assortment management system, you can categorize items based on their characteristics and needs. This allows for better logistics tracking and ensures that items are easily accessible when required.

Categorizing your yard involves dividing it into different sections based on specific criteria. This tactic allows for better organization and systematization of the inventory, enabling faster and more accurate inventory tracking. For example, you can create divisions for different types of products, such as equipment, tools, or materials.

Once your yard is categorized, it is essential to plan the placement and sequencing of items strategically. This ensures that items are located in the most convenient and efficient positions for easy access. By implementing a yard control system, you can consistently monitor and adjust the placement and sequencing of items as needed to optimize operations.

In summary, evaluating the functionality of current elements, such as logistics distribution, packing, tracking, and inventory tracking systems, is crucial before undertaking the process of consolidating and categorizing your yard. By structuring and categorizing your yard based on specific criteria, and implementing a system for consistent inventory tracking and control, you can maximize efficiency and improve your overall yard management.

In order to maximize efficiency in yard management, it is important to identify areas for improvement. This can be done through a thorough analysis of the current yard operations and the implementation of yard logistics solutions. One area that often needs improvement is transportation. By streamlining transportation processes, such as pallet and bulk handling, and synchronization with operational planning, companies can greatly improve their yard efficiency.

An important step in maximizing yard efficiency is the categorizing and structuring of the yard. This involves the rationalization and grouping process of inventory, handling, and receiving. By categorizing the yard based on specific criteria, such as product type or order fulfillment, companies can easily locate and access their inventory. This also allows for better inventory management and stockpile management, reducing the risk of overstocking or stockouts.

One way to categorize the yard is through the use of automation. By implementing automated solutions, companies can streamline the categorizing and unload process, reducing the time and effort required for manual categorization. This also improves safety in the yard, as automated systems can handle heavy loads and reduce the risk of accidents.

Another important aspect of yard categorizing is the assimilation of facilities and infrastructure. By merging and consolidating different yards into one central location, companies can optimize their inventory and improve supply chain planning. This allows for better facility management and inventory optimization processes.

In conclusion, by identifying areas for improvement and implementing yard categorizing solutions, companies can greatly improve their yard efficiency and maximize their operational planning. By streamlining transportation, implementing automation, and categorizing the yard, companies can achieve better inventory management, improve safety, and enhance their overall yard logistics.

Efficient yard management involves implementing zones and categorizing the yard to optimize dispatch, inventory tracking, and allocation. By strategically setting up different areas within the yard, companies can improve their logistics, supply chain optimization, and handling processes.

To achieve maximum efficiency, yard categorizing should align with the company’s supply chain optimization goals. By implementing zones and utilizing proper infrastructure, companies can effectively manage their yard and enhance their overall operational performance.

As part of the yard categorizing process, it is essential to designate a specific area for relaxation and rest. This relaxation zone allows workers to recharge and rejuvenate, increasing their productivity and overall well-being. By having a dedicated space for relaxation, it becomes easier to allocate resources effectively and adhere to a streamlined process. This protocol not only benefits the workers but also contributes to the efficiency of the yard control and shipping process.

Effective yard categorizing entails careful planning and grouping of different items based on their specific attributes and requirements. An inventory tracking system plays a crucial role in this process, allowing for efficient pallet and load management. It enables logistics management to set a combination of infrastructure, dispatch, and automation to improve the overall procedure and framework of resource allocation. Additionally, a group management system enhances the inclusion of various elements and optimizes the distribution management for better categorizing and systematization of the yard.

Another technique in yard categorizing is the configuration and staging of items, which helps in the efficient organization and transportation system. A well-planned strategy for supply chain optimization and supply chain management is essential to ensure smooth operations and inventory control. By implementing these various techniques and systems, the yard can be effectively categorized and optimized for maximum efficiency.

Creativity and thoughtful planning are essential when designing a play area for children. By incorporating various elements, such as slides, swings, and climbing structures, a rich and engaging play environment can be created for kids to explore and enjoy. The design should prioritize safety, with sturdy infrastructure and soft, impact-absorbing surfaces.

Additionally, it is crucial to consider categorizing the play area based on different age groups and abilities. This categorization ensures that children of all ages and skill levels can engage in appropriate activities. Including areas for imaginative play, sensory exploration, and physical challenges will provide a holistic and inclusive play experience for all children.

In order to optimize yard management and improve logistics planning, categorizing the yard into different areas can be highly beneficial. By allocating specific spaces for various functions, such as receiving, distribution, and storage, the overall flow and organization of the yard can be enhanced.

Clustering similar items or equipment together within the yard helps facilitate easier inventory management and load handling. This categorization allows for standardized processes and protocols, ensuring efficient routing and delivery of containers or bundles. By implementing a robust inventory system and utilizing appropriate logistics frameworks, such as yard logistics and supply chain management, yard centers can effectively streamline their operations and improve overall productivity.

Effective categorizing and organization within the yard also helps with load management and distribution control. By standardizing the formation and bundling of goods, the handling and delivery process becomes more efficient, saving time and reducing errors. Dividing the yard based on the specific needs and requirements of different products or materials further optimizes load handling and ensures smooth logistics operations.

When it comes to establishing a gardening space, organization is key to maximizing efficiency. By categorizing your yard and implementing a strategic order fulfillment process, you can streamline the delivery and storage management of your gardening materials, ensuring that everything is easily accessible and in the right place.

One effective strategy is to standardize your yard by grouping similar items together. This could involve creating designated areas for tools, plant pots, and gardening equipment. By keeping inventory organized and using a sequencing technique, you can ensure easy access and quick retrieval of items when needed.

Storage management also plays a crucial role in establishing an efficient gardening space. Using containers or bundling items together can help keep your yard tidy and prevent clutter. Implementing an inventory tracking system can further enhance this process, allowing you to easily locate and monitor your stockpile of gardening materials. This can be complemented by a dispatch system, which ensures that items are distributed in a timely manner.

In order to optimize routing and handling processes in your gardening space, yard categorizing is essential. By ranking items based on their frequency of use, you can prioritize their placement and ensure that frequently accessed materials are easily reachable. This can be done by clustering related items together, creating a harmonious distribution center within your yard.

Yard safety management should also be a consideration when categorizing your yard. Allocating space for safety equipment and implementing safety protocols can help prevent accidents and injuries. This can be integrated into your overall yard categorizing system to ensure that safety measures are always in place.

Finally, utilizing a combination of techniques such as routing optimization and inventory control can help achieve operational efficiencies in your gardening space. These techniques allow for the most efficient use of space and resources, ensuring that your gardening materials are readily available and easily accessible.

In order to optimize the operational efficiency of your yard, it is important to establish a well-organized storage and utility area. This involves setting up a logical configuration and partitioning of your yard space. By implementing efficient yard management strategies and logistics network integration, you can consolidate and categorize your yard for maximum efficiency.

Yard categorizing involves the grouping and categorization of items within your yard based on their specific needs and requirements. This can include categorizing items based on their size, weight, fragility, or other relevant characteristics. By categorizing your yard, you can better manage and optimize the handling and distribution of items, ensuring that they are located in the most appropriate areas for easy access and efficient utilization.

Implementing proper yard logistics and supply chain planning is crucial for the successful categorization and consolidation of your yard. By effectively managing your yard, you can enhance your warehouse operations, inventory tracking, and distribution control. This synchronization and integration of yard management with other aspects of your supply chain can lead to improved efficiency and overall performance.

Additionally, yard safety management should be a priority when consolidating and categorizing your yard. Proper handling optimization and inventory optimization techniques should be implemented to ensure the safe and efficient movement and storage of items. This includes optimizing the receiving and unload process, as well as implementing stockpile management strategies to prevent congestion and maximize space utilization.

A well-managed yard can greatly benefit from incorporating a designated social gathering spot. This area can serve as a place for employees and customers to interact and build relationships, fostering a sense of camaraderie and teamwork. By intentionally creating a space where people can gather and collaborate, yard management can improve communication and enhance overall efficiency.

Another important aspect of efficient yard management is categorizing and organizing different areas of the yard. This involves inventory controlling, streamlining, and synchronizing the allocation of various resources and assets. By implementing a robust protocol for systematizing the yard, logistics tracking and assortment management becomes more effective.

In terms of yard safety, consistency is crucial. By strategically arranging and grouping items in the yard, potential hazards can be minimized and safety procedures can be easily followed. This helps to create a safer and more secure environment for employees and visitors.

Furthermore, efficient storage management plays a key role in optimizing the shipping process within the yard logistics network. By implementing routing optimization and utilizing innovative automation technologies, the fleet can maximize its strategy for sortation, assimilation, and bulk packing. This ensures that items are properly stored and ready for shipping at any given time, improving overall logistics management.

To achieve consensus and maintain a well-functioning yard, it is important to incorporate an effective approach to unload and storage. This includes developing a structured system for packing and arranging items, as well as implementing efficient storage techniques. By streamlining these processes, the yard can improve its overall efficiency and minimize delays in the shipping process.

In summary, incorporating a social gathering spot and categorizing the yard are crucial components of efficient yard management. These practices help to foster collaboration, improve communication, and enhance overall productivity. By implementing a comprehensive strategy for logistics management, the yard can create a streamlined and well-structured environment that benefits both employees and customers.

In order to maximize efficiency in your yard, it is essential to implement a comprehensive yard categorizing and arrangement system. This system will enable you to streamline your warehousing process and enhance operational efficiencies throughout your yard.

One key aspect of this system is logistics automation. By utilizing automation technology, such as fleet management software, you can optimize the routing and handling process of your inventory. This automation allows for the efficient grouping and structuring of items, improving both storage control and transportation logistics.

The grouping process is another important tactic in yard categorizing. It involves the careful arrangement and aggregation of similar items, creating an organized layout for easy access and stockpile management. This grouping ensures that items are aligned for quick ordering and reduces the time spent searching for specific items.

An effective inventory system is also crucial for maximizing efficiency. By implementing a comprehensive inventory plan, you can keep track of stock levels, monitor utilization rates, and identify slow-moving items. This approach allows for better logistics planning and improves overall operational efficiency.

Yard safety management is another key consideration in yard categorizing. By implementing proper storage and handling protocols, you can ensure the safety of your workers and prevent accidents. Additionally, by implementing safety measures such as bulk storage facilities and proper alignment of items, you can optimize space utilization and minimize inventory damage.

Overall, through a comprehensive yard categorizing and arrangement system, which includes automation, grouping, and safety management, you can achieve maximum efficiency in your yard. This will result in improved operational efficiencies, streamlined logistics, and ultimately a more successful and profitable business.

When it comes to maximizing efficiency in your yard, organizing tools and equipment is essential. By setting up a clear and concise arrangement system, you can streamline the process of locating and retrieving the items you need.

A consensus should be reached on the best method of categorizing and grouping tools and equipment in order to ensure easy access and quick retrieval. This could involve incorporating a series of shelves or racks to store smaller items, or setting up designated areas for larger equipment.

An inventory system should be put in place to keep track of all tools and equipment, including their quantity and condition. This can be done through the use of a warehouse management software or a manual inventory tracking system.

When new tools or equipment are delivered to the yard, they should be immediately unloaded and added to the inventory. This ensures that all items are accounted for and ready for use.

Yard categorizing is another important aspect of maximizing efficiency. By categorizing the yard into different sections based on usage or type of equipment, you can easily locate and retrieve items when needed.

A resource allocation system can be implemented to ensure that each section of the yard is utilized effectively. This could involve assigning specific areas for certain equipment or grouping similar items together for easy access.

Fleet management plays a crucial role in yard categorizing. By efficiently managing the movement and storage of equipment, you can minimize downtime and maximize productivity.

The inclusion of automation in the yard categorizing process can further streamline operations. Automating tasks such as equipment dispatch and fleet management can greatly improve efficiency.

In conclusion, organizing tools and equipment, as well as categorizing the yard, is vital for maximum efficiency. By implementing a consolidated operation that includes a clear arrangement system, inventory tracking, and efficient resource allocation, you can streamline processes and improve overall efficiency in your yard.

Some essential tools for organizing include storage bins, shelves, labels, and drawer dividers.

Storage bins provide a designated space for items, making it easier to group and organize them. They also help to create a clutter-free environment.

Shelves provide additional vertical storage space, allowing you to keep items off the floor and organized in an easily accessible way.

Labels help to identify the contents of storage bins, drawers, and shelves, making it easier to find and retrieve specific items when needed.

Drawer dividers create separate compartments within a drawer, allowing you to keep different items organized and preventing them from getting mixed up.

Yes, there are various digital tools and apps available that can help with organizing. These include virtual to-do lists, calendar apps, and task management tools for keeping track of deadlines and organizing digital files.