Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

A Container Depot Management System (CDMS) is a powerful tool that can greatly enhance the efficiency and organization of container yards. By providing real-time tracking and monitoring, CDMS enables logistics companies to streamline their operations, improve productivity, and reduce costs.

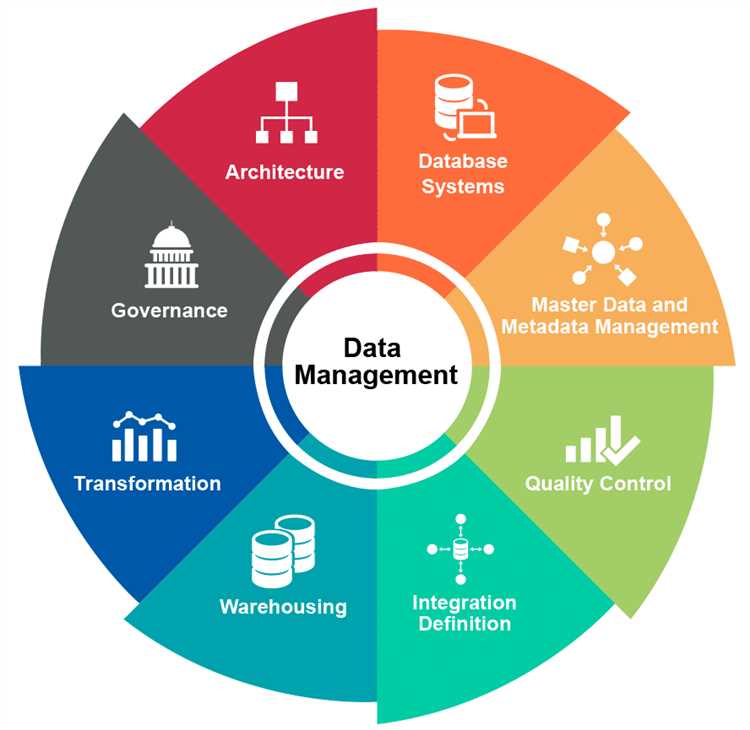

One of the key features of CDMS is its integration with other systems such as Warehouse Management Systems (WMS) and Transportation Management Systems (TMS). This integration ensures seamless communication and coordination between different processes, such as inventory control, routing, dispatching, and driver allocation.

With a CDMS, container yards can automate many manual tasks and processes, such as gate operations, container moves, and equipment management. This automation not only saves time and reduces human error, but also improves the overall performance and security of the yard.

Another benefit of CDMS is the ability to track and monitor container availability and allocation in real-time. This allows logistics companies to optimize their container storage and loading processes, ensuring that the right containers are available at the right time for shipping.

CDMS also provides comprehensive analysis and reporting capabilities, allowing logistics companies to gain valuable insights into their operations and make data-driven decisions. This includes analyzing container movements, detention times, repair needs, and trailer utilization, among other key metrics.

In summary, a Container Depot Management System is a crucial asset for logistics companies, bringing together various systems, automating processes, improving efficiency, and enhancing overall organization. By implementing a CDMS, companies can optimize their resources, streamline their operations, and ultimately improve their profitability and customer satisfaction.

A Container Depot Management System is a comprehensive software solution designed to streamline and optimize the execution of container depot operations. It provides a range of functionalities including container inspection, order tracking, arrival and departure notifications, fleet management, workflow optimization, and asset management.

The system enables efficient handling of containers throughout their lifecycle, from arrival at the depot to their final destination. It ensures compliance with safety regulations and maximizes capacity utilization by providing real-time visibility into container availability and allocating resources accordingly.

With advanced analytics capabilities, the system enables data-driven decision-making by providing insights into key performance indicators, such as container turnaround time, detention charges, and driver performance. This allows for proactive planning and optimization of transportation and yard management processes.

The Container Depot Management System seamlessly integrates with other supply chain management systems, such as warehouse management systems (WMS) and shipping port systems, enabling end-to-end visibility and control over container movements. It facilitates efficient handling of various container types, including full containers, less-than-container loads (LCL), and empty containers.

Key features of a Container Depot Management System include customer reservation and service management, equipment maintenance and dispatch control, unloading and loading operations, and rail and trucking schedule coordination. The system provides real-time updates on container status and location, ensuring accurate tracking and efficient utilization of resources.

Overall, a Container Depot Management System plays a crucial role in improving efficiency and organization in container depot operations. By automating manual processes, optimizing workflows, and providing real-time visibility, it streamlines the management of containers and enhances the performance of supply chain operations.

A container depot management system offers various benefits to container yards, ports, and logistics companies. By implementing this system, businesses can enhance their supply chain visibility and improve overall efficiency.

Implementing a container depot management system can greatly enhance the efficiency and control of inventory tracking. By utilizing yard management software, seamless monitoring and control of container moves can be achieved within the container yard. This allows for real-time tracking of containerized cargo from arrival to departure, ensuring compliance with safety regulations and optimizing overall performance.

The use of mobile applications in the container depot management system enables convenient and efficient order tracking and driver management. With a truck appointment system and telematics, the scheduling and execution of container moves can be streamlined, reducing transit time and cost.

Furthermore, the container depot management system offers enhanced inventory control by providing comprehensive reporting and analytics. This allows for better tracking of assets, such as LCL and reefer containers, and improved workflow management.

In conclusion, by implementing a container depot management system, businesses can greatly enhance their inventory tracking and control capabilities. The use of software, mobile applications, and advanced tracking technologies enables better management and optimization of container moves, leading to improved efficiency, reduced costs, and enhanced overall performance.

Implementing a container depot management system (CDMS) can greatly improve efficiency and organization in streamlining operations for container yards. By integrating supply chain control and reservation systems, drivers can easily check container availability and make reservations for pick-up or delivery, reducing wait times and improving overall satisfaction.

Automated processes within the CDMS also help optimize capacity management. The system can monitor container storage and order tracking, alerting logistics managers to available containers and allowing for quicker allocation. This eliminates unnecessary costs associated with over-packing or under-utilizing container capacity.

The use of automated gate activities in the CDMS further improves efficiency by reducing manual labor. Gates can be equipped with technology that allows for quick and accurate container identification and documentation, expediting the truck entry and exit process. This automation also minimizes errors and enhances communication between shipping lines, drivers, and container yards.

A cloud-based CDMS offers several advantages for streamlining operations. It allows for real-time monitoring of container availability, detention, and storage, providing accurate information to logistics managers and helping prevent delays or bottlenecks. Additionally, the system enables remote access, facilitating collaboration and communication among different stakeholders in the logistics management process.

Mobile applications integrated into the CDMS enhance dispatch and fleet management. Drivers can receive real-time updates on containerization and packing instructions, ensuring smooth operations and reducing the risk of damages during transit. The automation of processes and data collection in the CDMS also reduces paperwork and manual data entry, saving time and minimizing errors.

In conclusion, implementing an automated and cloud-based CDMS offers significant advantages in improving efficiency and organization within container yards. Through automated processes, such as reservation systems, gate activities, and order tracking, operations can be streamlined, leading to cost savings, better communication, and enhanced logistics management. By adopting the use of technology in the form of a CDMS, container depots can optimize their operations and deliver better results for their customers.

Implementing a Container Depot Management System (CDMS) can help reduce labor costs and increase productivity in a container depot. The use of advanced technology such as a Warehouse Management System (WMS) allows for efficient allocation of resources, optimizing processes and reducing the need for manual labor.

With a CDMS, unloading and cargo handling can be automated, reducing the reliance on human workers and decreasing labor costs. Real-time container tracking and integration with the depot’s fleet management system enable efficient routing and allocation, ensuring that containers are easily accessible when needed.

Furthermore, the use of technology in depot management improves productivity by streamlining gate activities. Truck drivers can undergo pre-trip inspections electronically, saving time and reducing delays. The CDMS also provides analysis and analytics for improved decision-making, helping to optimize truck routes and departures.

This technology-driven approach not only improves efficiency but also ensures compliance with safety regulations. The CDMS allows for better reporting and monitoring of processes, enhancing safety and security in the depot. This, in turn, increases customer satisfaction and cargo security.

In summary, integrating a Container Depot Management System into depot operations can significantly reduce labor costs and boost productivity. By automating processes, optimizing routes, and ensuring compliance with safety regulations, depots can operate more efficiently, resulting in cost savings and improved customer satisfaction.

Container Depot Management System (CDMS) offers a web-based platform that allows for optimized space utilization and storage in container depots. By integrating with various technologies such as RFID and telematics, the CDMS provides real-time visibility into the inventory and capacity of the depot, enabling efficient resource allocation and storage planning.

With the CDMS, supply chain visibility is enhanced, allowing shipping lines, trucking companies, and warehouse operators to have better control over their operations. The system streamlines communication and collaboration between different stakeholders, ensuring smooth gate activities, driver routing, and efficient cargo handling.

The integration of the CDMS with EDI and other supply chain systems further improves efficiency by automating processes and eliminating manual errors. This integration enables seamless information exchange between different parties involved in the depot operations, leading to improved resource utilization and reduced costs.

In conclusion, the Container Depot Management System offers a comprehensive solution for optimizing space utilization and storage in container depots. By leveraging advanced technology and facilitating collaboration and communication, the CDMS enables efficient yard operations, cargo handling, and gate activities. With enhanced supply chain visibility and improved resource allocation, the CDMS ensures the smooth execution of depot operations while reducing costs and improving customer satisfaction.

Efficient communication and collaboration are essential in an effective container depot management system. With the implementation of a web-based WMS, shipping companies can streamline their operations and enhance communication between different departments. This enables smooth collaboration between the shipping, repair, and container storage teams, resulting in improved productivity and reduced costs.

Real-time tracking and monitoring capabilities provided by the WMS allow for seamless communication between the terminal and drivers involved in container handling and drayage. This ensures that containers are picked up and delivered on time, improving overall performance and customer satisfaction.

The integration of inventory control and equipment management within the container depot management system enables better collaboration between various teams. The tracking and optimization of inventory levels ensure that the depot can meet the demands of full container loads (FCL) and intermodal shipments, while also managing reefer containers for temperature-sensitive cargo.

Moreover, effective communication and collaboration between the maintenance and repair teams ensure timely execution of equipment maintenance tasks, reducing downtime and increasing safety. The tracking and control of these activities through the container depot management system optimize workflow and improve equipment performance, ultimately saving costs associated with equipment repairs and replacements.

In conclusion, a container depot management system with enhanced communication and collaboration capabilities is crucial for shipping companies. By utilizing a web-based WMS, real-time tracking, and efficient communication between different teams, the depot can achieve better inventory management, seamless workflow execution, and overall cost reduction, leading to improved customer satisfaction and operational efficiency.

To ensure compliance and security in the container depot management system (CDMS), several measures are implemented. The automation of key processes such as arrival, detention, repair, and dispatching of empty containers allows for a more efficient and error-free operation. The system provides real-time analysis and reporting to support supply chain visibility and ensure compliance with industry regulations.

The web-based CDMS platform enhances cargo security by providing a centralized system for managing container moves, storage, and allocation. This system enables seamless planning and optimization of container availability, terminal operations, and driver management. With cloud-based storage, all data is securely stored and easily accessible.

Compliance with industry regulations and standards is essential for maintaining the security of the supply chain. The CDMS includes features that enable compliance with cargo security regulations and standards. It provides tools for monitoring and controlling access to the depot and gate, ensuring that only authorized personnel and vehicles have access to the facility.

The integration of the CDMS with existing systems such as ERP (Enterprise Resource Planning) and FCL (Full Container Load) systems further enhances compliance and security. The CDMS seamlessly integrates with these systems to provide comprehensive supply chain management and visibility, ensuring that all assets and cargo are accounted for and tracked throughout the entire supply chain.

In conclusion, the container depot management system (CDMS) ensures compliance and security by automating key processes, providing real-time analysis and reporting, and integrating with existing systems. This system improves efficiency and organization, enhances cargo security, and ensures compliance with industry regulations and standards. With the CDMS, companies can manage their container depot operations more effectively and maintain a high level of compliance and security in their supply chain.

A container depot management system provides real-time visibility and reporting capabilities for efficient container inventory control and streamlining operations. This ensures that the cost and asset management of containerized cargo are optimized at all times. The system allows for accurate tracking and monitoring of containers from loading to unloading, ensuring compliance with safety regulations and customer satisfaction.

The integration of a container depot management system into logistics operations improves efficiency and organization by providing real-time visibility of container movements and storage. It enables better supply chain control by optimizing routing and yard management, resulting in a reduction in transportation costs and improved overall performance.

The system enables efficient container packing and unpacking, ensuring that containers are loaded and unloaded in a timely manner. It also provides accurate storage and equipment management, allowing for effective utilization of available space and resources. With real-time reporting capabilities, logistics managers can easily track container status, location, and condition, ensuring smooth operations.

The container depot management system also enhances supply chain visibility by providing accurate tracking and monitoring of containers during transport. This improves supply chain control and reduces delays in shipping and drayage, enabling better coordination and communication between different parties involved in the logistics process. Real-time reporting capabilities also allow for effective reefer management, ensuring that temperature-controlled containers are properly monitored and maintained.

With real-time visibility and reporting, the container depot management system enables logistics companies to optimize operational processes, improve efficiency, and ensure compliance with safety regulations. It enhances overall supply chain control and customer satisfaction by streamlining containerized cargo operations and providing accurate tracking and reporting capabilities. The system’s integration into logistics operations brings significant benefits in terms of cost reduction, improved performance, and efficient equipment management.

When it comes to logistics and yard operations, container availability is crucial for efficient loading and unloading of cargo. A container depot management system offers a web-based platform for booking and managing container moves, providing real-time visibility into supply chain processes. This software streamlines inventory management, container tracking, and yard operations, ensuring optimal performance and efficient routing of trailers and drivers.

For growing businesses, scalability and flexibility are essential. A container depot management system allows businesses to easily scale up their operations as their demand increases. With the ability to add more containers, manage a larger fleet, and handle increased cargo volume, businesses can meet the needs of their customers while maintaining high levels of service satisfaction.

The use of a container depot management system also helps businesses comply with safety regulations. By automating processes and providing real-time tracking and monitoring, businesses can ensure that all safety protocols are followed during loading, unloading, and transportation. This not only improves safety but also reduces the risk of accidents and delays, resulting in cost savings and customer satisfaction.

Additionally, the flexibility of a container depot management system extends to mobile applications. Drivers and yard operators can access the system on their mobile devices, allowing for efficient execution of container moves and real-time collaboration with the office. This enables businesses to respond quickly to changes in customer demands, optimize route planning, and minimize demurrage charges.

In conclusion, a container depot management system offers scalability and flexibility for growing businesses in the logistics industry. By providing real-time supply chain visibility, streamlining processes, and ensuring compliance with safety regulations, businesses can improve their efficiency, performance, and customer satisfaction. With the ability to handle increased cargo volume, manage a larger fleet, and optimize container tracking and yard operations, businesses can successfully navigate the challenges of a growing supply chain.

Scalability refers to the ability of a growing business to handle increased workload, expand its operations, and accommodate a larger number of customers or users without experiencing significant issues or performance degradation.

Scalability is important for growing businesses as it allows them to meet the increasing demands of their customers and adapt to changes in the market. It ensures that the business can handle growth without sacrificing performance or customer experience.

Some examples of scalable solutions for growing businesses include cloud computing, virtualization, and automated systems. These technologies allow businesses to easily scale their operations and resources to meet increasing demands.

Flexibility for growing businesses refers to their ability to adapt and respond to changes in the market, customer needs, and business environment. It involves being open to new ideas, being agile, and having the capability to quickly adjust strategies and operations as needed.

Flexibility is important for growing businesses as it allows them to stay competitive in a rapidly changing market. It enables businesses to quickly respond to customer demands, adapt to new technologies, and seize new opportunities as they arise.

Businesses can improve their scalability and flexibility by investing in scalable technologies, such as cloud computing, implementing automated processes, fostering a culture of innovation and agility, and staying up-to-date with market trends and customer needs.