Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

Monitoring the temperature of perishable goods during transportation is crucial for maintaining the quality and safety of goods throughout the supply chain. With the help of telematics and advanced sensor technology, a sustainable and efficient solution can be achieved.

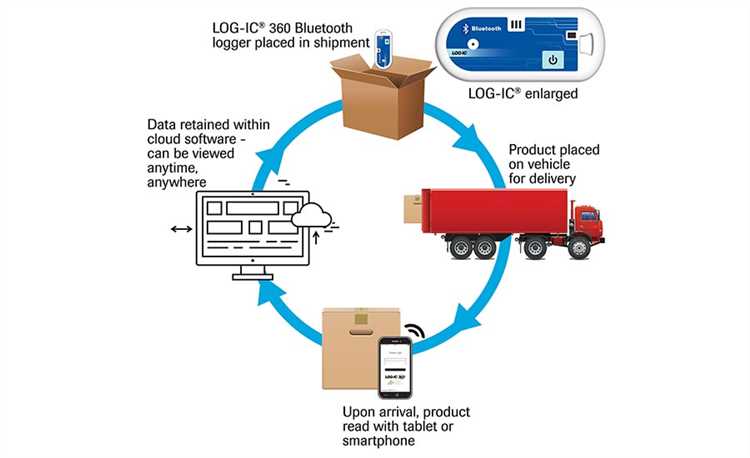

A reefer monitoring system provides real-time and reliable access to accurate data on the temperature and condition of containers, ensuring optimal temperature control. The system utilizes wireless and cloud-based technology for streamlining the management of temperature-controlled shipments.

By using a combination of sensors, the reefer monitoring system tracks and analyzes data to provide proactive alerts and traceability. This data-driven approach enables logistics and supply chain operators to make informed decisions and take necessary actions to ensure the integrity and performance of temperature-controlled equipment.

The reefer monitoring system enhances transparency and visibility by providing accurate data on the environmental conditions inside the container. This enables stakeholders to have a clear understanding of the temperature, humidity, and other critical parameters that affect the quality of goods.

With the implementation of a reefer monitoring system, the cold chain management becomes more efficient and reliable, minimizing the risk of spoiled or damaged goods. By ensuring the optimal temperature control of containers and enhancing the traceability of goods, the system contributes to the overall efficiency and sustainability of the supply chain.

Temperature control is crucial in container shipping as it ensures the integrity and quality of temperature-controlled cargo. The implementation of a temperature-controlled container monitoring system brings several benefits, such as cost savings, stock preservation, and early warning of potential issues.

By using a temperature-controlled container monitoring system, companies can accurately monitor and report temperature performance, resulting in better maintenance and reduced operational costs. The system provides real-time notification of any deviations from the desired temperature range, allowing for prompt action to prevent damage to the cargo.

Integration of the monitoring system with other equipment and systems enhances efficiency and reliability. For example, the system can integrate with pressure and humidity sensors to ensure accurate control of the container environment and reduce the risk of bacteria growth. The system’s intelligent module enables automated data analysis, optimization, and reporting, providing access to transparent and accurate information through a user-friendly dashboard.

With a temperature-controlled container monitoring system, companies can ensure the optimal storage and transportation conditions for temperature-sensitive goods. The advanced automation and optimization capabilities of the system contribute to cost-effectiveness while maintaining the quality of the cargo. The system’s reliable monitoring and control ensure that temperature-sensitive items are delivered intact and in the best possible condition.

The unpredictability of temperature variations can have detrimental effects on goods during transit. Fluctuations in temperature can cause spoilage, reduce product quality, and even lead to the growth of bacteria, ultimately resulting in financial losses for businesses. Ensuring optimal temperature control during the transportation of temperature-sensitive goods is crucial.

A temperature-controlled container monitoring system provides a proactive solution to mitigate the risks associated with temperature variations during transit. It utilizes a network of smart sensors embedded within containers to continuously monitor and supervise the environment. By using real-time data, this system can provide early warnings and alerts, allowing for timely interventions to maintain the desired temperature range.

The cloud-based analytics platform of this monitoring system enables the remote management and optimization of temperature control. It offers a secure web-based interface for accessing and analyzing the collected data. Through predictive analytics, it can identify patterns and trends, facilitating proactive maintenance and minimizing the risk of temperature deviations.

With the help of this temperature-controlled container monitoring system, businesses can ensure the reliability and accuracy of their refrigeration units. The intelligent sensors provide visibility into the operational status of the containers, allowing for prompt maintenance and repairs. By streamlining the supply chain and optimizing the temperature control, this system enhances the overall management of stock and reduces the likelihood of temperature-sensitive goods getting damaged or spoiled.

Overall, the implementation of a temperature-controlled container monitoring system brings numerous benefits to businesses. It enables proactive monitoring, early warning alerts, and analytics-based optimization. By ensuring the ideal temperature conditions for sensitive shipments, businesses can protect their goods, reduce financial losses, and maintain customer satisfaction.

Temperature control is a critical factor in ensuring the quality and shelf life of products during transportation and storage. Improper temperature and humidity conditions can lead to spoilage, degradation, and even complete loss of goods. This is particularly crucial in sensitive industries such as food and pharmaceuticals, where temperature fluctuations can render products unsafe for consumption or ineffective.

To address this challenge, the implementation of a temperature-controlled container monitoring system becomes essential. This system, enabled by digitalization and automation, allows for the optimization of operational efficiency in shipments. By integrating smart logistics and fleet management technologies, it provides reliable and efficient monitoring of temperature and humidity conditions throughout the entire logistic process.

The temperature-controlled container monitoring system employs advanced sensors and devices that enable real-time tracking and storage of temperature data. This data is then analyzed through web-based analytics, providing visibility and transparency into the condition of goods. With automated alerts and notifications, early warning signs of temperature deviations can be identified, allowing for immediate corrective actions.

The system’s wireless connectivity and integration capabilities ensure traceability and reliability in cold chain logistics. With comprehensive and accurate data, logistics operators can identify areas for improvement and streamline their processes to enhance efficiency. This results in better stock management, reduced waste, and improved customer satisfaction.

In conclusion, a temperature-controlled container monitoring system is a vital tool for organizations that rely on the transportation and storage of temperature-sensitive goods. By leveraging advanced technologies and analytics, it offers a comprehensive solution to ensure the optimal temperature control and quality of products, while also improving the overall efficiency and transparency of the logistic operations.

Reefer monitoring systems play a vital role in ensuring optimal temperature control in temperature-controlled containers. These systems are designed to store,monitor, and track the temperature and environmental conditions inside the containers, providing real-time monitoring and early warning of any deviations from the desired temperature range.

Reefer monitoring solutions utilize advanced technology, such as IoT devices, to remotely monitor and control the refrigeration units in the containers. This allows for efficient fleet maintenance and performance optimization, as well as transparency and compliance with regulatory requirements.

By using cloud-based platforms, reefer monitoring systems offer a streamlined approach to reefer supervision. Through the measurement and analysis of data, these systems provide predictive insights and traceability of stock and goods throughout the supply chain.

The main goal of a reefer monitoring system is to ensure cold chain efficiency and reliability. It helps businesses maintain the quality and safety of temperature-sensitive goods during storage and transportation, reducing the risk of spoilage or damage.

Overall, reefer monitoring systems provide a sustainable and efficient solution for temperature-controlled storage and logistics. With their advanced capabilities and real-time monitoring, businesses can have better control over their reefer fleets, improve compliance, and ultimately enhance the overall performance of their supply chain.

A reefer monitoring system is a state-of-the-art technology that enables the safe and reliable transportation of temperature-sensitive goods. It consists of wireless temperature sensors that are strategically placed inside temperature-controlled containers, allowing for real-time monitoring of the conditions inside. This proactive approach ensures that the containers maintain the desired temperature throughout the entire shipment, minimizing the risk of spoilage and ensuring product quality and safety.

The temperature-controlled container monitoring system utilizes predictive analysis solutions to streamline performance and enhance efficiency in the logistic process. By integrating with the existing fleet management system, it provides transparency and allows for remote monitoring of multiple containers simultaneously. This digitalization of the process not only saves time but also reduces human error, as it eliminates the need for manual temperature checks and data entry.

In addition to monitoring temperature, the reefer monitoring system also tracks humidity levels, compliance with environmental regulations, and early warning alerts of any potential deviations from the optimal conditions. This comprehensive monitoring ensures that the goods are always transported in the best possible environment, minimizing the risk of bacteria growth, spoilage, or contamination. With its high accuracy and reliability, the system guarantees that the products reach their destination in the same condition as when they were shipped.

The reefer monitoring system is a cost-effective solution that not only saves on potential losses due to spoiled stock but also reduces energy consumption. By maintaining a constant temperature and optimizing the refrigeration process, it ensures efficient use of resources. The streamlined monitoring and alert system enable quick response and intervention, minimizing any potential disruptions in the supply chain.

In conclusion, a reefer monitoring system is an essential tool for businesses involved in temperature-controlled shipments. By providing real-time monitoring, predictive analysis, and early warning alerts, it ensures the safety, quality, and efficiency of the transportation process. With its advanced technology and accurate tracking, it simplifies logistic operations and guarantees that the products are delivered in optimal conditions.

A reefer monitoring system is a highly specialized and advanced solution that ensures optimal temperature control in temperature-controlled containers or reefers. This system consists of several key components and offers a range of functionalities to ensure the safe and efficient transportation of perishable goods.

In conclusion, a reefer monitoring system is a sophisticated and indispensable tool for businesses in the transportation and logistics industry. It provides a streamlined and cost-effective solution for managing and controlling temperature-sensitive goods, while also offering traceability, early warning capabilities, and environmental sustainability.

A reefer monitoring system offers numerous benefits for supply chain logistic management, particularly in temperature-controlled containers. By implementing such a system, companies can achieve cost savings and increased reliability in their operations.

One of the key advantages of a reefer monitoring system is its ability to provide real-time temperature monitoring. By utilizing sensors and web-based technology, companies can securely monitor the temperature of their containers throughout the entire supply chain. This ensures that perishable goods are stored at the optimal temperature, reducing the risk of spoilage and bacterial growth.

A reefer monitoring system provides intelligent data analysis, allowing companies to track and analyze temperature data to identify trends and potential issues. By using analytics and reporting tools, companies can make proactive decisions to optimize their cold chain management and reduce costs associated with spoilage or non-compliance.

The system also provides real-time alerts and notifications to key stakeholders when temperature conditions deviate from the set parameters. This allows companies to take immediate action to rectify any issues and ensure the quality of the goods being transported.

By implementing a reefer monitoring system, companies can save costs associated with the disposal of spoiled goods and non-compliance fines. Additionally, the system provides insights into equipment maintenance needs, allowing companies to schedule maintenance proactively and avoid unexpected breakdowns.

In conclusion, a reefer monitoring system is a cost-effective and intelligent solution for temperature-controlled container monitoring. With real-time temperature monitoring, proactive alerts, and comprehensive data analysis, companies can achieve greater reliability, cost savings, and improved overall management of their cold chain.

Transporting sensitive goods, such as pharmaceuticals or perishable food, requires a reliable and cost-effective solution to maintain the required temperature. Implementing a temperature-controlled container monitoring system provides enhanced visibility and security during transportation, ensuring the optimal performance of reefer containers.

The system utilizes a module that is securely connected to the container, allowing real-time monitoring and traceability of temperature conditions. By leveraging cloud-based technology, the system provides remote access to temperature data, enabling proactive management and alerting when deviations occur. Moreover, the integration with fleet management platforms streamlines the process and enhances compliance with temperature-controlled regulations.

The monitoring system ensures accuracy in temperature measurement, allowing the optimization of the cold chain process. With web-based interfaces, stakeholders have access to comprehensive data reports that enable performance analysis, stock management, and cost savings. By automating the monitoring process, manual checks and potential errors are reduced, ensuring both the quality of goods and minimizing the risk of spoilage.

The refrigeration system within the containers can be controlled and adjusted remotely, ensuring the desired temperature is maintained throughout the storage and transportation process. This intelligent and sustainable solution not only enhances the reliability of temperature-controlled containers but also contributes to a more efficient and environmentally friendly cold chain.

In the world of logistics, the cost of product losses due to temperature fluctuations in containers can have a significant financial impact on businesses. That’s why investing in a connected and streamlined temperature-controlled container monitoring system is crucial. With a wireless and web-based system, businesses can ensure optimal temperature conditions for sensitive products, improving efficiency and reducing losses.

The system utilizes advanced performance analytics to monitor and analyze temperature data, providing real-time insights into the container’s environment. This data-driven approach allows for better logistics supervision, enabling businesses to make data-backed decisions in managing their supply chain.

By using an automated temperature monitoring system, businesses can streamline their operations and improve traceability. The system provides reliable early warning alerts, ensuring that any deviations from the desired temperature are detected promptly. This level of visibility allows businesses to take immediate action, preventing potential product losses.

The container monitoring system also contributes to sustainable practices. With efficient temperature management, businesses can reduce energy consumption and minimize their environmental impact. This helps create a more sustainable and responsible supply chain.

In summary, investing in a cost-effective and data-driven temperature-controlled container monitoring system is essential for businesses looking to reduce product losses and financial impact. The system’s reliability, early warning alerts, and performance analytics provide businesses with the necessary tools to ensure optimal temperature conditions and streamline their operations. This ultimately leads to improved efficiency, reduced losses, and a more sustainable supply chain.

To ensure the safe and efficient transportation of temperature-sensitive goods, compliance with industry regulations and standards is crucial. Implementing a temperature-controlled container monitoring system allows companies to proactively monitor and manage the conditions of their shipments. By utilizing sensors and integrated IoT technology, this system provides real-time data on temperature, humidity, and pressure within the container.

By having access to this information, companies can take proactive measures to maintain optimal conditions for their goods. In the event of any deviations from the desired parameters, the system can send notifications and alerts to the relevant personnel, allowing them to take immediate action. This level of automation and intelligent monitoring ensures that goods are stored and transported in compliance with regulatory requirements, reducing the risk of spoilage and ensuring customer satisfaction.

Integrated with a web-based module, this cold chain monitoring system allows for efficient analysis and maintenance of data. The system provides various metrics and analytics, giving companies insights into the performance of their supply chain. This information can be used to identify areas for improvement, optimize operational processes, and reduce costs.

Furthermore, the system’s cloud-based technology enables transparency and collaboration throughout the entire logistic process. Stakeholders, including manufacturers, suppliers, and customers, can access real-time information on the status and location of the shipment. This transparency facilitates effective communication and enables timely decision-making.

By digitalizing the monitoring and compliance process, companies can streamline their operations and achieve cost-effective management of their cold chain. With an automated and intelligent system in place, companies can ensure the integrity and quality of their temperature-sensitive goods, maintaining customer satisfaction and enhancing their competitive edge in the market.

A reefer monitoring system is an intelligent operational system that helps monitor and control the conditions inside temperature-controlled containers, ensuring the optimal environment for sensitive cargo. These systems use a combination of sensors, telematics, and digitalization to provide efficient monitoring and reporting.

The system includes various sensors that track the temperature, humidity, and other environmental parameters inside the container. These sensors provide accurate and real-time data, allowing for early warning and timely management of any deviations from the desired conditions.

Connected to the reefer refrigeration unit, the monitoring system enables efficient control over temperature and ensures that the cargo is kept within the required range. This digital supervision helps maintain the integrity of the cold chain and prevents temperature fluctuations that can compromise the quality of the cargo.

The data collected by the monitoring system is accessible through a central platform, providing visibility and control over the entire fleet of containers in the supply chain. Through data analysis, the system can identify patterns and trends, allowing for continuous improvement and increased efficiency in the transport and storage of sensitive cargo.

In addition to temperature monitoring, the reefer monitoring system can also track the performance of the refrigeration unit, ensuring its optimal operation. This includes monitoring energy consumption, humidity levels, and the presence of bacteria, further enhancing the quality and safety of the cargo.

Overall, a reefer monitoring system is an essential tool in the temperature-controlled container industry, providing accurate and efficient monitoring, control, and reporting of the container’s environmental conditions. By ensuring the optimal temperature and environmental conditions, these systems help maintain the quality and integrity of the cargo throughout the entire supply chain.

Efficient temperature control is vital when it comes to transporting temperature-sensitive goods in the logistics industry. Using a network of connected sensors, a temperature-controlled container monitoring system ensures the optimal condition of the cargo. These wireless devices, integrated with IoT technology, provide accurate measurement and real-time monitoring of the temperature and humidity inside the container.

The web-based dashboard of the monitoring system allows for easy access to the data collected by the sensors. With this data, logistic businesses can analyze and track the condition of their stock, ensuring the traceability and reliability of the goods. By keeping the temperature within the required range, these systems help prevent the growth of bacteria and maintain the quality of the cargo.

Automated data analysis and maintenance alerts provided by the monitoring system make it a cost-effective and efficient solution for temperature-controlled transport. The system can generate automated reports and send notifications in case of any temperature discrepancies or anomalies, allowing for prompt action to be taken to secure the cargo.

By using intelligent sensors and advanced technology, the temperature-controlled container monitoring system optimizes the efficiency of the logistic process. It helps in reducing the risk of spoilage, ensuring the safe transportation of chilled goods, and minimizing the overall cost of maintenance. With the integration of automated metrics and real-time data analysis, fleet managers can have full visibility and control over their reefer containers, enhancing the sustainability and reliability of their supply chain.

In conclusion, the use of a temperature-controlled container monitoring system with integrated sensors and IoT technology provides accurate and reliable data regarding the condition of the cargo. This enables the logistics industry to ensure the optimal temperature control of their containers, preventing spoilage, and maintaining the quality of the goods. Through automated data analysis and maintenance alerts, the system enhances efficiency and cost-effectiveness, while also enhancing traceability and sustainable practices.

With the advancement in telematics and IoT technology, businesses can now ensure optimal temperature control in their containers through automated monitoring systems. These systems provide real-time data transmission and remote access, allowing for efficient control and management of temperature-sensitive goods throughout the supply chain.

By utilizing sensors and connected devices, these systems continuously monitor the environment inside the container and send alerts in case of any deviation from the desired temperature range. This proactive approach enables early warning and timely intervention to prevent any potential damage to the goods.

The integration of advanced automation and refrigeration equipment ensures accurate temperature control, resulting in improved reliability and traceability of the supply chain. The streamlined monitoring process eliminates the need for manual temperature checks and reduces the risk of human error.

The data collected by the monitoring system is transmitted in real-time to a web-based dashboard, providing an accurate and up-to-date view of the container’s temperature condition. This allows for remote access and monitoring of multiple containers simultaneously, saving time and resources.

By implementing a temperature-controlled container monitoring system, businesses can optimize their supply chain operations by ensuring the efficient and safe transportation of chilled goods. The automated solutions enable accurate and reliable temperature control, minimizing the risk of spoilage and ensuring customer satisfaction.

In conclusion, real-time data transmission and remote access provided by temperature-controlled container monitoring systems enhance the efficiency and accuracy of logistics. By integrating advanced automation and sensors, businesses can proactively monitor and control the temperature inside containers, ensuring the safe transportation of temperature-sensitive goods.

Real-time data transmission refers to the process of sending data or information over a network or communication channel instantaneously, without any delay.

Remote access allows users to connect and access a computer system or network from a distant location, using a network or internet connection.

Some of the benefits of real-time data transmission include instant communication, faster decision-making, improved productivity, and better customer service.

Remote access offers advantages such as flexibility for employees to work from anywhere, increased efficiency and productivity, cost savings, and the ability to access files and resources on the go.

Technologies used for real-time data transmission include internet protocols like TCP/IP, streaming protocols, data compression techniques, and high-speed networks like Ethernet or fiber optics.

Remote access can be secure with proper implementation of security measures such as strong authentication, encryption, firewalls, and regular updates and patches to prevent unauthorized access and protect sensitive data.