Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

Container fleet management plays a critical role in the smooth running of supply chains, ensuring the timely and efficient movement of goods. However, manual tracking and management of container fleets can be a time-consuming and error-prone process. To overcome these challenges, advanced systems and technologies offer actionable insights to enhance productivity, safety, and decision-making.

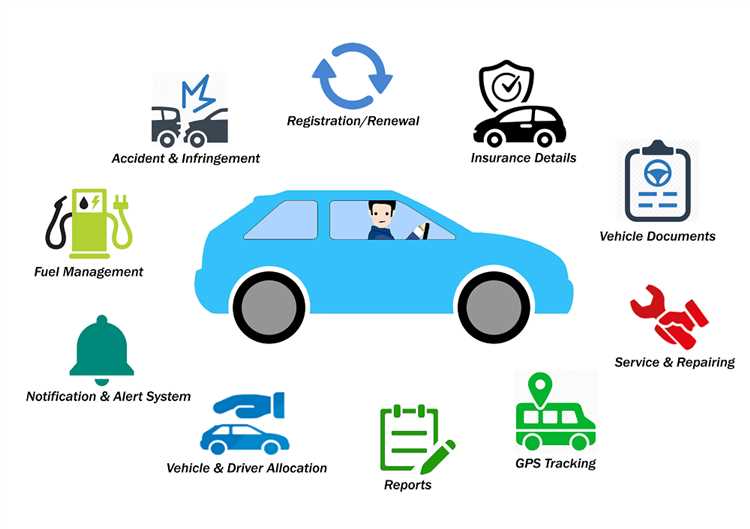

One such technology is telematics, which provides real-time monitoring and positioning of containers and vehicles. With telematics, fleet managers can track the movement, location, and status of containers, enabling efficient allocation and utilization of assets. This data can also be integrated into a centralized database, providing a comprehensive overview of the container fleet for informed decision-making.

Predictive analytics is another powerful tool that can optimize container fleet management. By analyzing historical data and forecasting future demands, fleet managers can make proactive decisions on procurement, maintenance, and warehousing. This can lead to cost minimization, improved operational efficiency, and timely shipment of goods to customers.

In addition, advanced systems can provide alerts and notifications for various aspects of fleet management, such as maintenance schedules, compliance with customs and security regulations, and inspection requirements. These alerts help fleet managers stay on top of critical tasks and ensure the safety and security of cargo and crew.

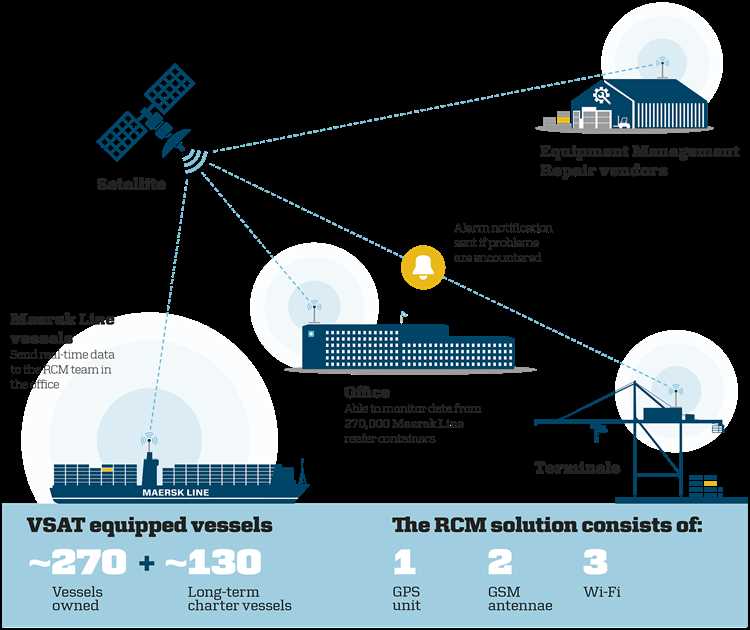

Furthermore, end-to-end solutions, including IoT-enabled devices, provide real-time visibility into the entire supply chain, from the port of loading to the final destination. This enables effective coordination and optimization of operations, reducing demurrage and transportation costs. Integrated systems also enable easier collaboration and communication between stakeholders, including port authorities, shipping lines, rail operators, and logistics providers.

In conclusion, advanced systems and technologies offer significant improvements in container fleet management. From real-time monitoring and predictive analytics to centralized databases and end-to-end solutions, these tools enhance efficiency, safety, and decision-making. By adopting these technologies, businesses can optimize their container fleet operations and stay ahead in today’s competitive market.

Container fleet management plays a vital role in the smooth operation of intermodal logistics. However, traditional methods often fall short in terms of efficiency and utilization. To overcome these challenges, businesses are now turning to advanced systems that leverage the power of the internet and cutting-edge technology.

One key component of these systems is enhanced visibility. By utilizing real-time tracking and inventory status, businesses can have a comprehensive view of their entire fleet. This allows for better decision-making regarding routing, trailer utilization, and driver dispatching. With a centralized database, dispatchers can easily access information on demand and make actionable decisions to optimize routes and minimize downtime.

Another important aspect of advanced systems is improved communication. By providing drivers with innovative interfaces and mobile applications, businesses can streamline communication and ensure effective coordination between drivers, dispatchers, and other stakeholders. Real-time updates on container status and inspection results enable quick response to any issues, reducing demurrage costs and improving overall efficiency.

Additionally, advanced systems offer powerful analytics capabilities. Through data analysis, businesses can gain valuable insights into their container fleet operations. By forecasting demand, optimizing lease and rental agreements, and analyzing historical data, businesses can make informed decisions that increase efficiency and minimize costs.

Overall, the introduction of advanced systems in container fleet management brings numerous benefits to businesses. From improved visibility and communication to enhanced analysis and forecasting, these systems enable businesses to optimize their operations and stay ahead in the competitive logistics industry.

The use of advanced systems in container fleet management offers numerous benefits for businesses in terms of efficiency, cost savings, and overall performance improvement. These systems provide a comprehensive solution for route planning, operations management, and real-time monitoring of container fleets.

In conclusion, the use of advanced systems in container fleet management provides significant benefits for businesses, including improved operations, enhanced visibility, increased security, cost reduction, and actionable insights. By leveraging these systems, businesses can streamline their processes, make informed decisions, and optimize their container fleet management operations.

Managing a fleet of containers is a complex task that requires efficient utilization of assets and effective communication between vehicles, vessels, and hubs. With the advancement of IoT technology, businesses can now optimize container utilization through insights gained from data collected from various sources.

By integrating IoT devices into containers and other equipment, companies can monitor their condition in real time and receive alerts for any potential issues. This predictive maintenance approach saves businesses time and money by preventing costly repairs and reducing downtime.

Advanced systems also enable businesses to optimize container routing and dispatching, ensuring that cargo is delivered in the most efficient and cost-effective way. With the help of GPS and other tracking technologies, companies can create user-friendly interfaces and mobile applications for real-time monitoring of shipments.

In addition to optimizing container usage, advanced systems can also improve productivity and efficiency in warehousing and analysis. By automating processes such as inspection, repair, and customs clearance, businesses can streamline their operations and reduce costs. Furthermore, data analytics and reporting tools provide valuable insights for supply chain planning and operational decision-making.

Overall, the integration of advanced systems in container fleet management offers businesses the opportunity to optimize asset utilization, minimize fuel consumption, and improve customer satisfaction. With improved communication and automation, businesses can achieve higher productivity and reduce the risk of human error. These advancements in containerization technology are revolutionizing the industry and paving the way for future innovations.

In today’s fast-paced shipping industry, real-time tracking and monitoring of containers has become an essential component of effective container fleet management. With advanced systems and technology, companies are able to efficiently track and monitor their container inventory, ensuring optimal performance and improved efficiency in container allocation and routing.

By implementing a real-time tracking and monitoring system, companies can gain valuable insights into the location and status of their containers. This allows for better planning and optimization of routes, as well as the ability to quickly and accurately allocate containers to specific shipments. With real-time data, dispatchers can make informed decisions to minimize downtime, reduce demurrage and detention costs, and optimize the overall performance of their container fleet.

The use of Internet of Things (IoT) technology has significantly enhanced container tracking capabilities. By equipping containers with IoT devices, companies can collect and analyze data on factors such as temperature, humidity, and shock levels. This enables them to ensure proper temperature control for sensitive cargo, reduce the risk of damage to goods during transportation, and provide customers with real-time visibility into the status of their shipments.

In addition to real-time tracking, advanced systems also offer historical data analysis and forecasting capabilities. By analyzing past performance data, companies can identify trends and patterns, which can be used to improve future operational efficiency and optimize resource allocation. This can lead to significant cost savings in areas such as container purchase, maintenance, and inventory management.

Furthermore, real-time tracking and monitoring systems provide enhanced visibility throughout the containerization process. From the warehouse to the port, and from the port to the final destination, companies can easily track the movement of their containers and ensure that they are being efficiently managed and utilized. This level of visibility allows for better coordination with stakeholders, including truck drivers, warehouse operators, and depot managers, resulting in smoother operations and improved customer satisfaction.

Overall, implementing a real-time tracking and monitoring system for containers is essential for companies looking to optimize their container fleet management. By leveraging advanced technology and data intelligence, companies can improve routing and allocation decisions, minimize downtime and costs, and enhance overall operational efficiency. With real-time insights and predictive analytics, companies can stay one step ahead in the competitive shipping industry.

Container theft is a significant concern in the transportation industry, leading to financial losses, delays, and potential safety hazards. However, by implementing advanced systems and technologies, such as Internet of Things (IoT) and real-time tracking, security can be improved and container theft can be prevented.

One way to enhance security is through the use of IoT devices, which enable real-time monitoring and tracking of containers. These devices can be installed on containers, barges, vehicles, and other equipment, providing continuous updates on their status and positioning. This information can be accessed through a user-friendly interface, allowing for efficient inventory management and control.

By integrating predictive analysis and intelligence into the system, potential security threats can be identified in advance. Through historical data and analysis, patterns of theft can be recognized, enabling proactive measures to be taken. Additionally, alerts and notifications can be set up to automatically notify relevant personnel in case of any suspicious activities or breaches.

Furthermore, efficient loading, unloading, and allocation of containers can contribute to improved security. By optimizing the scheduling and control of container transportation, the risk of theft is minimized. Automated systems can provide accurate information on container locations and facilitate seamless collaboration between different stakeholders, such as ports, rail operators, intermodal providers, and brokerage firms.

Another aspect of security improvement is ensuring compliance with regulations and standards. Advanced systems can offer real-time reporting and documentation to meet the requirements of authorities and customers. This includes maintaining accurate records of container shipments, equipment lease, rental, and purchase, as well as minimizing any potential discrepancies or errors.

Overall, implementing an advanced security solution can not only prevent container theft but also enhance fleet management efficiency, cost savings, and operational control. With real-time monitoring, predictive analysis, and comprehensive reporting, the risk of theft can be mitigated, and the overall security of container transportation can be significantly improved.

In the competitive business of container fleet management, an efficient process for maintenance and repair is crucial for optimizing shipment operations. By streamlining maintenance and repair processes, companies can improve the overall performance of their vehicle fleet, resulting in cost savings and increased customer satisfaction.

Implementing advanced systems, such as IoT and telematics technology, allows for automated monitoring of the status and condition of vehicles. Real-time data on fuel consumption, compliance with regulations, and historical maintenance records can be collected and analyzed, enabling more informed decision-making for maintenance and repair tasks.

By leveraging telematics, companies can also track the location and status of containers throughout the transportation chain. This helps to minimize delays and optimize loading and unloading procedures at ports, warehouses, and distribution hubs. Furthermore, the automation of document clearance processes and customs duties ensures a smoother workflow and faster turnaround times.

In addition to vehicle and container monitoring, advanced systems can also enhance maintenance and repair processes for essential assets such as cranes, chassis, and other machinery used in the transportation and warehousing industry. Predictive maintenance tools can help to detect potential issues before they become critical, reducing downtime and minimizing costs associated with repairs.

Furthermore, by implementing IoT technology, companies can improve the efficiency of their rental and leasing operations. Real-time data on vehicle availability, utilization, and maintenance requirements enables better planning and utilization of resources.

Overall, streamlining maintenance and repair processes through the use of advanced systems and technology has significant benefits for container fleet management. It improves decision-making, enhances customer satisfaction, reduces costs, and optimizes the overall supply chain. By leveraging the power of the Internet of Things and telematics, companies can achieve greater efficiency and success in the business of container fleet management.

Efficiency in container handling and operations is crucial for the smooth functioning of shipping ports and logistics hubs. By implementing advanced solutions and leveraging technology, organizations can improve their workflow, optimize resource utilization, and enhance overall efficiency in their container fleet management.

One of the key factors in achieving efficiency is data management. By collecting and analyzing relevant data, organizations can gain valuable insights into their container fleet’s status, utilization, and historical performance. This data can be utilized to identify inefficiencies and make informed decisions to improve operations and minimize costs.

Advanced systems, such as IoT-enabled monitoring platforms and real-time communication tools, enable organizations to have better visibility and control over their container fleet. These systems provide actionable information on container positioning, route planning, and maintenance needs. They also facilitate efficient communication between stakeholders, such as shipping lines, customs brokerage, and warehousing, ensuring smooth coordination and minimized delays.

Another area where efficiency can be enhanced is container handling. The deployment of automated cranes and advanced yard management systems improves the speed and accuracy of container positioning and minimizes detention times. These systems enable organizations to streamline their container operations, reduce idle time, and improve overall productivity.

Efficiency can also be improved through effective fleet management. By using advanced decision-making dashboards, organizations can monitor and optimize their container fleet’s utilization and performance. This includes tracking rental container usage, managing chassis inventory, and scheduling maintenance activities. By effectively managing these aspects, organizations can minimize downtime, increase asset utilization, and achieve significant cost savings.

In conclusion, enhancing efficiency in container handling and operations requires a holistic approach, integrating advanced systems, data management, and effective fleet management. By implementing solutions that improve visibility, streamline communication, and optimize resource utilization, organizations can achieve higher levels of efficiency in their container fleet management, leading to cost savings and improved customer satisfaction.

Effective container fleet management requires accurate forecasting and demand planning. Advanced systems can significantly improve efficiency and productivity in this area.

One key component of these advanced systems is real-time tracking and inventory management. With the help of IoT technology, containers can be tracked and their condition monitored in real-time. This allows businesses to optimize routing and scheduling, reducing costs and improving asset utilization.

Another important aspect is the use of data analysis and automated solutions. By analyzing historical data and trends, businesses can better predict demand and make informed decisions regarding purchase, clearance, rental, repair, and maintenance of containers. By automating these processes, businesses can save time and resources, improving overall efficiency.

Furthermore, advanced systems enable businesses to optimize warehouse and yard management. By accurately tracking the location of containers and using advanced routing algorithms, businesses can streamline operations and reduce unnecessary tasks. This improves productivity and ensures smooth operations, even during peak seasons.

Advanced systems also empower businesses to enhance security measures and reduce the risk of theft or damage to containers. By implementing advanced tracking and monitoring solutions, businesses can ensure the safety of their assets and provide peace of mind to their clients.

In addition, these systems can help businesses forecast and optimize fuel consumption, reducing costs and minimizing environmental impact. By analyzing data on transportation routes and container conditions, businesses can make informed decisions regarding fuel usage and implement measures to improve fuel efficiency.

In summary, advanced systems for forecasting and demand planning offer a range of benefits to businesses. They improve container fleet management by providing real-time tracking, automated analysis, and optimized routing. These systems also enhance security, reduce costs, and improve overall efficiency. By investing in these advanced systems, businesses can optimize their container fleet management, leading to increased productivity and improved customer satisfaction.

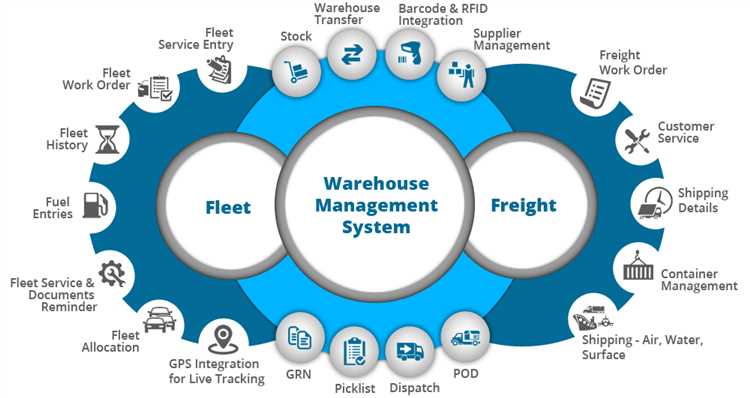

Integrating container fleet management systems with other business functions is crucial for efficient operations in the supply chain. A terminal or port, for example, can benefit from integrating fleet management systems with their warehouse operation, dispatching, and clearance processes. By streamlining these functions, they can improve productivity, reduce costs, and optimize container movement.

One area where integration can be particularly beneficial is in the automation of the procurement process. By integrating fleet management systems with procurement platforms, companies can automate the lease or purchase of containerized vehicles. This not only improves efficiency but also provides visibility into historical data for better forecasting and cost savings.

Predictive analytics and alerts modules are another key integration point. By integrating fleet management systems with analytics platforms, companies can gain real-time insights and intelligence into their fleet’s performance. This enables dispatchers to optimize routes, minimize repair and maintenance costs, and improve overall fleet efficiency.

Integrating fleet management systems with cooling systems can also be valuable. By monitoring temperature and humidity in containers, companies can ensure the safe transportation of temperature-sensitive cargo. This integration provides better visibility and control over the condition of the cargo, reducing the risk of damage and improving customer satisfaction.

Furthermore, integrating fleet management systems with document management and brokerage platforms can streamline the clearance process. By automating document processing and improving communication between different stakeholders, companies can reduce clearance time and improve operational efficiency.

In conclusion, integrating container fleet management systems with other business functions brings numerous benefits to companies in terms of efficiency, cost savings, and visibility. By optimizing operations and leveraging historical data, companies can make better-informed decisions, improve customer satisfaction, and gain a competitive edge in the market.

Advanced operational systems can greatly improve customer satisfaction in the container fleet management industry. With the help of these systems, dispatchers can efficiently track and manage shipments, ensuring timely delivery and reducing potential delays. The use of automated inspection technology and warehouse management systems allows for quicker and more accurate handling of goods, minimizing damage and improving overall customer satisfaction.

One key feature of advanced systems is the use of user-friendly web portals and interfaces that provide customers with real-time visibility into the status of their shipments. Customers can easily access information about their goods, such as location, temperature, and condition, through a secure online portal. This level of transparency enhances customer trust and satisfaction, as they have greater control and visibility over their assets throughout the transportation process.

Furthermore, advanced systems can help reduce costs and improve efficiency for both customers and fleet management companies. Through the use of data analysis and route optimization modules, these systems can determine the most cost-effective and efficient routes for vehicles. This not only reduces transportation costs but also minimizes fuel consumption and emissions, promoting sustainability and environmental awareness.

Another area where advanced systems excel is inventory management. By providing real-time inventory tracking and asset management, these systems enable companies to have better control over their stock and ensure a higher level of accuracy in stock-taking. This leads to improved order fulfillment and reduces the risk of stock-outs or overstock situations, enhancing customer satisfaction and loyalty.

Additionally, advanced systems facilitate seamless communication between different entities involved in the container fleet management process. The use of Internet of Things (IoT) technology enables constant communication and coordination between vehicles, warehouse, and depot, ensuring smooth operations and minimizing bottlenecks. This level of connectivity and real-time visibility allows for better decision-making and problem-solving, ultimately leading to higher customer satisfaction.

In conclusion, the implementation of advanced systems in container fleet management can greatly enhance customer satisfaction. From improved visibility and control to cost reductions and better inventory management, these systems provide a holistic solution that benefits both customers and fleet management companies. By investing in these systems, companies can ensure higher customer satisfaction, leading to increased customer retention and business growth.

Advanced container fleet management systems offer a wide range of cost-saving benefits and a significant return on investment for businesses in the shipping industry. These innovative applications leverage cutting-edge technology to optimize various aspects of container fleet operations, resulting in reduced costs and improved efficiency.

One area where cost savings can be achieved is in route optimization. Advanced systems use real-time data and analytics to identify the most efficient routes for container vessels, reducing fuel consumption and overall transportation costs. This optimization also minimizes the risk of delays and ensures timely delivery of goods to customers.

Another cost-saving factor is the reduction in maintenance and repair expenses. Through IoT-enabled tracking and monitoring, these solutions provide real-time insights into container conditions, allowing for preventive maintenance and timely repairs. This proactive approach eliminates the need for costly emergency repairs and extends the lifespan of containers.

Furthermore, the use of advanced fleet management systems enables better allocation of resources. These systems streamline the workflow by automating processes, such as container inspection, equipment rental, and crew duties allocation. By optimizing the utilization of assets and personnel, businesses can reduce labor costs and increase overall productivity.

Additionally, these systems provide end-to-end visibility and improve communication throughout the container fleet management process. Through user-friendly portals and mobile applications, stakeholders can easily access real-time information on container positioning, inventory, and performance. This enhanced visibility and communication facilitate better decision-making, leading to more efficient operations and cost savings.

Moreover, advanced container fleet management systems offer optimization opportunities in warehouse and depot management. By utilizing IoT technology, these systems enable efficient inventory management, reducing stock discrepancies and minimizing storage costs. They also facilitate streamlined processes for container detention and chassis duties, further enhancing cost savings.

In summary, by leveraging advanced container fleet management systems, businesses in the shipping industry can achieve significant cost savings and a high return on investment. These innovative solutions optimize various aspects of fleet operations, including route planning, maintenance, resource allocation, and communication, resulting in reduced expenses and improved efficiency. With the ever-increasing demands of the shipping business, investing in these advanced systems is crucial for staying competitive in the market.

An advanced container fleet management system is a software solution that helps companies efficiently manage and track their shipping containers. It provides real-time visibility into container location, condition, and status, as well as automates processes such as scheduling, maintenance, and billing.

An advanced container fleet management system can help companies save costs in several ways. It allows for better utilization of containers, reducing the need for additional containers. It also enables more accurate forecasting and demand planning, which can lead to lower inventory costs. Additionally, the system automates processes and reduces manual errors, saving time and reducing operational costs.

The return on investment for implementing an advanced container fleet management system varies depending on the company and its specific needs. However, companies typically see a return on investment within 6-12 months. The system can help reduce operational costs, improve efficiency, and increase customer satisfaction, which ultimately leads to improved profitability.

An advanced container fleet management system typically includes features such as real-time container tracking, automated scheduling and maintenance, electronic document management, reporting and analytics, and integration with other systems such as ERP and CRM. These features help companies improve visibility, efficiency, and accuracy in managing their container fleet.

Real-time container tracking allows companies to have visibility into the exact location of their containers at any given time. This helps prevent loss or theft of containers, as well as provides accurate information to customers regarding the status of their shipments. Real-time tracking also helps optimize scheduling and routes, reducing transportation costs and improving overall operational efficiency.

Yes, an advanced container fleet management system can integrate with other business systems such as ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management). This integration allows for seamless data sharing and streamlines processes across different departments and systems. For example, container status and availability can be automatically updated in the ERP system, and customer information can be synchronized between the CRM and container management system.