Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

An ISO container, also known as an intermodal container, is a standardized metal box used for the transportation and storage of goods. With its durable steel construction and corrosion-resistant properties, the ISO container is the backbone of the global shipping industry.

These containers are designed to withstand the rigors of transportation across various modes, including air, road, rail, and sea. They are versatile enough to be seamlessly transferred between different transport vehicles and can be easily loaded and unloaded using cranes, forklifts, or other appropriate equipment.

ISO containers come in several sizes and configurations, including standard dry containers, flat racks, and refrigerated containers (reefers). Each type of container has specific features and requirements to ensure the safe and efficient transportation of the cargo.

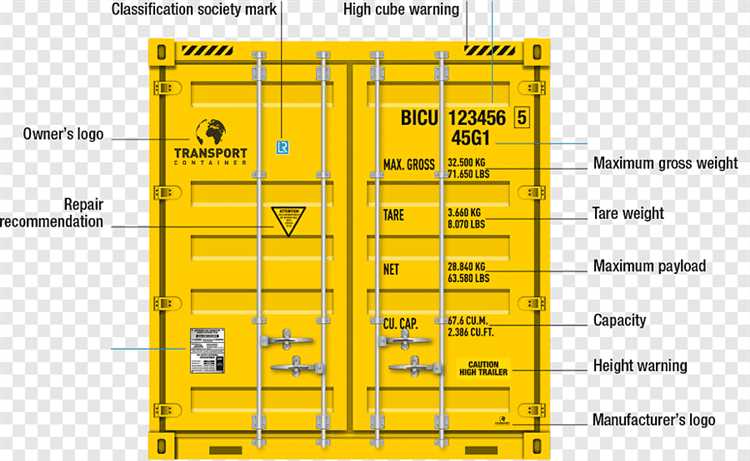

When it comes to shipping containers, proper handling, storage, and logistics are crucial. Containers need to be inspected for damage, leakage, or other issues before being loaded onto a ship or transferred to a warehouse. The containers must be properly labeled and marked for easy identification and documentation purposes.

During transportation, containers are secured with lashing and twist locks to prevent sway, vibration, and potential cargo damage. Special attention is given to handling dangerous goods, ensuring proper documentation, packaging, and adherence to relevant safety regulations. In the case of refrigerated containers, proper ventilation, reefer plug connection, and monitoring are essential to maintaining the desired temperature and humidity levels for perishable goods.

Shipping containers play a vital role in the global logistics network, facilitating the efficient movement of goods around the world. They enable goods to be transported from manufacturers to consumers through a complex chain of transportation and customs procedures. Each container is accompanied by a bill of lading, which serves as a legal document indicating ownership and detailing the cargo being transported.

Ultimately, ISO containers provide a cost-effective and secure means of transporting a wide range of goods, whether they are being transported across land, sea, or air. Their standardized design and construction ensure compatibility and ease of use within the shipping industry, making them the ultimate solution for international trade and commerce.

An ISO container, also known as a shipping container, is a standardized metal box used for transporting goods across the globe. It is designed to be easily transferable between different modes of transport, such as ships, trucks, and trains. These containers come in various sizes and configurations to accommodate different types of cargo.

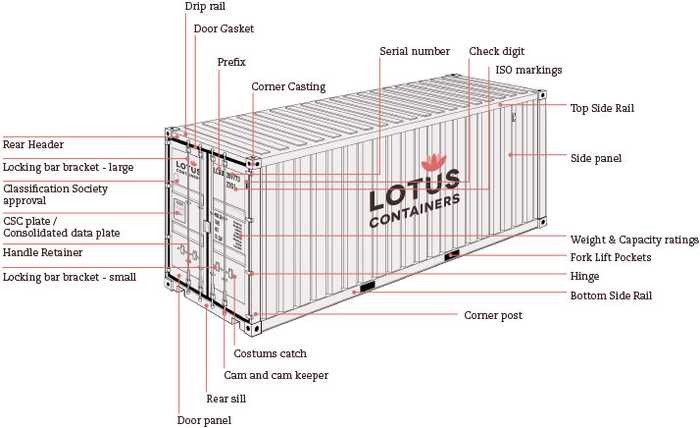

The construction of an ISO container includes strong steel walls, a reinforced floor, and corner fittings for hoisting and stacking. The container is equipped with multiple locking systems, including twistlocks, seals, and locks, to ensure the security of the cargo during transportation. It is also designed to withstand the rigors of rough handling, extreme weather conditions, and long-distance travel.

ISO containers are widely used in international trade for the shipment of goods. They can be easily loaded and unloaded at ports using cranes, forklifts, or other handling equipment. These containers can be stacked up to several levels high and secured together using wire ropes, chains, or twistlocks. This allows for efficient use of space on the vessel and minimizes the risk of cargo shifting or damage during transit.

ISO containers are available in different types, such as dry van containers, flat rack containers, and reefer containers. Dry van containers are the most common type, used for the transportation of general cargo. Flat rack containers are used for oversized or bulky cargo that cannot fit inside a standard container. Reefer containers are equipped with refrigeration units to transport goods that require controlled temperature.

Before being used for shipping, ISO containers undergo rigorous inspections and certifications to ensure their compliance with international standards. They are thoroughly checked for any damages, such as dents or corrosion, and tested for watertightness and proper functioning of doors and locks. The containers also need to meet specific labeling and documentation requirements for the identification and tracking of the shipment.

Once a container arrives at its destination port, it can be unloaded and transferred to a depot or warehouse for further distribution. In some cases, the container may need to be transported by trucking or drayage to its final destination. Demurrage charges may apply if the container is not returned within the agreed timeframe.

In conclusion, ISO containers play a crucial role in global trade, providing a secure and efficient means of shipping goods across different modes of transport. They are versatile, durable, and standardized, making them an indispensable tool for the transportation industry.

ISO containers have revolutionized the shipping industry by providing a standardized method for transporting goods internationally. The concept of using containers for shipping can be traced back to the early 20th century when various marking systems were developed to identify and consolidate cargo. However, it was not until the 1950s that the International Organization for Standardization (ISO) introduced the standardized shipping container that we are familiar with today.

The development of ISO containers introduced several key features that greatly improved the efficiency of transportation. One of these features is the corner casting, which allows containers to be easily stacked and secured during transport by rail, road, or sea. Additionally, the introduction of reefer plug technology enabled the transportation of perishable goods by providing temperature control to prevent freezing or spoilage.

ISO containers have played a crucial role in the expansion of the global logistics network. The use of containers has simplified the movement of goods by allowing for efficient loading and unloading, as well as easy transfer between different modes of transport. The inclusion of twist lock mechanisms ensures the secure connection of containers, while inspections guarantee compliance with safety standards.

Today, ISO containers are made from durable steel, ensuring their ability to withstand the demands of transport. They are used for shipping a wide range of products, including hazardous materials that require blast resistance and tanks for the transportation of liquids. Advanced technologies such as GPS tracking and air vents are also incorporated into containers to enhance safety and provide real-time monitoring of cargo.

In conclusion, the history of ISO containers is a testament to the ongoing evolution of the shipping industry. From humble beginnings to the widespread use of standardized containers, they have transformed the way goods are transported and stored. Whether for storage in a warehouse or transport on a chassis, ISO containers have become an integral part of global logistics and have greatly facilitated the movement of goods across borders.

ISO containers, also known as shipping containers, come in various types that cater to different cargo requirements. These containers provide a secure and efficient method for transporting goods across different modes of transportation, including ocean vessels, trucks, and trains. Let’s explore some of the most common types of ISO containers used in the shipping industry.

The standard container is the most widely used type, offering a versatile and cost-effective solution for transporting general cargo. It is equipped with sway-free lashing fittings, twist locks, and a lockable door to ensure safe and secure transportation.

Reefer containers are specifically designed for transporting goods that require temperature control, such as perishable food items or pharmaceuticals. They have built-in refrigeration units, air vents, and drip pans to prevent leakage and maintain the desired temperature.

Flat rack containers are ideal for oversized or heavy cargo that cannot be accommodated in a standard container. They have collapsible sides and end walls, allowing for easy loading and unloading using cranes or forklifts. They are also equipped with lashing points for securing the cargo.

Open top containers have a removable roof, making them suitable for cargo that cannot be loaded through standard container doors, such as machinery or large equipment. They are often used for transportation via crane or other lifting methods.

Tank containers are designed to transport hazardous or liquid goods, such as chemicals or fuels. They have specialized construction with acid resistance and moisture protection. The tanks can be easily loaded and unloaded using a hook or crane.

Flexitank containers are used for the transportation of non-hazardous liquids, such as wine or edible oils. They are lightweight, disposable, and can be easily loaded and unloaded using standard shipping equipment. Flexitanks provide a cost-effective alternative to traditional tank containers.

These are just a few examples of the various types of ISO containers available for shipping. The choice of container depends on factors such as the cargo type, size, and required transportation mode. Selecting the right container is crucial in ensuring the smooth and secure movement of goods throughout the supply chain, from the point of origin to the final destination.

ISO containers, also known as shipping containers, are standardized for international transportation. These containers are designed to be easily transported by various modes of transport, including trucking, rail, and vessel. The standard dimensions of ISO containers ensure compatibility and maneuverability during handling and storage.

The most common type of ISO container is the dry container, which is used for general cargo transportation. Dry containers have a standard 20ft or 40ft length, a width of 8ft, and a height of 8ft 6in. These dimensions allow for easy stacking and secure locking with twistlocks. The doors of dry containers have a width of 7ft 8in and a height of 7ft 6in, providing ample space for loading and unloading.

Reefer containers, used for transporting temperature-sensitive goods, have similar dimensions to dry containers but with the addition of refrigeration capabilities. These containers have a reefer socket and plug for power supply, as well as a drip pan to collect condensation. Reefer containers are certified to ensure they meet specific temperature and humidity requirements for the cargo being transported.

Specialized containers, such as flat racks and tank containers, have different dimensions to accommodate specific cargo types. Flat racks have collapsible or fixed end walls and no roof, allowing for easy loading and unloading of oversized or heavy cargo. Tank containers are designed to transport liquids or dangerous goods and have corrosion-resistant linings to protect the cargo. These containers are equipped with fittings for safe and secure transportation.

When shipping containers, proper documentation is essential. A bill of lading is issued by the shipping line, providing details about the shipment, such as the origin, destination, and contents. Seals and tamper-proof locks are used to secure the container during transit, while tracking devices, such as GPS, ensure real-time monitoring of the cargo. It is important to adhere to international shipping regulations and ensure all required certifications are obtained for the transportation of dangerous goods.

In conclusion, ISO containers come in standard dimensions to facilitate international shipping. These containers are versatile and can transport a wide range of cargo. Proper handling, storage, and documentation are crucial to ensuring the safe and efficient transport of goods. The shipping industry relies on these containers for the transportation of goods across the world, making them an essential component of global trade.

ISO Containers, also known as shipping containers, are constructed with specific features and certifications to ensure their suitability for global trade and transportation. These containers are designed to withstand various environmental conditions, such as corrosive materials, acid resistance, and blast resistance.

The construction of ISO Containers involves the use of steel, which provides strength and durability. The containers are built to specific size requirements, allowing them to be easily transported by road, rail, or ocean. They are fitted with air vents and air vents with drip pans to control temperature and ventilation. This ensures that the cargo inside is protected during the journey.

The certification process is crucial for ISO Containers. A certified container has been inspected and approved by authorized organizations, ensuring its compliance with international standards. This certification includes various aspects, such as leakages, lashing, labeling, and freeze tolerance. Containers that meet the certification requirements are labeled accordingly.

ISO Containers are commonly used for Full Container Load (FCL) shipments. They can be transported using trucking services for local transportation or placed in a shipping depot or terminal for international shipping. The containers can be loaded and unloaded using forklifts or cranes, depending on the size and weight of the cargo.

In addition, ISO Containers can be equipped with temperature control systems, known as reefers, to transport perishable goods or items that require specific temperature conditions. This allows for the safe transportation of goods that are sensitive to temperature changes.

Overall, the construction of ISO Containers plays a crucial role in global trade and logistics networks. These containers provide a reliable and efficient method of transporting goods across different modes of transportation, ensuring the safe and secure delivery of cargo to its destination. Customs clearance is also facilitated by the use of certified containers, streamlining the process of international trade.

ISO containers are designed to be easily transported across different modes of transportation, including ships, trucks, and trains. They can be seamlessly transferred between these modes without the need for unloading and reloading of cargo, saving time and reducing the risk of damage or loss.

ISO containers provide a high level of security for shipping goods. They are built with durable materials and equipped with robust locking mechanisms, such as twist locks, to prevent unauthorized access and tampering. This ensures the safety and integrity of the cargo throughout the entire supply chain.

ISO containers come in standardized sizes, such as 20-foot, 40-foot, and 45-foot, which allows for easy handling and stacking. This uniformity simplifies logistics and transportation planning, making it easier to load, unload, and stack containers both at the port and in storage facilities.

ISO containers can accommodate various types of cargo, including hazardous materials, bulk cargo, flatbed cargo, and temperature-sensitive goods. They can be modified with features like reefer plugs and sockets for temperature control, and markings for handling instructions to cater to different shipping requirements.

ISO containers are designed to withstand challenging environmental conditions, such as moisture, fungus, and acid. They offer excellent protection against vibration, sway, and stacking pressures during transportation. Additionally, they have blast resistance and can be equipped with tarpaulins for moisture protection.

Using ISO containers minimizes drayage and demurrage costs since they are compatible with standard shipping processes and equipment. They can be easily transferred between shipping companies, reducing time spent waiting for inspections or customs clearance. This improves overall efficiency in the shipping and logistics chain.

Transporting ISO containers is a complex process that involves various stages and methods to ensure safe and efficient shipping. From the terminal to the destination, several factors come into play.

Terminal: The journey begins at the terminal, where containers are organized and loaded onto trucks or rail cars for transportation.

Drayage: Drayage refers to the transportation of containers over a short distance, usually from the terminal to a nearby warehouse or distribution center. Trucking companies specialize in this task.

Shipping: Once loaded onto trucks or rail cars, the containers are shipped to their respective destinations. Leakage or hazardous materials are handled with utmost care and may require special handling equipment or additional safety measures.

Crane: At the destination, cranes are used to offload the containers from trucks or rail cars. These powerful machines carefully lift and place the containers onto the designated storage areas or loading docks.

Lock and Inspection: Containers are secured with locks and inspected for damages or potential issues during the transportation process. Seals are used to ensure the integrity of the containers and to prevent unauthorized access.

Detention: In some cases, containers may be held at the terminal or warehouse for extended periods due to various factors, such as customs clearance delays or pending inspections.

Load and Unload: Containers are loaded and unloaded from trucks or rail cars using specialized equipment such as cranes, forklifts, or tilters. These tools ensure smooth handling and minimize the risk of damage.

Storage: Containers may be stored at warehouses or designated storage areas until they are ready to be transported again or picked up by the consignee.

Temperature Control: For containers with temperature-sensitive cargo, such as reefer containers, temperature control systems and reefer sockets are used to maintain the desired temperature throughout the journey.

Moisture Protection: To protect against moisture and corrosion, containers may be equipped with ventilation systems or treated with special coatings. Proper moisture protection measures help to safeguard the cargo inside.

Shipping Route: The chosen shipping route plays a crucial role in the transportation process, ensuring the container reaches its destination efficiently and cost-effectively.

Demurrage: Demurrage fees may be incurred if containers are held at the terminal or warehouse for longer than the agreed-upon timeframe. It is important to adhere to the agreed terms to avoid additional costs.

Supply Chain: The transportation of ISO containers is an integral part of the global supply chain, ensuring goods can be transported worldwide.

Trucking: Trucking companies play a vital role in the transportation of ISO containers, providing the necessary equipment and expertise for safe and efficient delivery.

Vessel: For ocean transport, containers are loaded onto vessels using cranes or other lifting equipment. These vessels are specifically designed to carry containers, known as container ships, and are a cornerstone of the shipping industry.

ISO containers are equipped with various security features to ensure the safe transportation of goods. These features are designed to protect the cargo from theft, damage, and other potential risks. Let’s explore some of the key security features of ISO containers.

These security features, combined with the rigorous logistics and transportation processes within the global trade network, help to safeguard the cargo during its journey from the warehouse to the final destination. Whether transported by road, air, or sea, ISO containers play a crucial role in the secure and efficient transport of goods.

Maintenance and repairs are essential for ISO containers used in the shipping industry. Proper maintenance ensures that the containers are in good condition and meet the required standards for transport.

One important aspect of maintenance is the regular inspection of the container for any damages or signs of wear and tear. This includes checking the corner castings, chassis, and overall structure of the container. Any issues detected should be immediately repaired to avoid further damage during transport.

Another important maintenance task is the cleaning of the container. This includes removing any dirt, debris, or residue from previous shipments. Proper cleaning also helps in maintaining the container’s hygiene and prevents the growth of fungus or other contaminants.

Ventilation is another key aspect of maintenance for ISO containers. Proper ventilation ensures that the container is suitable for transporting certain goods that require airflow, such as perishable items. Ventilation also helps in eliminating any unwanted odors that may be present in the container.

ISO containers may also require repairs or maintenance specific to certain types. For example, reefer containers used for refrigerated shipments may require repairs or maintenance for the reefer unit or inverter. This ensures that the temperature control system of the container is functioning properly.

In addition, ISO containers should be properly labeled and marked to comply with regulations and facilitate easy identification. This includes labeling the container with its size, shipping line, and other relevant information. Marking the container with a unique code or number helps in tracking and managing the container throughout its journey.

Overall, proper maintenance and repairs of ISO containers are crucial for the smooth operation of the shipping industry. They ensure the safety and security of the goods being transported, as well as the efficiency of the logistics network. By following the necessary maintenance and repair procedures, shipping companies can ensure that their containers are in optimal condition for every export or import shipment.

When it comes to ISO containers, there are a wide range of customization options available to suit different shipping needs. One popular customization is the installation of an inverter, which allows for the conversion of direct current (DC) to alternating current (AC). This is particularly useful for powering electrical equipment inside the container during transportation.

To ensure the safety of the cargo and prevent damage due to friction, air bags can be installed to cushion the load. Additionally, hooks can be added to the interior walls of the container, allowing for secure attachment of goods to prevent shifting during transit.

Security is a top priority in the shipping industry, and ISO containers offer several customization options to enhance security. Twist locks can be added to securely connect containers together, forming a consolidated stack. Moreover, containers can be equipped with strong seals to prevent tampering and ensure the integrity of the cargo.

For containers that will primarily be transported by rail or truck, additional customization options are available. For rail transportation, containers can be equipped with terminal fittings that allow for easy loading and unloading onto rail cars. For trucking, the containers can be modified with specialized chassis that provide better stability and handling on the road.

Another important customization option is the addition of a reefer unit. This refrigeration unit is essential for transporting perishable goods that require a controlled temperature environment. Reefer units are equipped with ventilation systems, temperature controls, and can withstand vibrations during transport.

Additionally, ISO containers can be customized to meet specific dimensions. Overheight containers are available for cargo that exceeds the standard height restrictions, providing a solution for oversized goods. Furthermore, containers can be customized with specific sizes to optimize space and accommodate different types of cargo.

When it comes to customization options for ISO containers, the possibilities are endless. From security enhancements to temperature control and size customization, these containers can be tailored to meet the unique requirements of various industries and global trade.

ISO containers, also known as shipping containers, are not just limited to the transportation of cargo by road, rail, or sea. These versatile containers have found innovative uses in various industries and sectors.

These innovative uses of ISO containers demonstrate their adaptability and versatility beyond their traditional role in the shipping and transportation industry. From customized structures to off-grid living, these containers provide endless possibilities for various industries and sectors.

The shipping industry plays a crucial role in global trade, but it also has a significant environmental impact. ISO containers, commonly used in shipping, contribute to this impact in several ways.

One environmental concern is the friction caused by containers during transportation. Friction increases fuel consumption, leading to higher greenhouse gas emissions. To reduce friction, containers are designed with smooth surfaces and low-resistance materials.

Another environmental consideration is the use of reefer containers, which require additional energy to maintain the desired temperature for perishable goods. These containers have built-in refrigeration units that can be powered by the ship’s electrical system or by reefer sockets in ports. Efforts are being made to improve the energy efficiency of reefer containers and reduce their carbon footprint.

Customs regulations can also impact the environment by delaying the shipping process. Lengthy customs procedures can lead to inefficiencies in the logistics network, resulting in longer shipping routes and increased fuel consumption. Simplifying customs processes can help minimize the environmental impact of ISO containers.

Container handling equipment, such as tilters and corner castings, also play a role in the environmental impact of ISO containers. These devices use wire ropes and locks to secure containers during transportation. Efforts to optimize the design and materials used in these devices can help reduce energy consumption and minimize their environmental footprint.

Ventilation and moisture control are essential for maintaining the quality of goods inside containers. Proper ventilation systems, including vents and drip pans, help prevent the growth of fungi and other contaminants. This reduces the need for chemical treatments, promoting sustainability and environmental health.

Another aspect of environmental impact is the maneuverability of ISO containers on roads and in ports. Overheight and overwidth containers may require special handling, leading to additional energy consumption. Improving the design of containers and implementing better routing strategies can help enhance maneuverability and reduce the environmental impact of ISO containers.

Port infrastructure, including chassis and terminals, also contributes to the environmental impact of ISO containers. Efficient chassis designs and well-planned terminals can minimize energy consumption during the loading, unloading, and stacking of containers.

The transportation of ISO containers by vessels also has environmental implications. Vibration and sway during sea travel can lead to container damage and increased fuel consumption. Implementing effective lashing systems and optimizing vessel design can help reduce these environmental impacts.

The use of flexitanks, a type of container used for liquid transportation, can also impact the environment. Flexitanks eliminate the need for individual drums or intermediate bulk containers, reducing packaging waste. However, the proper disposal of flexitanks after use is crucial for ensuring environmental sustainability.

Overall, the environmental impact of ISO containers in the shipping industry is a complex issue involving multiple factors along the supply chain. Efforts to improve energy efficiency, reduce emissions, optimize logistics networks, and promote sustainable practices are essential for mitigating the environmental impact of ISO containers in global trade.

The shipping container is an essential element in the global logistics network. Made of strong and durable steel, these containers provide secure and tamper-proof storage and transportation for a wide range of goods. They are designed to withstand harsh weather conditions, with features such as tarpaulin covers and blast resistance.

With standardized sizes and corner castings for twist locks, shipping containers are easily maneuverable and can be efficiently transported by road, rail, or air. The containers can be stacked and secured in warehouses, depots, and on ships using twist locks, providing a seamless flow in the supply chain.

Shipping containers also offer various features to ensure the safe transport and storage of goods. Ventilation systems, such as air vents, help regulate temperature and humidity, while reefer units, equipped with reefer sockets, enable the transportation of perishable goods. The containers are also equipped with satellite tracking devices for enhanced security and monitoring during transportation.

When goods are shipped, they are loaded into the containers, and a unique seal is placed to certify the contents. The containers are then transported by a shipping company, either by land, sea, or air, with all necessary documentation, such as a bill of lading and manifest, ensuring proper handling and delivery. Demurrage and other charges may apply if the containers are not returned within the specified time.

Shipping containers play a crucial role in the global transport chain, providing a secure, efficient, and cost-effective solution for the transportation of goods. Their standardized size, strong construction, and ability to be easily integrated into the logistics network make them an essential component in the supply chain.

Shipping containers have revolutionized the way goods are transported across the globe. With their standard dimensions and sturdy construction, they offer several advantages for both import and export activities.

Shipping containers are durable and can withstand harsh weather conditions, making them ideal for long-distance transportation. They are also secure and can be easily locked to protect the cargo. Additionally, shipping containers are cost-effective as they can be reused multiple times, reducing the need for additional packaging materials.

Yes, shipping containers are considered environmentally friendly. They are made from recycled steel, which helps reduce the demand for new steel production. Additionally, using shipping containers for transportation reduces the need for traditional packaging materials, such as cardboard boxes, which helps reduce waste.

Yes, shipping containers can be easily transported on various modes of transportation. They are designed to be compatible with different methods, including ships, trains, and trucks. They can be loaded and unloaded using cranes, forklifts, or specialized equipment, making them versatile for transportation purposes.

Yes, shipping containers offer flexibility for storage and customization. They come in different sizes, with the most common being 20-foot and 40-foot containers. They can be modified and converted into various structures, such as portable offices, storage units, or even homes. This versatility makes them a popular choice for many industries.

Yes, shipping containers are a cost-effective option for transportation. Due to their durability and reusability, they can be used for multiple shipments, reducing the need for purchasing new containers or additional packaging materials. This cost savings makes shipping containers an attractive choice for businesses looking to reduce transportation costs.