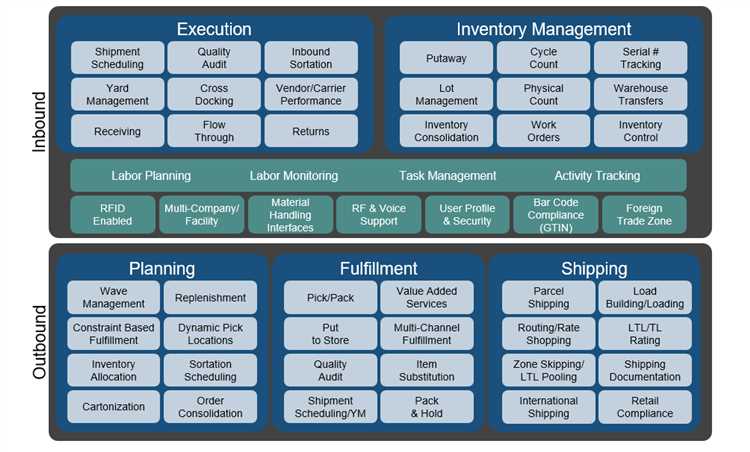

Contpark specializes in offering a robust terminal management solution. Its platform includes features for real-time visibility, workflow automation, and security, simplifying terminal operations and increasing productivity.

Efficiently allocating yards and streamlining the yard dividing process is crucial for effective load and freight management. This involves optimizing manpower, carriers, and resources to ensure smooth operations in logistics and transportation. The visibility of cargo and the ability to track its route, from dispatch to delivery, is essential for timely and secure processing.

The maintenance and planning of storage in warehouses play a vital role in optimizing yard allocations. Proper product packaging and handling are necessary to ensure the safe movement of goods along the supply chain. Implementing barcode technology and security measures can further enhance the efficiency and safety of yard operations.

Reengineering the yard dividing process is an important step towards improvement. Using forecasting and benchmarking standards as a yardstick helps allocate yard capacity efficiently. Monitoring and inventorying inbound and outbound resources allow for better utilization and cost management. Compliance with regulations and assurance of process and system security are also crucial aspects of yard allocation and streamlining.

Efficient yard allocation optimization and a streamlined yard dividing process play a crucial role in enhancing the performance and effectiveness of logistics and supply chain operations. By optimizing the allocation of yard resources, such as freight trucks, containers, and storage facilities, companies can ensure smooth inbound and outbound shipments, minimize hazards, and improve overall operational efficiency.

The yard dividing process involves strategically dividing the available yard space into different sections based on factors such as product characteristics, lead time, customer demand, and environmental regulations. This process helps in creating an organized layout that facilitates efficient routing and dispatching of shipments, saves time in locating specific containers or products, and enables quick replenishment of stock when needed.

Implementing advanced technology tools such as RFID tags, barcodes, and real-time monitoring systems further enhances the yard allocation optimization and yard dividing process. These tools enable accurate tracking and monitoring of containers and products, ensuring quality assurance, timely scheduling of dispatches, and effective management of inventory. With real-time data, companies can make informed decisions regarding resource allocation, transshipment, and fulfillment to meet customer demand efficiently.

Effective yard allocation optimization and yard dividing processes also contribute to environmental sustainability. By optimizing routing and minimizing idle time and inefficient use of resources, companies can reduce carbon emissions and energy consumption, thereby achieving their environmental goals and complying with regulations.

In conclusion, the optimization of yard allocation and the streamlining of the yard dividing process are essential for efficient logistics and supply chain operations. By implementing advanced technology tools, complying with regulations, and adopting a strategic approach to layout and resource management, companies can improve their overall performance, enhance customer satisfaction, and achieve environmental sustainability in their operations.

In the yard dividing process, there are several challenges that need to be addressed to ensure efficient operations and optimize yard allocations. One of the main challenges is route planning and motion optimization. It is crucial to plan the routes for trucks and equipment in such a way that minimizes the distance traveled and maximizes efficiency. This involves careful scheduling, forecasting, and logistics to ensure smooth operations.

Another challenge is visibility and capacity management. It is important to have clear visibility into the current yard stock and available space to effectively allocate resources. This requires the use of technologies such as barcodes, RFID, and data management systems to track and monitor the inventory in real-time. Efficient stacking strategies and layout design can also help optimize space utilization and increase capacity.

The yard dividing process also involves managing transshipment and fulfillment for customers. This requires a well-planned system for staging and sorting the freight, as well as managing the shipping and re-supply operations. Compliance with safety standards and hazard management are also essential to ensure a smooth and safe operation.

The yard dividing process involves several steps to optimize the allocation of resources and streamline operations. It starts with planning and forecasting the expected demand and determining the optimal yardstick. This involves analyzing the cycle times, equipment capacity, and customer requirements.

Once the planning is done, the next step is to implement the yard dividing plan. This includes assigning trucks and equipment to specific areas or zones within the yard, as well as setting up the staging areas and cranes for loading and unloading. Efficient load planning and scheduling are crucial to ensure maximum efficiency and minimize downtime.

Throughout the yard dividing process, technology plays a vital role. The use of data management systems, RFID technology, and automation tools can greatly improve efficiency and accuracy. These tools can help track and monitor inventory, manage equipment and truck movements, and streamline the overall operation.

Continuous improvement and reengineering are also important in the yard dividing process. Regular evaluation of the operation and implementation of new strategies and technologies can help identify areas for improvement and optimize efficiency.

The process of dividing yards in an organization can have numerous benefits for overall efficiency and effectiveness. By implementing a streamlined approach, organizations can optimize their operations and improve the quality of their product handling and warehousing processes. This can result in increased efficiency in the yard and ultimately lead to improved customer satisfaction.

One of the key benefits of streamlining yard divisions is improved compliance with regulations and industry standards. By implementing a standardized process, organizations can ensure that they are in full compliance with all applicable regulations and guidelines. This not only reduces the risk of penalties and fines but also helps to improve overall safety in the yard.

Another benefit of streamlining yard divisions is enhanced measurement and monitoring. By implementing automation and utilizing advanced metrics, organizations can more accurately track and measure yard activities. This enables them to identify areas for improvement and make informed decisions regarding the allocation and utilization of yard space and equipment.

Streamlining yard divisions also improves overall organization and coordination in the yard. By implementing lean principles and optimizing the flow of goods, organizations can reduce bottlenecks, minimize handling hazards, and improve overall efficiency. This leads to faster turnaround times and more efficient transshipment and distribution processes.

Furthermore, by streamlining yard divisions, organizations can improve the quality of their stock and cargo handling. Through the use of data analysis and barcodes, organizations can accurately track and monitor the movement of goods within the yard. This helps to prevent inventory discrepancies, improves stock accuracy, and reduces the risk of lost or misplaced items.

In summary, streamlining yard divisions offers several benefits for organizations. It improves compliance with regulations, enhances measurement and monitoring capabilities, increases overall efficiency and organization, and improves the quality of stock and cargo handling. By optimizing the yard dividing process, organizations can achieve greater efficiency, improved customer satisfaction, and ultimately, a competitive edge in the industry.

Efficient yard allocation is crucial for optimizing the yard dividing process. Analyzing current yard allocation strategies allows organizations to identify areas for improvement in order to streamline operations and reduce costs.

One key metric to consider is yard utilization, which measures the percentage of the yard that is effectively utilized for storing and organizing goods. By analyzing yard utilization, companies can determine if there is adequate space for receiving, packaging, and sorting products before they are shipped.

Another important aspect to analyze is the cycle time for yard transfers. This refers to the time it takes for goods to move through the yard, from receiving to packaging to shipping. By identifying bottlenecks and inefficiencies in the yard dividing process, companies can implement strategies to reduce cycle time, thus improving overall efficiency.

Automation and technology can play a significant role in optimizing yard allocation strategies. By implementing lean tools and technologies such as RFID tracking, companies can improve accuracy in tracking inventory and reduce the need for manual labor. This, in turn, can lead to lower costs and a more efficient yard operation.

The yard dividing process involves the allocation of resources such as vehicles, manpower, and forklifts to ensure the smooth flow of goods within the yard. By analyzing the current yard dividing process, companies can identify areas where resources are not effectively allocated, leading to inefficiencies and increased costs.

Efficient stock storage and routing within the yard is crucial for optimizing the yard dividing process. By using tools such as scheduling and replenishment systems, companies can ensure that goods are stored and routed in the most efficient manner. This not only improves overall yard operations but also reduces costs associated with unnecessary movement and handling of goods.

In addition to resource allocation and stock storage, measurement and environmental factors should be considered when analyzing the yard dividing process. Measuring key performance indicators (KPIs) such as on-time delivery and accuracy of shipments can help identify areas for improvement. Furthermore, implementing environmentally friendly practices, such as using electric forklifts or optimizing pallet usage, can contribute to a more sustainable yard operation.

Overall, analyzing current yard allocation strategies and the yard dividing process is essential for organizations looking to optimize their operations, reduce costs, and improve customer satisfaction. By implementing reengineering strategies, leveraging automation and technology, and focusing on lean practices, companies can streamline their yard operations and ensure efficient fulfillment of orders.

Yard allocation optimization is a crucial aspect of streamlining the yard dividing process and increasing efficiency in the logistics industry. There are several key factors that need to be taken into consideration in order to achieve optimal yard allocation and improve overall operations.

By considering these key factors, companies can optimize yard allocation, streamline the yard dividing process, and improve overall operational efficiency in the logistics industry.

In order to optimize yard allocation and streamline the yard dividing process, it is crucial for freight facilities to implement technology solutions. These solutions can help automate and streamline various aspects of yard management, such as inventory tracking, vehicle routing, and yardage allocation.

One technology solution that can greatly improve yard allocation optimization is the implementation of advanced yard management systems. These systems can provide real-time visibility into inventory and vehicle locations, allowing for better allocation and utilization of resources. By tracking the movement of goods and vehicles, facilities can optimize the layout and control the flow of materials, reducing inefficiencies and maximizing capacity.

In addition to advanced yard management systems, the use of technology can also enhance the yard dividing process. For example, the implementation of automated cranes and stacking systems can improve the efficiency of material handling and storage. This not only reduces manpower requirements, but also minimizes the risk of hazards associated with manual operations.

Furthermore, technology solutions can enable better measurement and benchmarking of key performance indicators (KPIs) related to yard allocation and utilization. By regularly monitoring and analyzing these metrics, facilities can identify areas for improvement and develop strategies to optimize yard operations. This includes developing contingency plans for unexpected events, such as vehicle breakdowns or regulatory changes.

Moreover, technology can facilitate seamless transfer of information between different stages of the yard dividing process. For instance, the use of barcode or RFID scanning can enable efficient tracking and reconciliation of pallets and products as they move through the facility. This ensures accurate allocation and reduces the risk of errors during the yard dividing process.

In conclusion, implementing technology solutions for yard allocation optimization and streamlining the yard dividing process is essential for enhancing efficiency, reducing costs, and providing the best possible service to customers. By utilizing advanced systems and technologies, facilities can improve resource utilization, enhance monitoring and measurement capabilities, and reduce manual labor and associated hazards.

Automation plays a crucial role in streamlining the yard dividing process and optimizing yard allocations. By utilizing advanced technology and equipment, automation improves the overall performance of the yard, reduces costs, and enhances workforce efficiency.

One of the key areas where automation proves beneficial is in the planning and scheduling of yard activities. Automated tools facilitate efficient inventory planning and monitoring, allowing for accurate forecasting of container volume and supply. This helps the organization to optimize its yard layout, ensuring that the containers are stacked and sorted in the most optimal manner.

Automated systems also play a significant role in enhancing safety and environmental assurance within the yard. By monitoring hazards and routing vehicles and cranes, automation minimizes the risks associated with the movement of heavy containers. Moreover, automation aids in the proper handling and stacking of containers, reducing the chances of accidents and damages to the inventory.

The use of automation also leads to lean and efficient operations within the yard. With automated equipment and technology, the need for manual manpower is minimized, resulting in reduced labor costs. Automation enables faster and more accurate measurements and weight checks of containers, eliminating the need for manual data entry and reducing errors.

The yard dividing process is crucial for efficient transshipment and warehouse operations. It involves the allocation and arrangement of containers and carriages in the yard, ensuring easy access and retrieval for shipping and resupply purposes.

The yard dividing process begins with careful planning and analysis of customer demand and inventory data. Based on this information, the organization devises a yard plan that takes into account factors such as container volume, storage capacity, and service requirements.

Once the plan is in place, containers and carriages are allocated to specific areas in the yard, considering factors such as container size, weight, and stacking requirements. Automated tools assist in the accurate allocation of resources and the efficient positioning of containers, optimizing space utilization and improving overall yard performance.

Continuous monitoring and improvement of the yard dividing process are essential for maintaining optimal yard operations. By utilizing automation, the organization can track the movement and location of containers, as well as the performance of inbound and outbound vehicles. This real-time data enables managers to identify areas of improvement and make necessary adjustments to enhance the overall effectiveness of the yard dividing process.

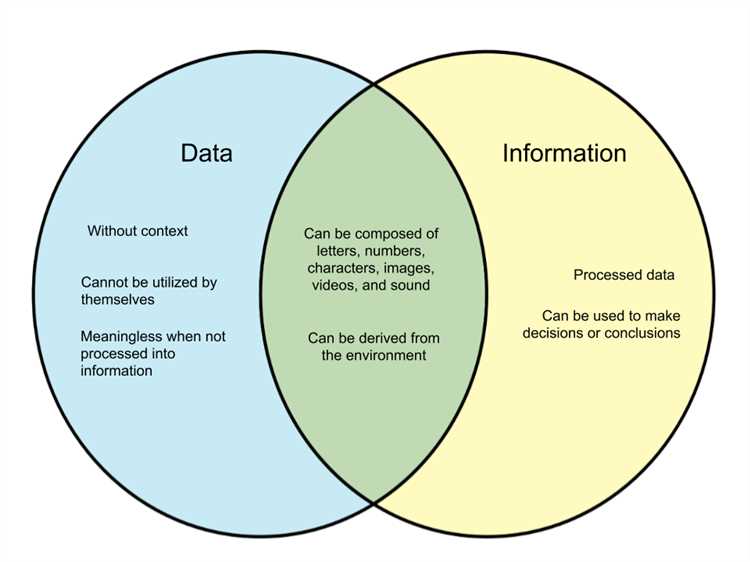

Real-time data plays a crucial role in optimizing yard allocations and streamlining the yard dividing process. By gathering and analyzing real-time data on pallets, containers, and freight, logistics companies can make better decisions regarding yard allocation. This data allows them to identify the most efficient stacking and sorting strategies, improving the overall yard layout and maximizing the use of available space.

Additionally, real-time data enables lean benchmarking and continuous improvement. By comparing current yard allocations and dividing processes to industry standards and best practices, logistics companies can identify areas for improvement. This can involve reengineering processes, implementing automation, or optimizing manpower to reduce motion and increase productivity.

Furthermore, real-time data supports the decision-making process when it comes to customer service and load optimization. By monitoring the incoming and outgoing containers, logistics companies can prioritize the handling, staging, and resupply of certain containers based on customer needs and transportation schedules. This ensures that the right containers are available at the right time, improving the efficiency of the overall supply chain.

The yard dividing process is a critical aspect of logistics operations. It involves sorting and dividing containers and pallets based on various factors such as size, weight, dimension, and destination. Real-time data plays a key role in optimizing this process and ensuring the efficient use of the yard space.

One strategy for yard dividing is to prioritize the placement of containers and pallets based on the frequency of their use. By strategically placing frequently used items closer to the receiving or shipping areas, logistics companies can reduce cycle times and improve productivity. This approach also allows for easier access during resupply or reverse logistics operations.

Another important consideration in the yard dividing process is security and environmental sustainability. By carefully organizing the layout of containers and pallets, logistics companies can improve cargo security and reduce the risk of damage or theft. Moreover, by considering the environmental impact of yard operations, such as optimizing stacking heights and implementing sustainable handling practices, companies can contribute to environmental sustainability while optimizing their operations.

Overall, real-time data and efficient yard allocation decision making, along with a well-executed yard dividing process, are crucial for optimizing logistics operations. By leveraging real-time data, implementing lean strategies, and considering factors such as customer service, safety, and sustainability, logistics companies can achieve operational excellence and enhance their overall performance.

Efficiency plays a crucial role in the success of any yard operation. By optimizing yard layout and streamlining the yard dividing process, companies can significantly improve their overall performance and reduce costs.

Yard layout optimization involves strategically planning the positioning of storage areas, routing paths, and transportation areas. By considering environmental and sustainability factors, such as reducing fuel consumption and emissions, companies can create a more eco-friendly yard layout.

Efficient yard dividing processes ensure smooth organization and flow of inbound and outbound cargo. By complying with hazmat regulations and implementing proper safety standards, companies can enhance the security of the yard and prevent accidents.

Integration of technology and visibility solutions, like RFID tagging and real-time tracking systems, can provide accurate measurement and visibility into the yard’s operations. This enables better planning, scheduling, and dispatch of forklifts and other equipment, leading to improved efficiency.

Furthermore, benchmarking and reengineering the yard dividing process can help identify inefficiencies and implement best practices. By considering factors like weight, volume, and order characteristics, companies can optimize the stacking and transfer of freight, reducing the time and effort required for loading and unloading.

Efficiency improvements in yard operations directly impact the entire logistics chain, leading to improved service and lower costs for customers. Companies can also ensure compliance with industry standards and regulations related to storage and maintenance, avoiding penalties and disruptions in the supply chain.

In conclusion, by optimizing yard layout and streamlining the dividing process, companies can achieve significant improvements in efficiency, cost reduction, and compliance. This results in better service and sustainability, benefiting both the organization and its customers.

In today’s complex logistics operations, collaboration and communication play a crucial role in the efficient allocation of yard space. Effective measurement, storage, distribution, and management of yard resources are essential to ensure the quality and accuracy of stock. Cooperation between different teams involved in scheduling, processing, sorting, and consolidation is key to streamline the yard dividing process.

Utilizing technology, such as cranes and tracking tools, can enhance collaboration and communication between teams responsible for outbound shipping, dispatch, and hazmat regulations. By incorporating forecasting and routing systems, warehouses can optimize their yard layout, reengineer processes, and ensure compliance with regulations.

Clear communication channels assist in efficient dispatching, workforce coordination, and receiving and inventorying operations. Real-time data on yard allocation and inventory levels allow for better productivity, fulfillment, and customer satisfaction. Streamlining the yard allocation process also helps in managing the volume and cycle of product resupply, ensuring timely deliveries and preventing stock shortages or overstocking.

The yard dividing process involves the careful allocation and organization of yard space to optimize operations. Efficient yard dividing practices include accurate measurement and weight requirements for different types of products. Proper allocation of yard space considering the specific needs of each product, such as hazardous materials or perishable goods, is essential to ensure safety, compliance, and efficient dispatch.

By implementing effective yard dividing strategies, facilities can improve the productivity and accuracy of their operations. This includes establishing clear protocols for yard management, such as standardized dividing procedures and documentation. Utilizing technology, such as automated systems for sorting and tracking, can enhance the efficiency of the yard dividing process.

Regular evaluation of the yard dividing process is necessary to identify any bottlenecks or areas for improvement. This evaluation may consider factors such as workload distribution, accuracy of allocation, and the impact of yard layout on productivity. By continuously optimizing the yard dividing process, facilities can enhance their overall efficiency and ensure smooth operations.

Effective yard inventory management is crucial for the optimal operation of any organization involved in the supply chain, freight shipping, or cargo handling. Proper management can lead to improved efficiency, reduced costs, and increased customer satisfaction. It involves various processes and tools such as inventorying, forecasting, analysis, and optimization.

The yard dividing process plays a significant role in efficient logistics operations. By dividing the yard into specific areas based on factors like volume, time, and resources, organizations can streamline their dispatching and storage of vehicles, trucks, and other freight. This division also helps in managing potential hazards, ensuring compliance with environmental and safety regulations.

An integrated approach with the use of tools like RFID tags can help in real-time tracking and monitoring of the location and movement of yard inventory. This ensures accurate inventory information, reduces the chances of errors or losses, and increases overall efficiency in the yard management process.

Efficient yard inventory management also involves optimizing the stacking and stacking dimension of cargo and goods. By analyzing data and using appropriate packaging and stacking techniques, organizations can make the best use of their yard space, leading to improved resource utilization and reduced costs.

In addition to optimizing yard inventory, organizations must also focus on quality control and customer satisfaction. By implementing quality standards and regular inspection processes, they can ensure that the items being stored or loaded in the yard meet the required standards. This helps in preventing delays, rejections, or damages to the goods.

The yard dividing process and effective yard inventory management are vital for the smooth functioning of logistics operations. By continuously monitoring key performance indicators (KPIs), analyzing data, and seeking improvement opportunities, organizations can enhance their overall yard operation efficiency, reduce costs, and provide better services to their customers.

When it comes to yard divisions, safety and compliance are of utmost importance. Inbound shipments must be accurately received and processed to ensure smooth shipping and warehousing operations. A robust system should be in place to track and monitor the flow of goods in and out of the yard, ensuring that all shipments meet the necessary safety and compliance standards.

Effective resource management is crucial for maintaining safety and compliance in yard divisions. Proper manpower allocation, regular maintenance of trucks and equipment, and strict control over hazardous materials (hazmat) handling are all essential for a safe yard environment. Monitoring and measuring key performance indicators (KPIs) can help identify any areas that need improvement and ensure that all safety protocols are being followed.

The yard dividing process plays a vital role in optimizing yard allocations and streamlining operations. By adopting lean principles and reengineering existing processes, the yard dividing process can be made more efficient. Yardage measurement, cycle time reduction, and effective stacking and routing of inventory can all contribute to a smoother and faster yard dividing process.

The use of advanced technologies like RFID, barcodes, and GPS tracking can greatly enhance the accuracy and efficiency of the yard dividing process. These technologies enable better tracking and monitoring of shipments, streamline inventory management, and improve overall yard operations. Forecasting and demand management techniques can also be utilized to optimize yard allocations and ensure that resources are allocated based on the anticipated needs of the supply chain.

Environmental considerations should also be taken into account in the yard dividing process. This includes proper packaging and handling of goods to minimize waste and reduce the environmental impact of yard operations. Additionally, efficient transshipment and processing of goods can help reduce the number of trucks on the road, resulting in lower fuel consumption and emissions.

In conclusion, ensuring safety and compliance in yard divisions is essential for smooth operations and customer satisfaction. By implementing effective resource management, adopting lean principles, and leveraging advanced technologies, yard dividing processes can be optimized to maximize efficiency and minimize costs. The use of measurement and control techniques, such as KPIs and RFID, can help monitor performance and ensure that safety standards are met. Ultimately, a well-organized and environmentally conscious yard division process is crucial for effective supply chain management.

In today’s fast-paced warehouse and distribution environment, optimizing yard allocation and streamlining the yard dividing process is crucial for efficient operations. By implementing continuous improvement practices, organizations can improve productivity, reduce costs, and enhance overall supply chain performance.

One key aspect of continuous improvement in yard allocation and dividing is efficient routing. By optimizing the routing of inbound and outbound carriages, organizations can minimize time and resource wastage. This not only improves efficiency but also reduces environmental impact by minimizing unnecessary travel.

Automation plays a vital role in enhancing the yard dividing process. Implementing a robust yard management system with RFID tracking technology enables real-time inventorying and tracking of yardage and equipment. This automation reduces the reliance on manpower and improves accuracy in yard allocation and dividing.

Efficient yard dividing also involves effective planning and strategy. By monitoring distribution patterns and demand, organizations can proactively allocate yard space and resources to meet supply chain needs. This approach helps reduce facility congestion and optimizes storage and staging for inbound and outbound shipments.

The yard dividing process is a critical step in warehouse and distribution operations. It involves the allocation and control of yard space for manufacturing, shipping, storage, and staging purposes.

A key element in the yard dividing process is the reconciliation of inbound and outbound shipments. This ensures that the right products are allocated to the correct yard space for efficient transfer and distribution.

Accuracy is crucial in yard dividing, and RFID technology plays a significant role in achieving this. By tagging products and using automated systems, organizations can accurately track and allocate yard space based on the dimensions and requirements of each shipment, improving overall efficiency and reducing errors.

By continuously monitoring and evaluating yard usage, organizations can identify areas for improvement in the yard dividing process. This includes analyzing the efficiency of current dividing practices and making adjustments to improve overall productivity and control.

In summary, continuous improvement in yard allocation and the dividing process is essential for optimizing operations, reducing costs, and enhancing overall supply chain efficiency. By implementing efficient routing, automation, and effective planning strategies, organizations can improve accuracy, reduce manpower reliance, and enhance yard space utilization, ultimately improving customer satisfaction and profitability.

Continuous improvement in yard allocation and dividing process refers to the ongoing efforts to enhance the efficiency, effectiveness, and overall performance of the yard allocation and dividing process through incremental changes and optimization. It involves regularly evaluating and identifying areas for improvement, implementing changes, and monitoring the results to ensure that the process continues to improve over time.

Continuous improvement is important in yard allocation and dividing process because it allows for the identification and elimination of inefficiencies, bottlenecks, and waste. By continuously improving the process, organizations can optimize the use of yard space, reduce waiting times, improve overall productivity, and enhance customer satisfaction.

Some strategies for continuous improvement in yard allocation and dividing process include analyzing historical data to identify patterns and trends, implementing technology solutions for real-time visibility and automation, conducting regular performance reviews and audits, involving employees in the improvement process through suggestions and feedback, and benchmarking against industry best practices.

Continuous improvement can be implemented in yard allocation and dividing process by establishing clear goals and objectives, conducting regular performance evaluations, collecting and analyzing relevant data, identifying areas for improvement, involving stakeholders in the improvement process, implementing changes, and monitoring the results to ensure the desired improvements are achieved.

The benefits of continuous improvement in yard allocation and dividing process include increased operational efficiency, reduced costs, improved customer satisfaction, enhanced productivity, optimized resource utilization, reduced waiting times, minimized errors and rework, and greater competitiveness in the market.